High-rise residential long-span interval corridor high-altitude formwork steel platform construction method

A high-rise residential, large-span technology, applied in formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problems of lack of operability, long cycle, high risk, etc., to increase the use of span Scope, easy installation and dismantling, good molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

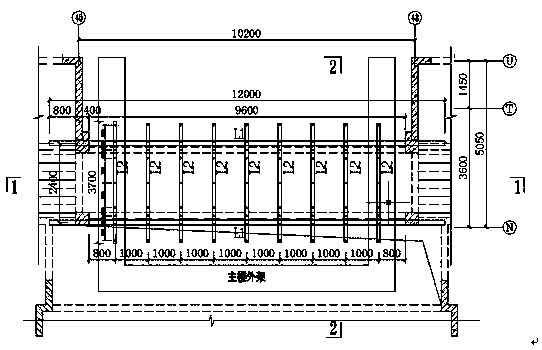

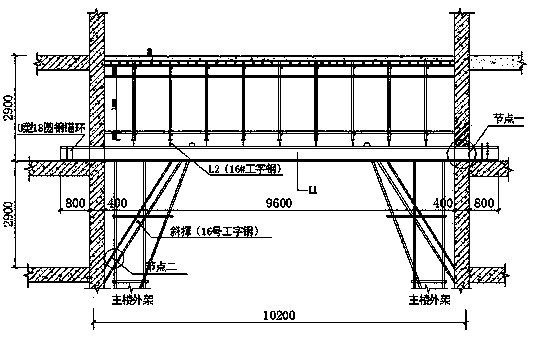

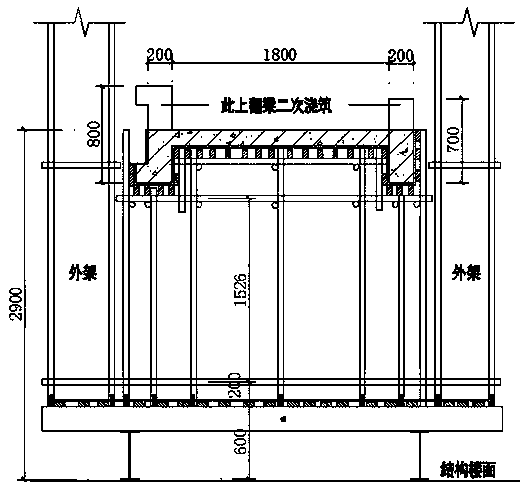

[0041] Example 1: see figure 1 , a construction method for a high-altitude formwork steel platform with a large-span interval corridor in a high-rise residential building, the construction method includes the following steps:

[0042] Step 1: Deepening design and processing of steel platform;

[0043] Step 2: hoisting and anchoring of the steel main girder;

[0044] Step 3: Installation of steel secondary beams;

[0045] Step 4: Diagonal support setting of steel main girder;

[0046] Step 5: plane protection setting;

[0047] Step 6: erection of the outer protective frame;

[0048] Step 7: Formwork support frame erection;

[0049] Step 8: Beam and slab formwork installation;

[0050] Step 9: Binding of beam and slab reinforcement;

[0051] Step 10: concrete pouring;

[0052] Step 11: Template removal;

[0053] Step 12: Corridor decoration construction;

[0054] Step 13: Remove the outer frame;

[0055] Step 14: Steel beam removal.

[0056] The step 1: deepening des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com