Construction method for overall support removal

A construction method and overall technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as slow construction speed, large construction site, and inability to carry out construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

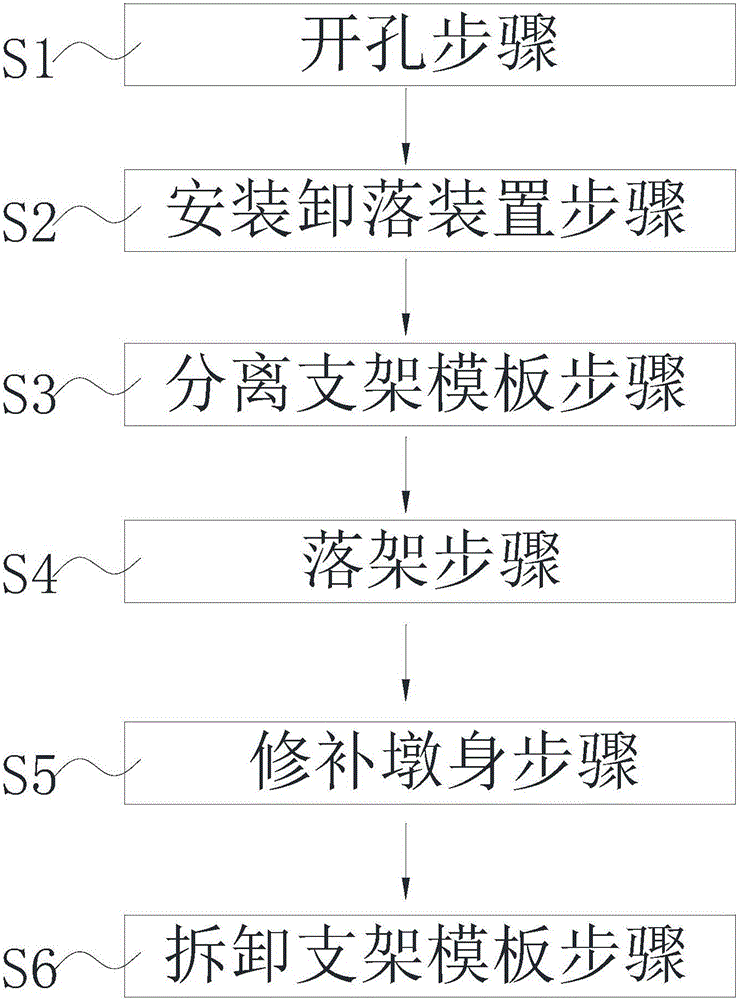

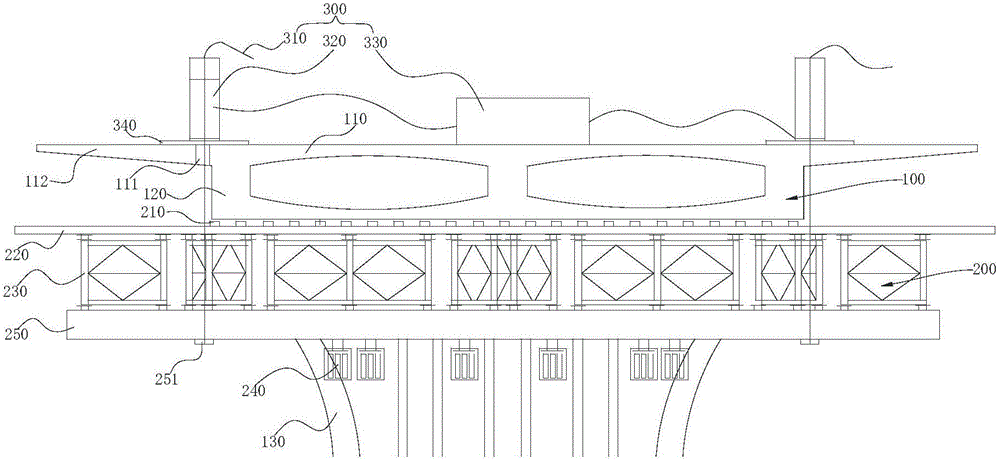

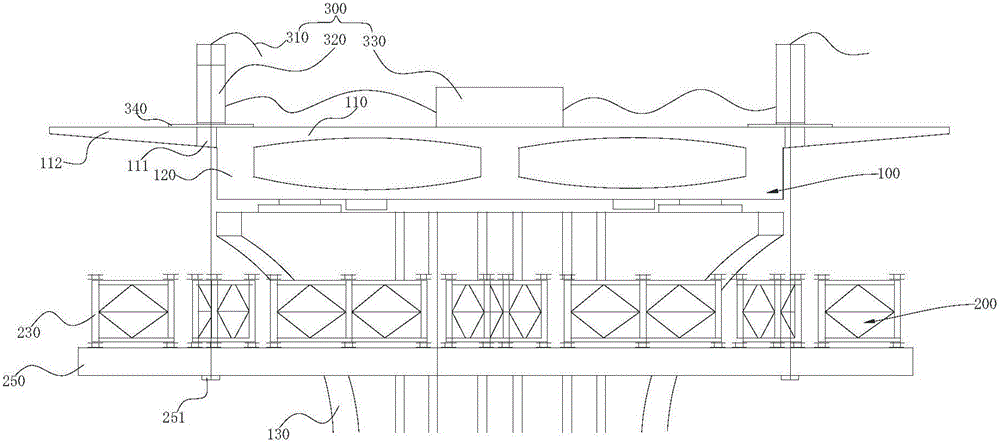

[0026] see figure 1 and figure 2 , the present embodiment provides a construction method for supporting the overall falling frame, which is mainly used for dismantling the support template 200 of the cast-in-place box girder 100. The cast-in-place box girder 100 is a kind of middle beam in bridge engineering, and the interior is hollow, with two sides on the upper part. The flange 112 is similar to a box, hence the name.

[0027] The cast-in-place box girder 100 in this embodiment includes a beam surface 110, a beam bottom 120 and a pier body 130, wherein the beam surface 110 is fixedly connected to the beam bottom 120, the pier body 130 is fixedly connected to the beam bottom 120, and the beam surface 110 and the beam bottom 120 is arranged coaxially, and the width of the beam surface 110 is greater than the width of the beam bottom 120 , so that both ends of the beam surface 110 protrude from the beam bottom 120 to form the flange 112 of the beam surface 110 . During the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com