One-time forming construction process of embedded distribution box

A construction technique and technology for distribution boxes, which are applied in the direction of electrical components, cable installation, cable installation devices, etc., can solve the problems of different sizes of gaps reserved around the box body, gap filling is not dense, and a large amount of material waste, etc., Achieve the effects of reducing labor and material costs, shortening construction time, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0029] As shown in the figure, a one-time molding construction process of a pre-embedded distribution box, the specific steps are:

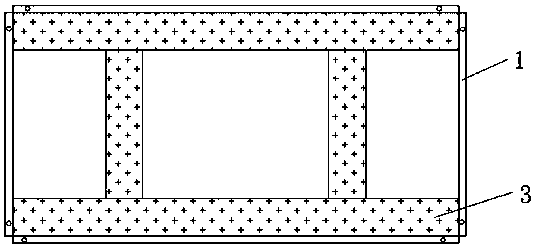

[0030] 1) The holes on the upper and lower sides of the pre-embedded distribution box 1 are sealed with plastic covers;

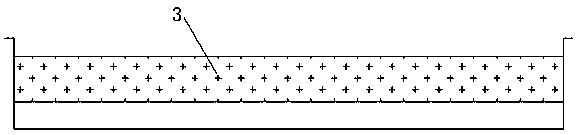

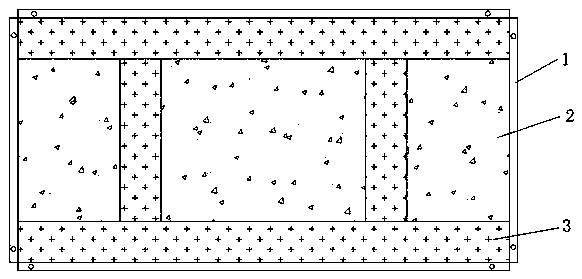

[0031] 2) Use wooden squares 3 to assemble the support frame inside the embedded distribution box 1, and the distance between the support frame and the opening plane of the embedded distribution box 1 is A;

[0032] 3) Fill the rest of the space inside the pre-embedded distribution box 1 except for the support frame with filler 2, and the distance between the upper end surface of the filler 2 and the surface of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com