Support removal device and method as well as model printer

A technology of models and supports, applied to 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve problems such as time-consuming, inability to separate supports, and inefficient removal methods, and achieve the effect of improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

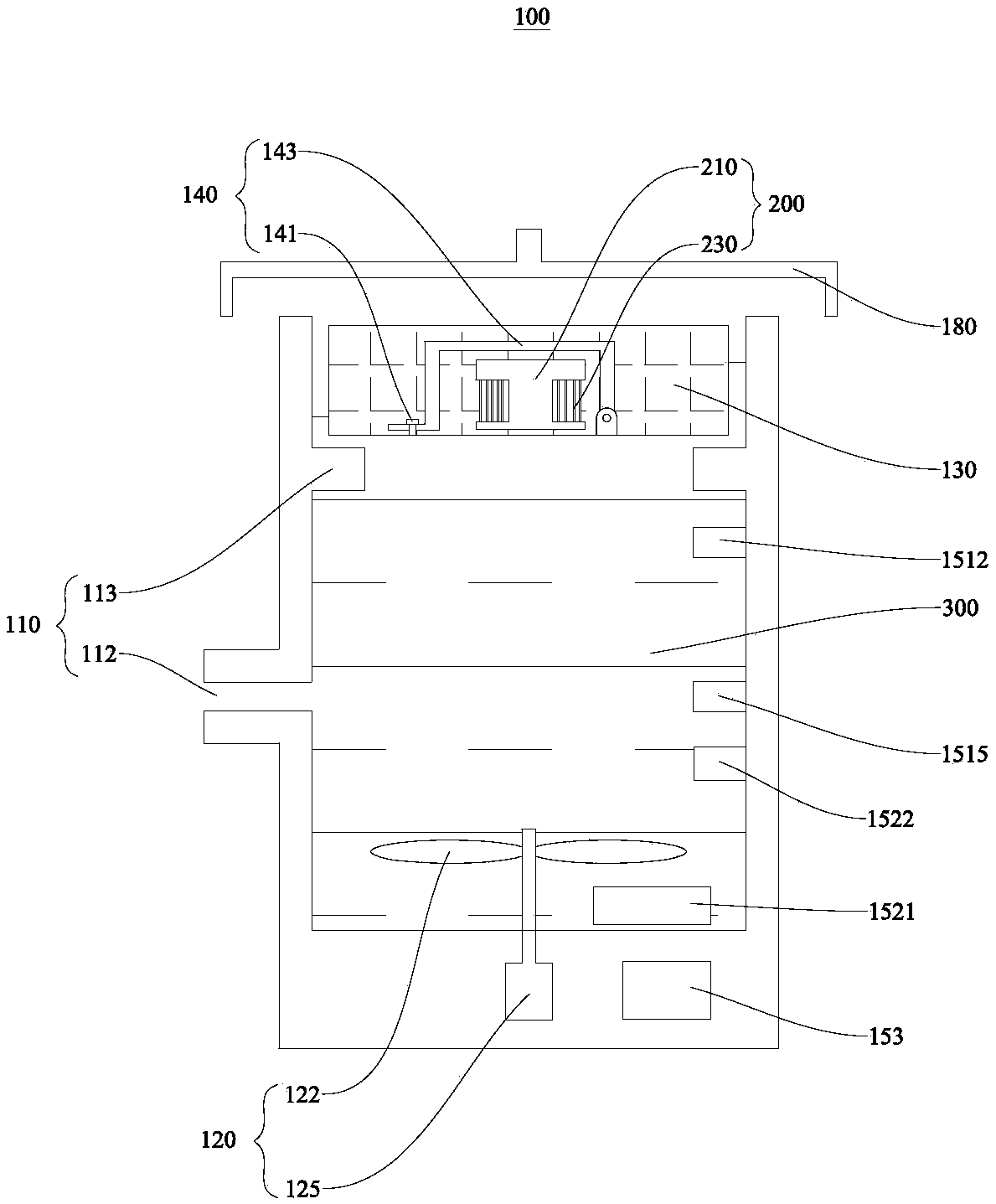

[0034] Please refer to figure 1 , figure 1 A schematic structural diagram of the support removal device 100 provided in the first embodiment of the present invention.

[0035] The printing model 200 includes a model body 210 and a support member 230 connected to each other. The support member 230 is used to prevent the model body 210 from falling during the printing process. After the printing is completed, the support member 230 needs to be removed to obtain the model body 210 . The support removing device 100 is used to remove the support 230 of the printed model 200 , and its removal efficiency is high, and the support 230 can be separated from the printed model 200 .

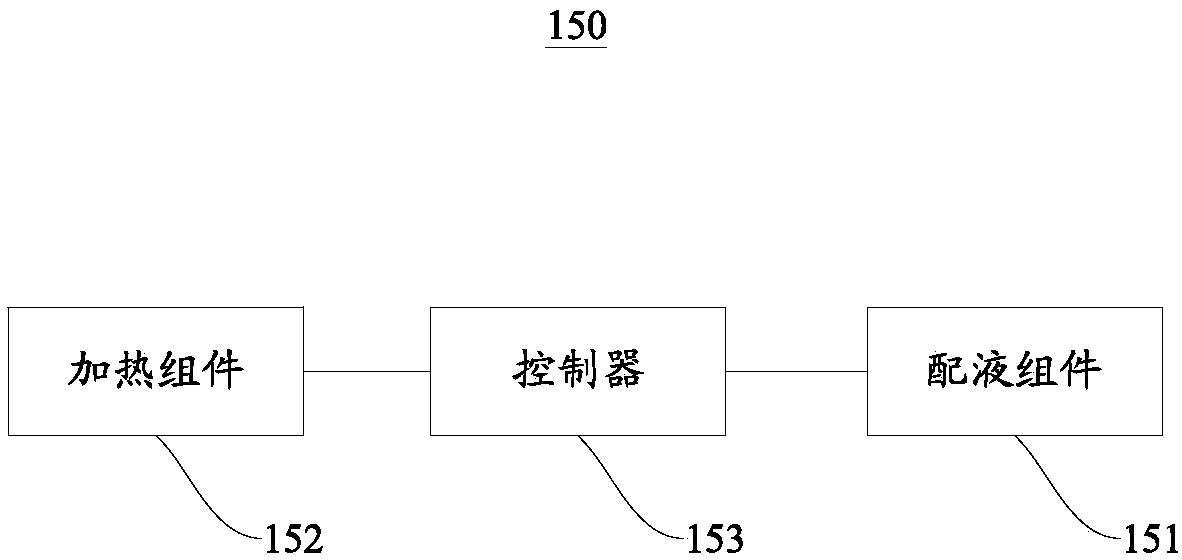

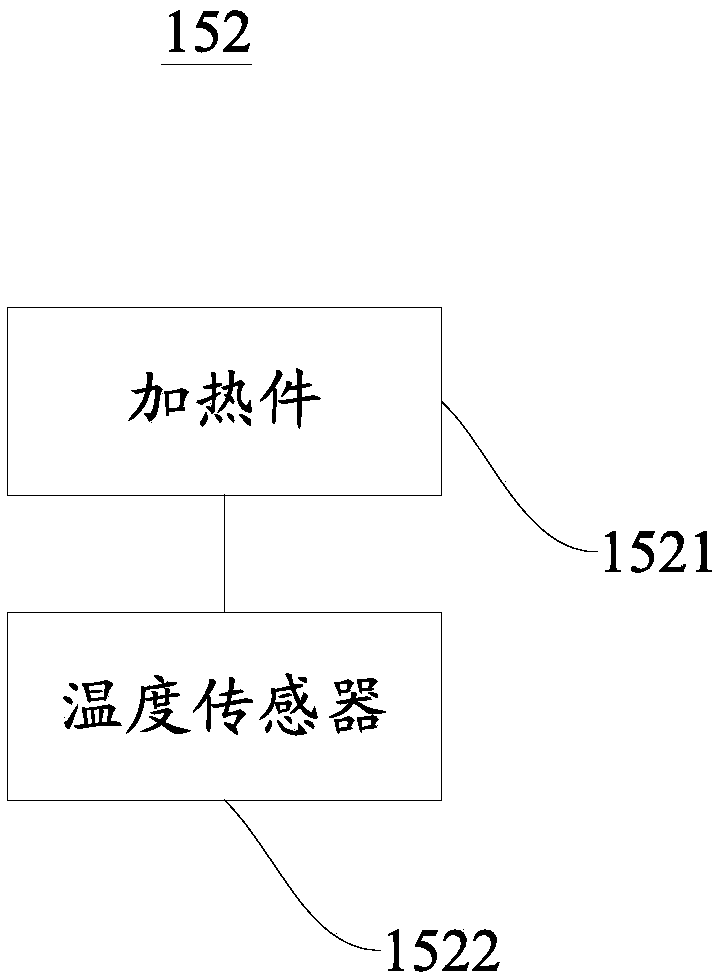

[0036]The support removal device 100 includes a support removal tank 110, an agitator 120 and a model support 130, the agitator 120 includes a stirring drive member 125 and a stirring impeller 122 connected to each other, the stirring drive member 125 is installed in the support removal tank 110, and the mo...

no. 2 example

[0062] Please refer to Figure 5 , Figure 5 A block diagram of the model printer 900 provided for the second embodiment of the present invention.

[0063] The model printer 900 includes a host computer 500 and a support removal device 100 as provided in the first embodiment. The host computer 500 is electrically connected to the controller 153, and the host computer 500 controls the activation or shutdown of the support removal device 100, so as to realize the printing of the support member 230 of the model 200. removal.

[0064] The operating principle of the model printer 900 provided by the second embodiment is:

[0065]The printing model 200 is fixed on the model support 130, the host computer 500 controls the support removal device 100 to start, and the dissolving solution 300 is added to the support removal tank 110 through the liquid distribution component 151, and the agitator 120 drives the dissolving solution 300 to advance to the printing model 200, so that the p...

no. 3 example

[0069] see Figure 6 , Figure 6 A schematic block diagram of a support removal method provided in the third embodiment of the present invention; the support removal method is used to remove the support member 230 of the printing model 200 in the dissolving solution 300, and includes the following steps:

[0070] Step S101 , stirring the dissolving solution 300 , and forming a vortex and negative pressure to push the dissolving solution 300 toward the support member 230 . When the dissolving solution 300 advances toward the support 230 , the flow of the dissolving solution 300 near the printing model 200 is accelerated, and the removal efficiency of the support 230 is improved.

[0071] Step S102 , the dissolving solution 300 is rotated under stirring, and has a centrifugal force away from the printing model 200 , and the rotating dissolving solution 300 drives the supporting member 230 of the dissolving part to separate from the printing model 200 . On the one hand, the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com