Method for mounting trestle bridge segment box girder

An installation method and technology for viaducts, applied in the direction of erecting/assembling bridges, bridges, and bridge construction, etc., can solve problems such as too small curves, and achieve the effect of easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

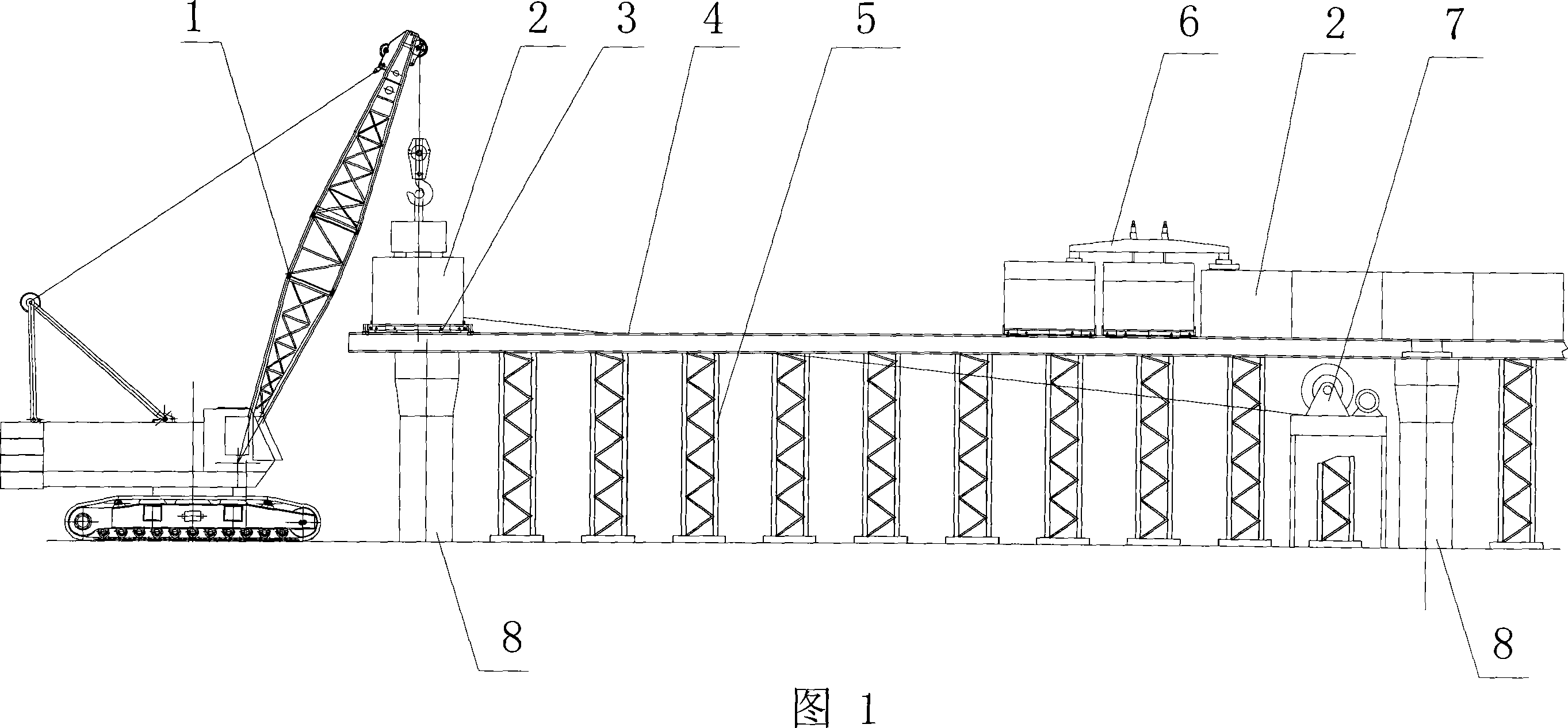

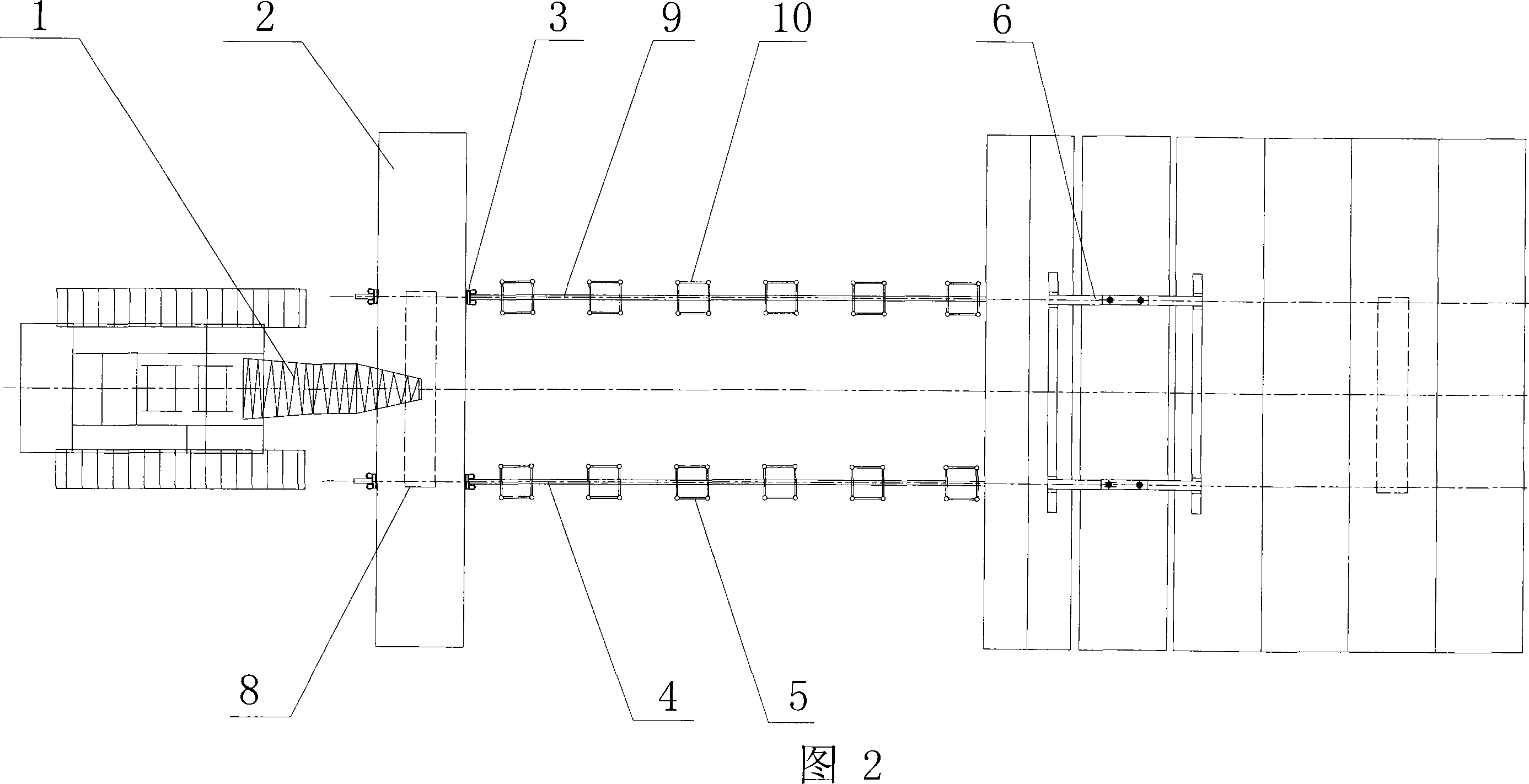

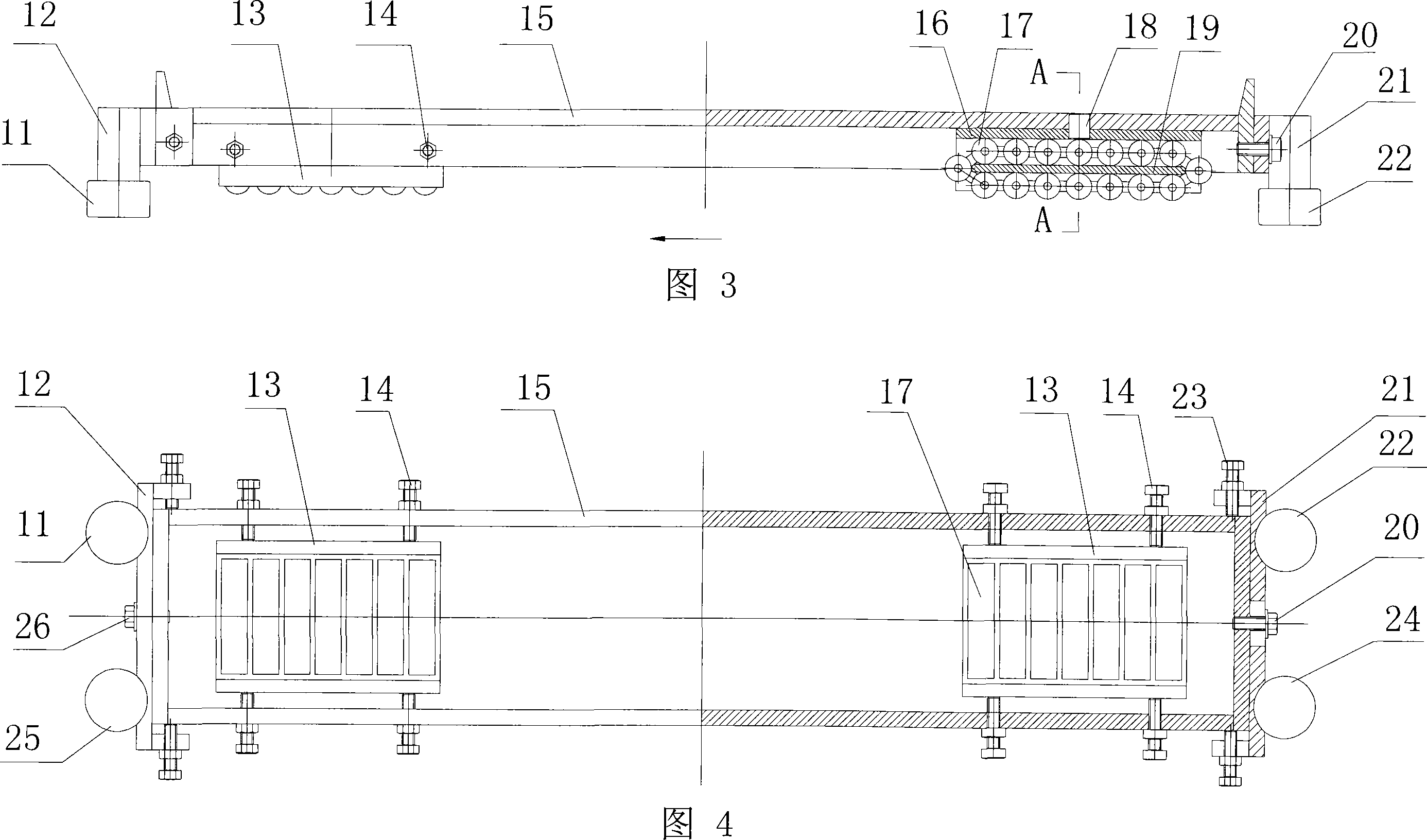

[0039] As shown in Figure 1 and Figure 2, the installation method of the viaduct section box girder includes the following steps:

[0040] 1) Set up the first row of support frames 5 and the second row of support frames 10 along the longitudinal tower between two adjacent front and rear piers 8, and then erect (fix) the first row of support frames 5 and the second row of support frames 10 One guide rail 4, the second guide rail 9, the two ends of the first guide rail 4, the second guide rail 9 are respectively arranged on two adjacent bridge piers 8 (the top of the bridge piers is provided with embedded parts, by which the first guide rail 4 , the second guide rail 9 is connected with the pier to improve the stability of the first row of support frames 5 and the second row of support frames 10); the first guide rail 4 and the second guide rail 9 are respectively equipped with vertically moving trolleys 3, 2 vertically The mobile trolley 3 is connected with the traction wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com