Composite anchoring structure on guyed tower end of cable-stayed bridge

An anchoring structure and end plate technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of increasing high-altitude prestressed construction links, reducing structural durability, and slow construction speed, so as to improve bearing capacity and construction speed , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

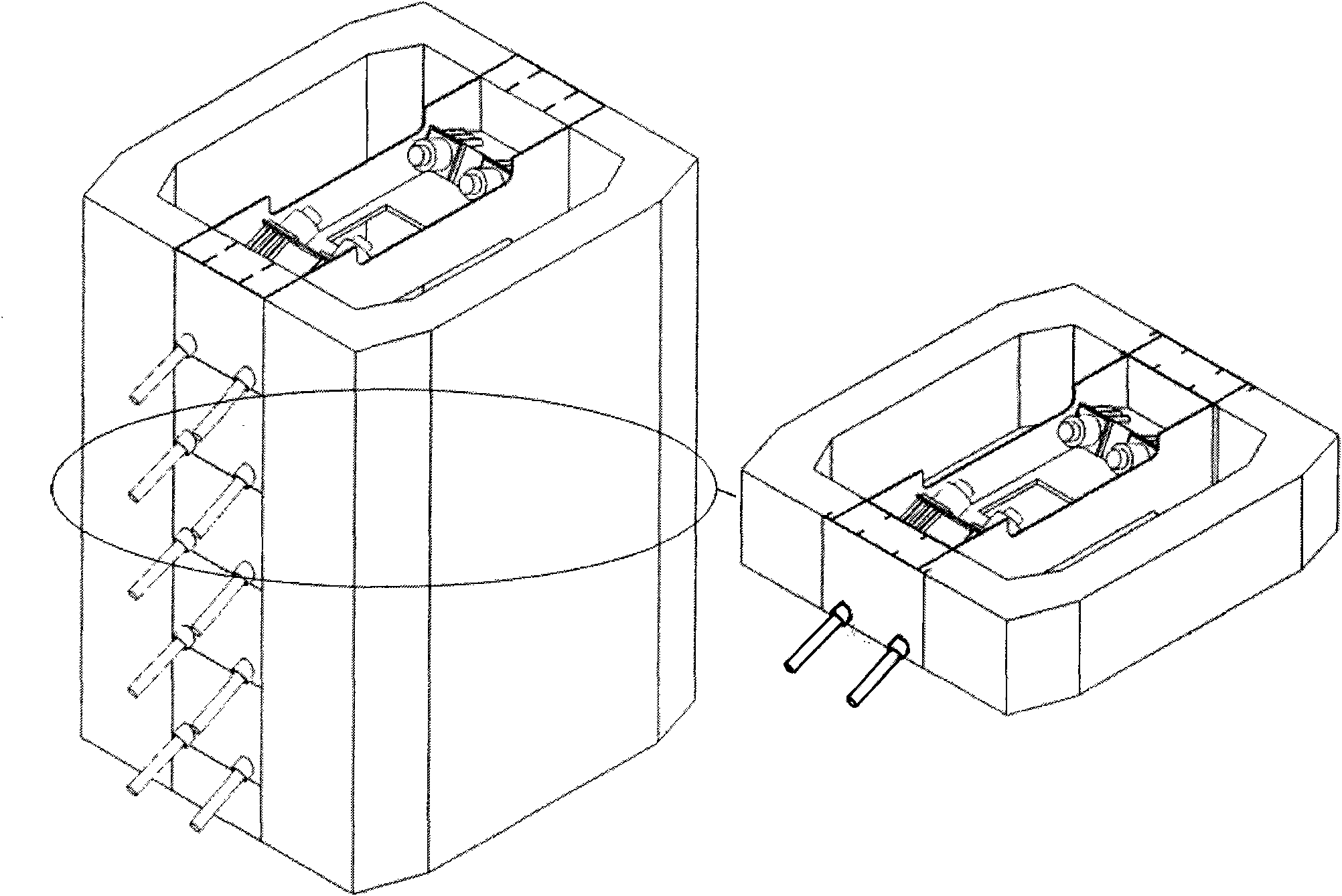

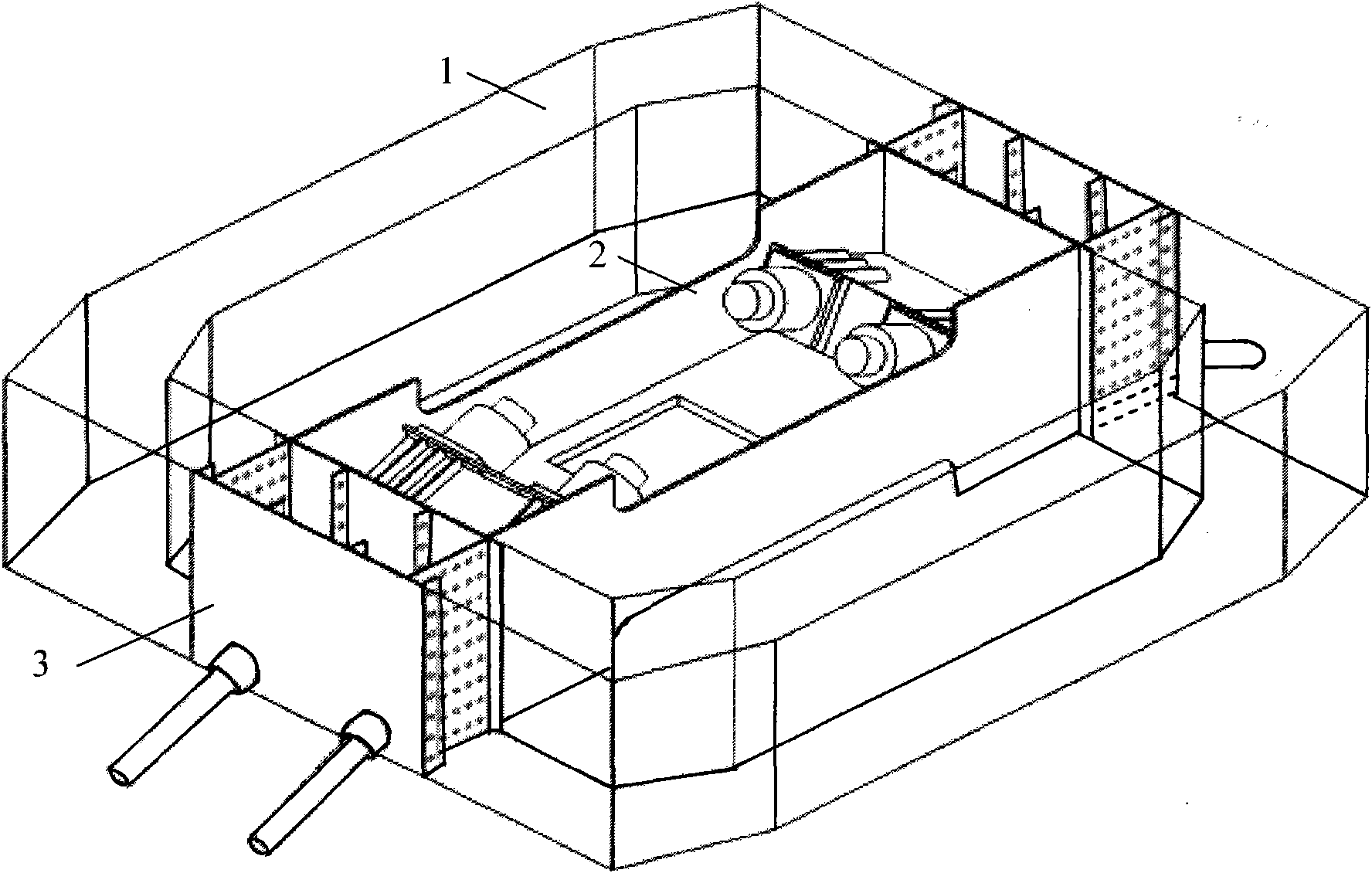

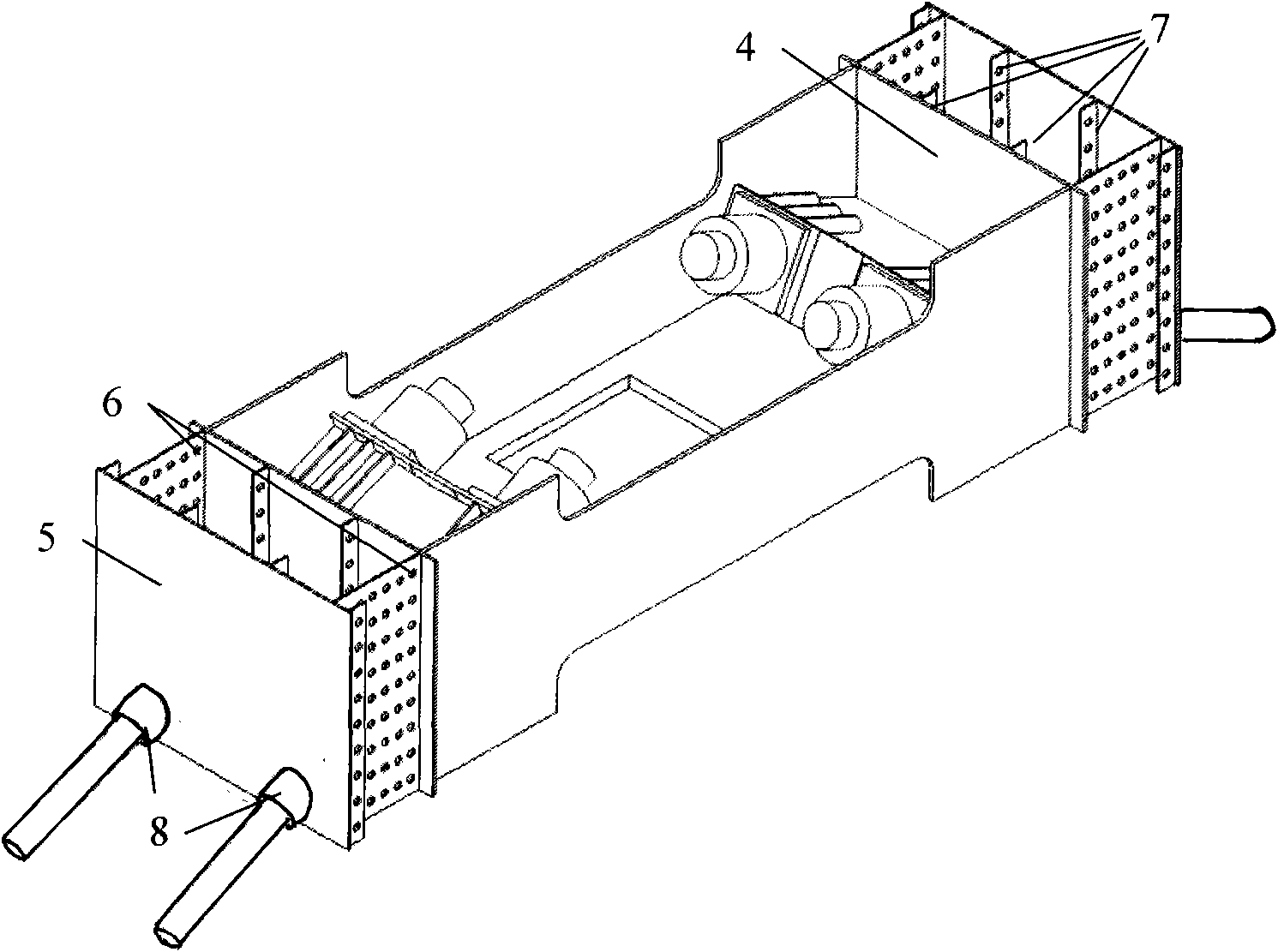

[0045] Such as figure 1 and figure 2 , the steel anchor box 2 and the end box chamber 3 are processed and integrated in the factory. After being transported to the construction site, according to the hoisting capacity, several sections of the steel anchor box are assembled on the ground and then hoisted or a single section is hoisted and positioned and then spliced on the tower. Segment splicing can be bolted or welded. After the steel anchor box is positioned, the reinforcement cage and the tower wall formwork are installed, and the steel bars are penetrated through the hole in the end box chamber. Then pour the square frame-shaped tower wall concrete inside and outside the end chamber, make the steel anchor box and the concrete tower wall 1 be connected as a whole, and the perforations on each steel plate are poured into concrete to form perforated plate connectors.

[0046] In order to avoid stress concentration near the end plate of the anchor box, in the design, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com