Composite rubber particle pad for shock absorbing and noise reduction of track and manufacturing method and application of composite rubber particle pad

A technology of compounding rubber and rubber particles is applied in the field of shock absorption and noise reduction layer pads, which can solve the problems of short life, high cost, long time consumption, etc., and achieve the effects of outstanding substantive characteristics, good structural durability and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention will be further described.

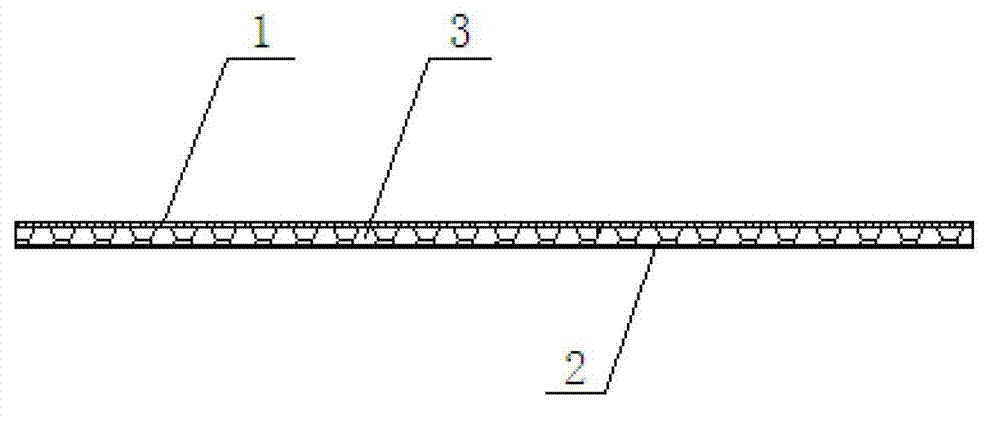

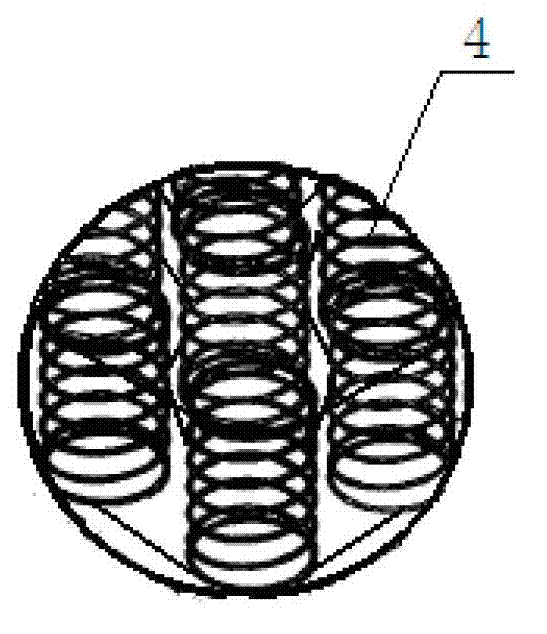

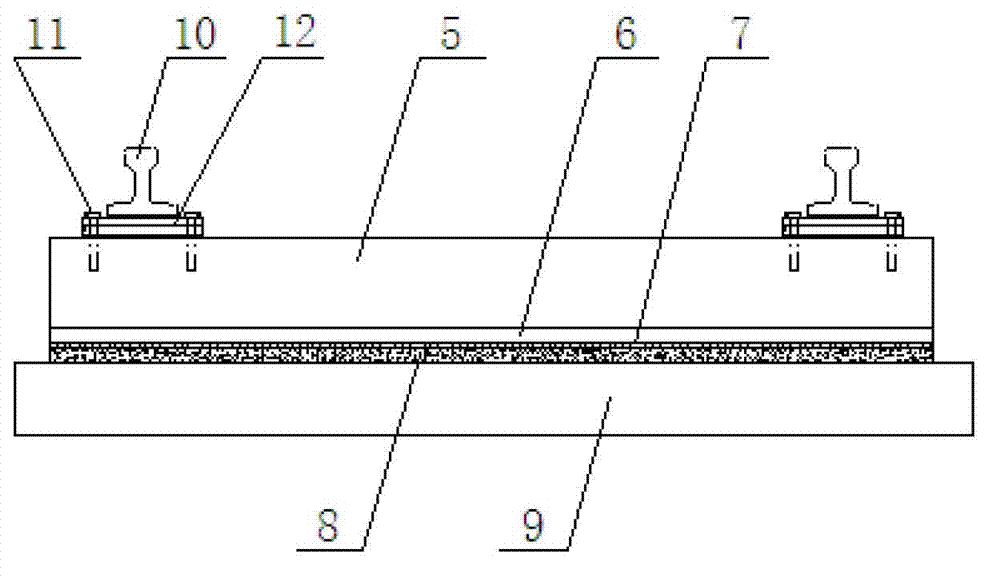

[0013] Such as figure 1 Shown is the schematic diagram of the structure of the composite rubber particle pad of this scheme. The track shock-absorbing and noise-reducing composite rubber particle pad includes a surface non-woven fabric layer 1, a bottom surface non-woven fabric layer 2 and a composite rubber particle layer 3. The composite rubber particle layer 3 is arranged between the surface non-woven fabric layer 1 and the bottom surface non-woven fabric layer 2, and the surface non-woven fabric layer 1, the bottom surface non-woven fabric layer 2 and the composite rubber particle layer 3 are closely combined to form a composite rubber particle pad as a whole. Composite rubber granule layer 3 includes a mixture of 2 parts of rubber granules obtained from crushed waste automobile tires and 1 part of polyurethane adhesive. The diameter of the rubber granules is not grea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com