High-anticorrosion composite Portland cement and production method thereof

A composite silicate and high-resistance technology, which is applied in the field of Portland cement, can solve the problems of low design service life of marine structures, poor corrosion resistance of ordinary cement concrete, and affecting the durability of marine structures. Small ion mobility coefficient, high sulfate corrosion resistance coefficient, and the effect of avoiding loss of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

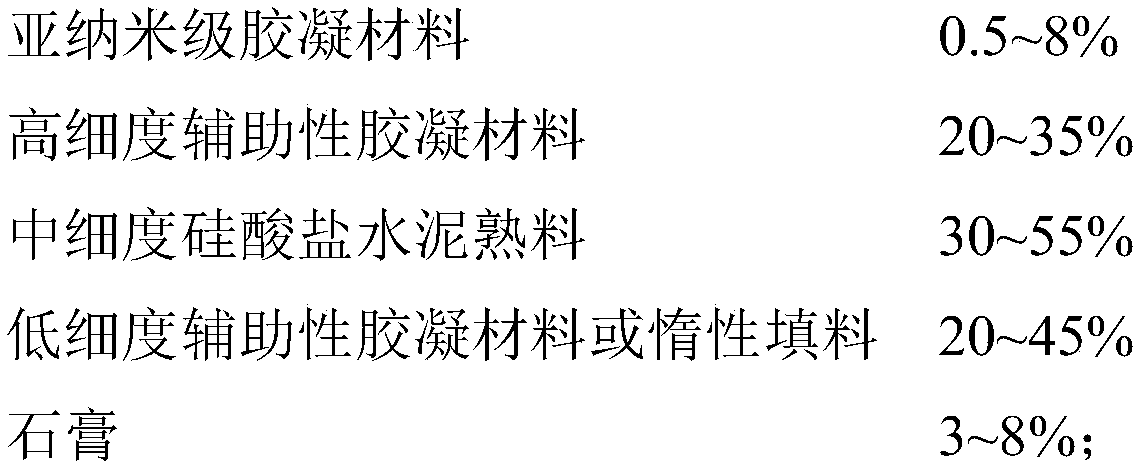

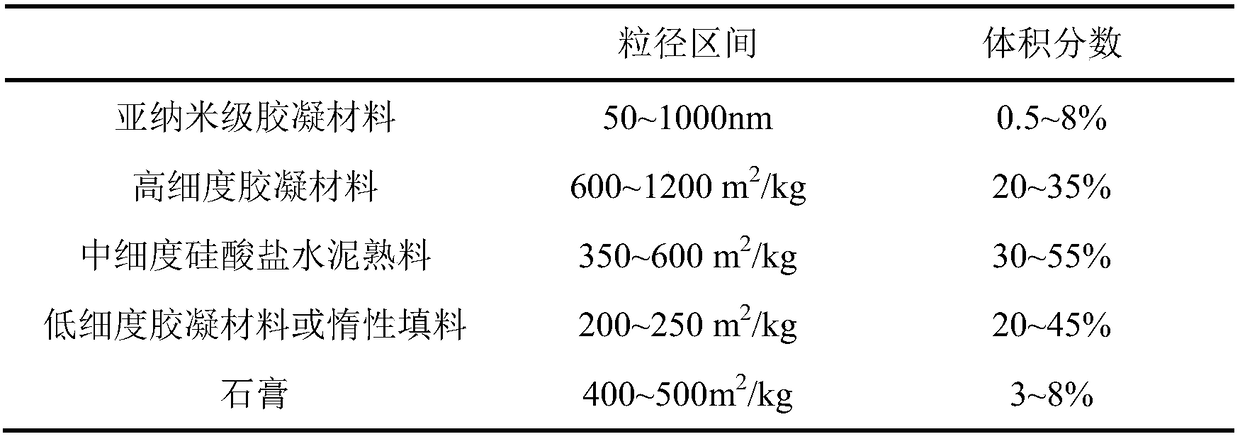

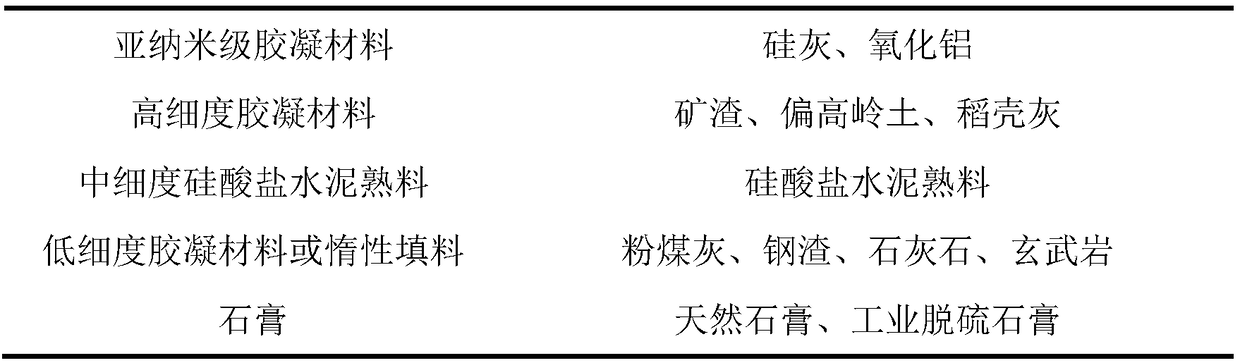

Method used

Image

Examples

Embodiment 1

[0034] The high anti-corrosion composite Portland cement in this example is mainly composed of silica fume, slag, cement clinker, fly ash and gypsum; the volume content of each component, the particle size or specific surface area of each component and the The performance tests of the prepared high-corrosion composite Portland cement are shown in Table 3.

[0035] Table 3 Proportion and properties of a high-corrosion composite Portland cement

[0036]

Embodiment 2

[0038] The high anti-corrosion composite Portland cement in this example is mainly composed of silica fume, metakaolin, slag, cement clinker, fly ash and gypsum; the volume content of each component, the particle size or specific surface area of each component and The performance test of the high anti-corrosion composite Portland cement prepared in this example is shown in Table 4.

[0039] Table 4 Proportion and properties of a high-corrosion composite Portland cement

[0040]

Embodiment 3

[0042]The high anti-corrosion composite Portland cement in this example is mainly composed of silica fume, slag, cement clinker, steel slag and gypsum; the volume content of each component, the particle size or specific surface area of each component, and the The performance tests of the high-corrosion composite Portland cement are shown in Table 5.

[0043] Table 5 Proportion and properties of a high-corrosion composite Portland cement

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com