Prestressed concrete constructing process for curved shape memory alloy tendon

A technology of memory alloy and construction technology, which is applied in the direction of manufacturing tools, ceramic molding machines, construction, etc., can solve the problems of multiple processes, cumbersome operations, and high investment costs, and achieve the goals of expanding the application range, simple construction technology, and reducing investment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the drawings and specific embodiments.

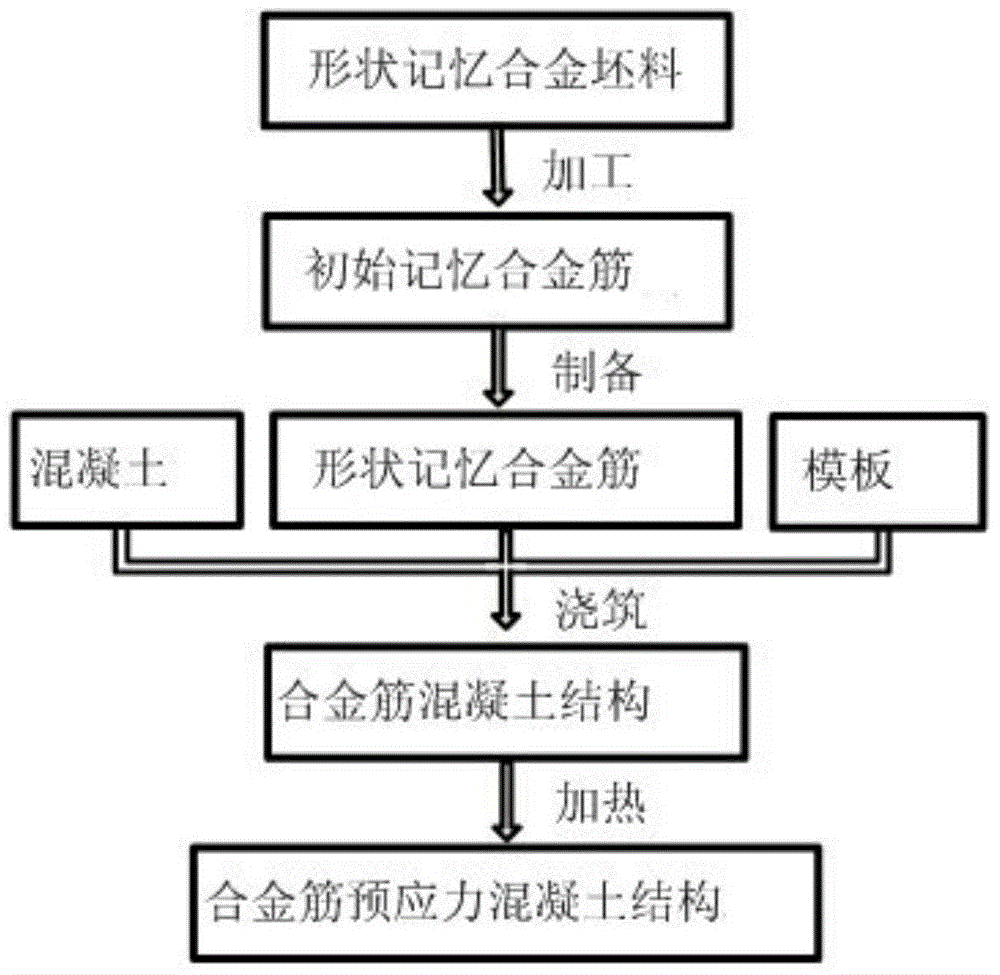

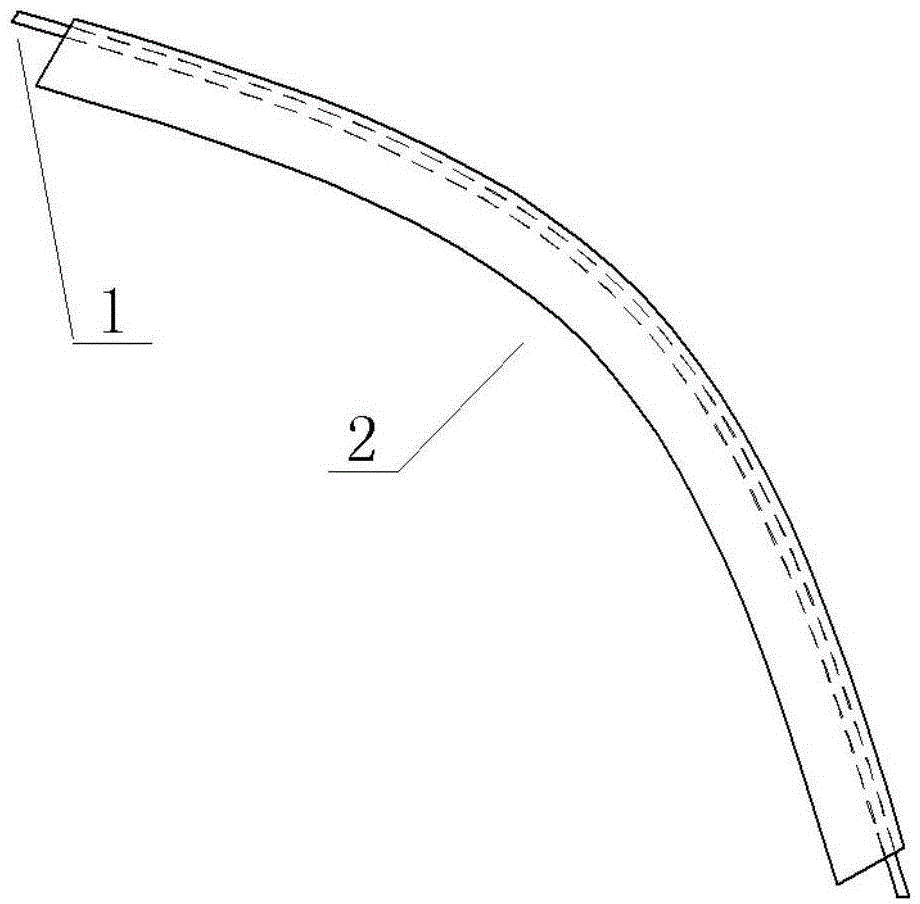

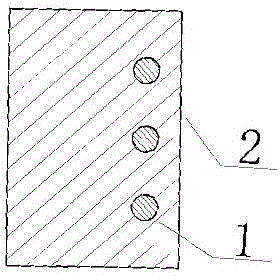

[0027] Such as Figure 1 to Figure 9 As shown, a curvilinear shape memory alloy tendon prestressed concrete construction process, the specific steps are: first, a number of curved shape memory alloy tendons 3 are embedded and arranged in the curved formwork 4 along the length of the concrete 2, and Make the two ends of the shape memory alloy ribs 3 pass through and extend out the form 4 respectively; then pour the concrete 2 into the form 4 to be integrated with the shape memory alloy ribs 3; when the strength of the concrete 2 reaches more than 75%, use The shape memory alloy ribs 3 are heated in batches or one by one by the electrothermal method. After the shape memory alloy ribs 3 are gradually raised to a specified temperature, the shape memory alloy ribs 3 will automatically undergo a martensite reverse transformation transformation, and the The one-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com