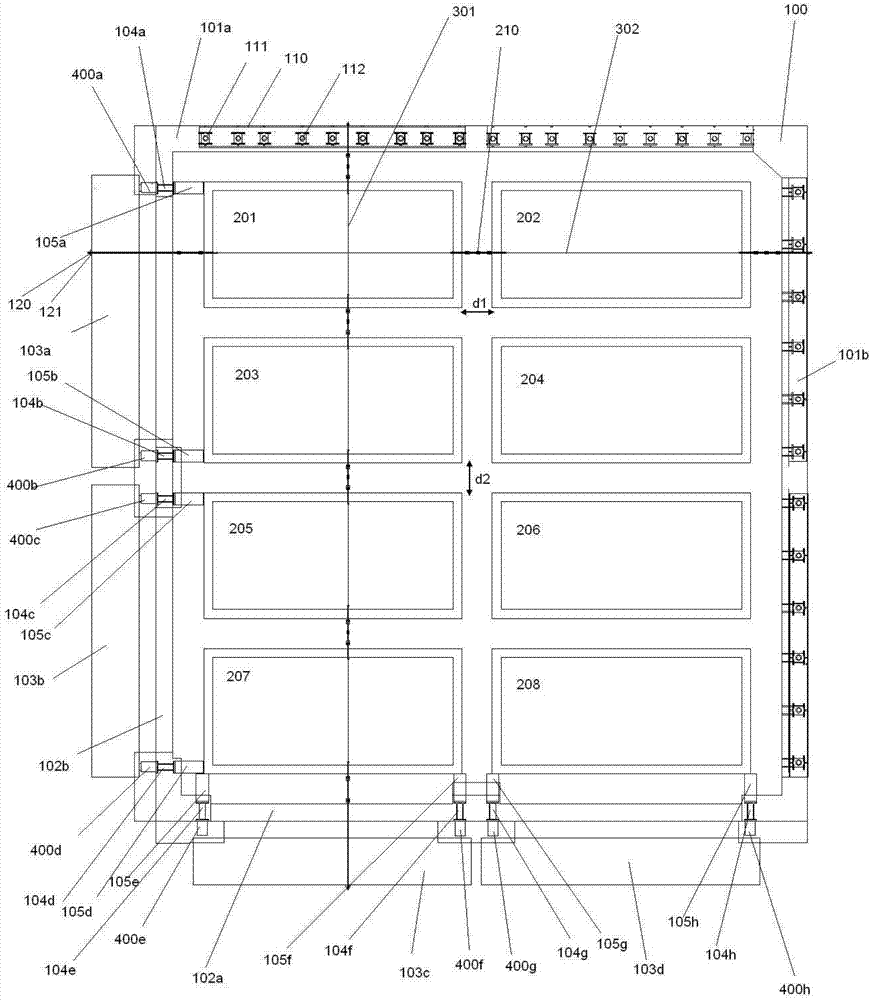

Two-way pre-tensioned prestressed concrete track plate and production method thereof

A production method and technology of track slabs, which are applied in the field of rail transit to achieve the effect of overcoming corrosion of steel bars and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

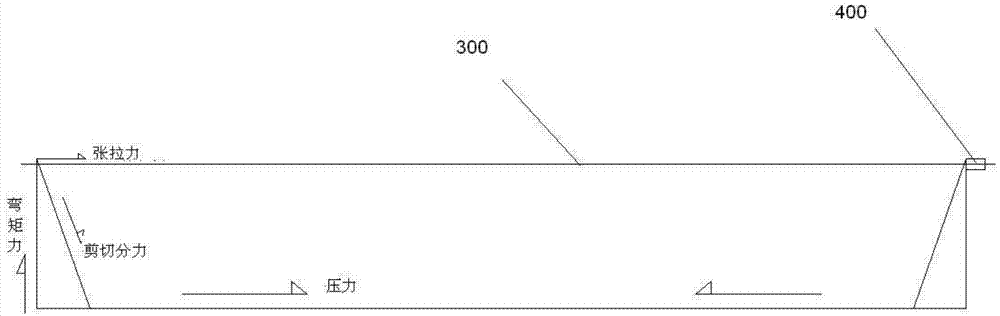

Method used

Image

Examples

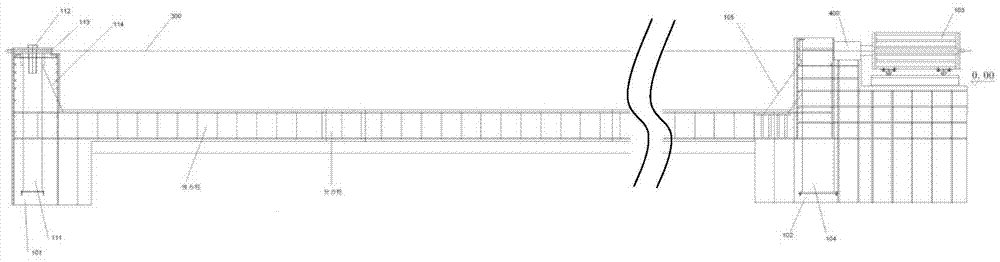

example 1

[0080] According to the principle of tension force, the rectangular tension pit structure is made into a semi-horizontal structure, that is, one part is on the ground and the other part is underground, so that the installation and operation of steel bars are easier and the occupied area is smaller.

[0081] Purchasing initial tensioning equipment and final tensioning equipment according to technical requirements

[0082] According to the technical requirements, the movable end tension steel beams are produced.

[0083] Purchase temperature control equipment according to technical requirements.

[0084] The specific production process is as follows:

[0085] Step 1. Put the prepared steel skeleton and prestressed steel bars into the model together, and test its insulation performance to be greater than 2 megohms;

[0086] Step 2, connect the prestressed steel bar with the connecting rod, and adjust the position of the connecting rod in the model before the initial tension;

[...

example 2

[0106] in accordance with figure 1 The principle is to make the rectangular tension pit structure into a fully horizontal structure, that is, the structures are all below the ground, so that the appearance is relatively neat, and the concrete pouring machine can be installed with a mobile distribution machine.

[0107] According to technical requirements, the steel beam at the movable end can be made into a push structure or a pull structure, and the rest of the process and specific precautions are the same as Example 1.

example 3

[0109] in accordance with figure 1 The principle is to make the rectangular tension pit structure into an all-steel structure, so that the tension structure can be relocated, which is convenient for repeated use. The rest of the process and specific precautions are the same as in Example 1 or Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com