A prefabricated double-layer exterior wall panel and its installation structure and horizontal and vertical waterproof structure

A technology of waterproof structure and installation structure, applied in the direction of walls, building components, building structures, etc., can solve the problems of poor building energy-saving performance, low construction environmental protection, slow construction speed, etc., to avoid buckling deformation and reduce construction waste. The effect of production and construction speed is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

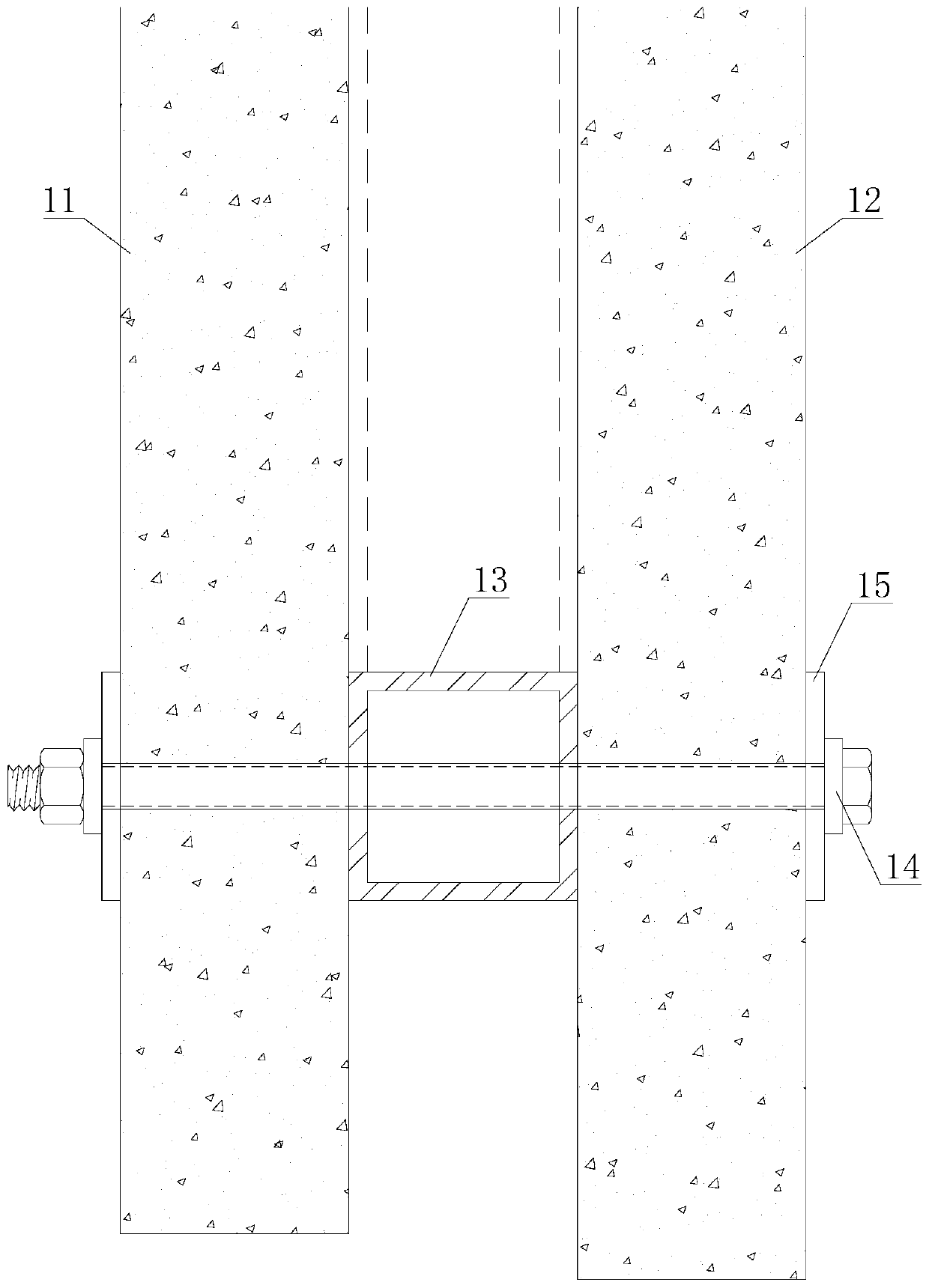

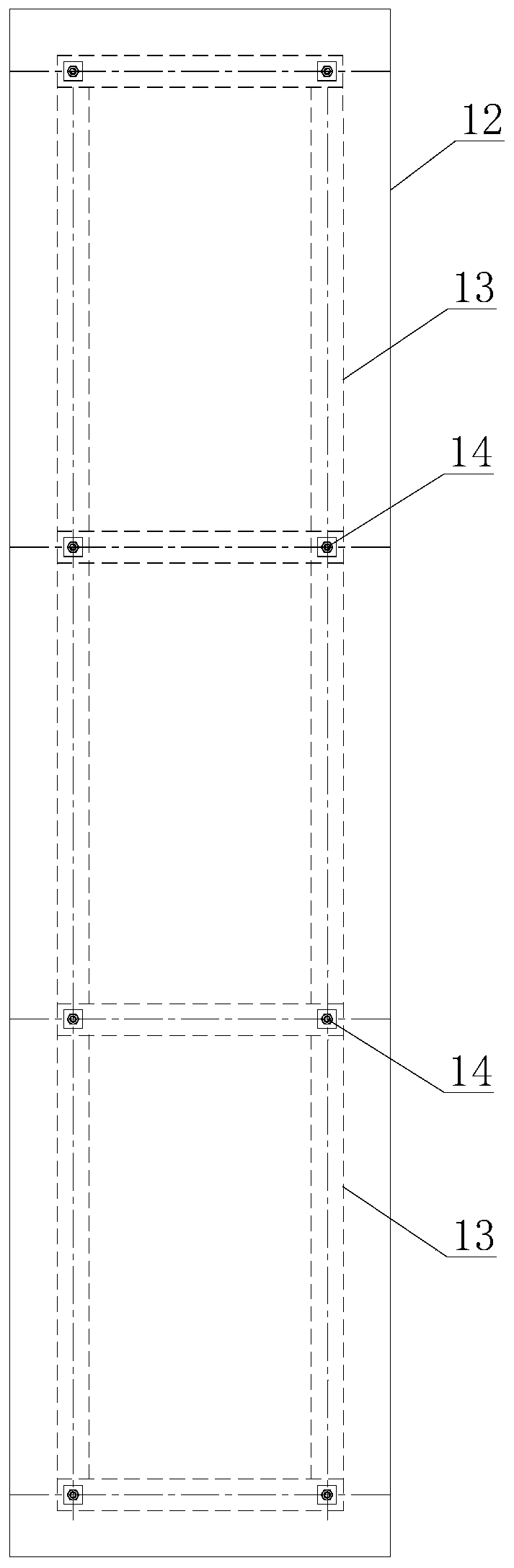

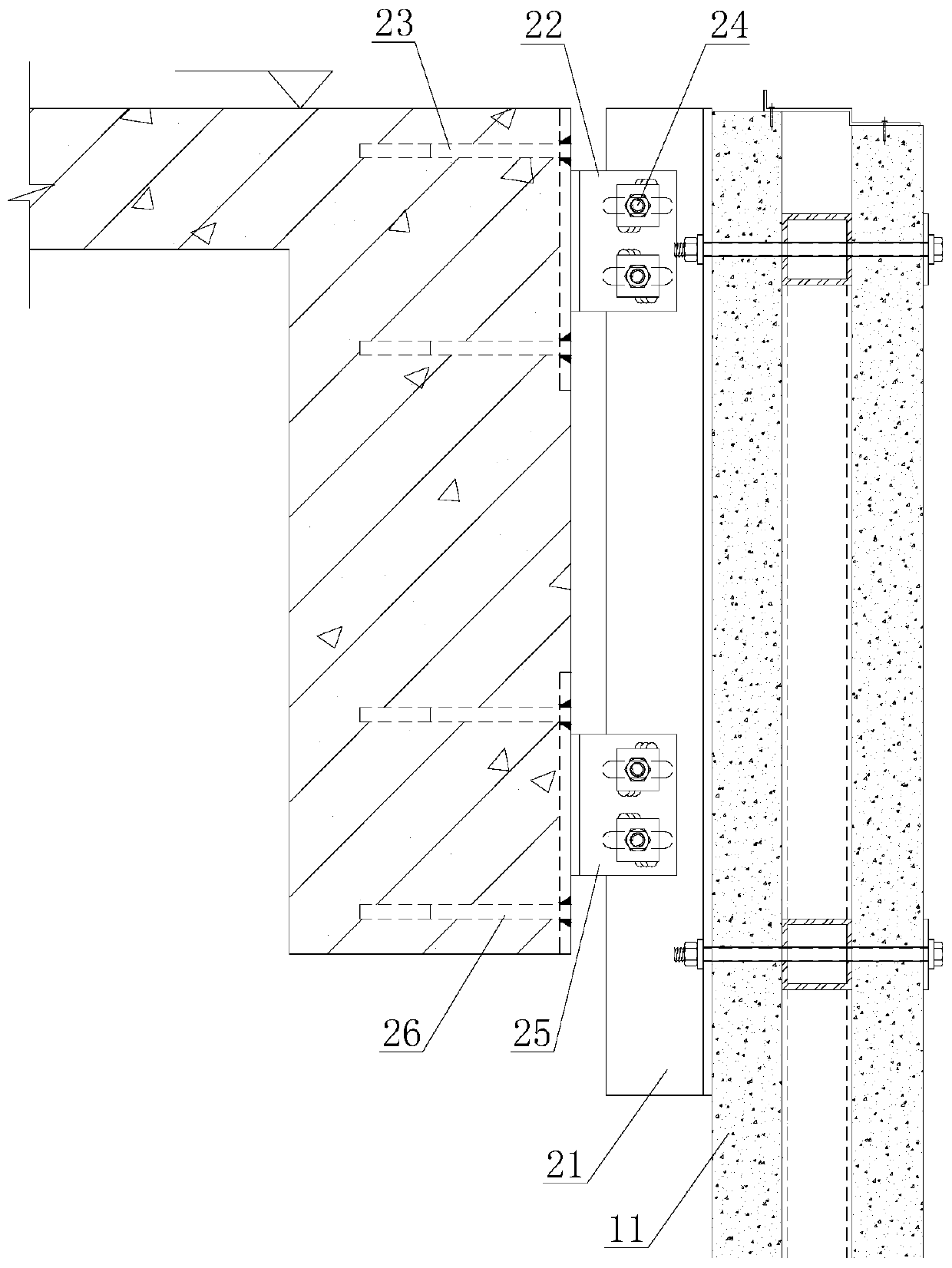

[0040] Please refer to Figure 4 and Figure 5 As shown, the present invention further provides a horizontal waterproof structure of an assembled double-layer exterior wall panel. The horizontal waterproof structure is horizontally waterproof according to the aforementioned assembled double-layer exterior wall panel. For the waterproofing of the horizontal joints of the two-layer exterior wall panels, since the height difference between the inner and outer composite wall panels in the above-mentioned prefabricated double-layer exterior wall panels is not less than 10mm, the waterproofing of the horizontal joints here is mainly handled by structural waterproofing. The waterproof structure includes an upper galvanized iron flap 31 and a lower galvanized iron flap 32. The upper galvanized iron flap 31 and the lower galvanized iron flap 32 include an integrally formed stepped galvanized iron flap 311 and a combined iron sheet 312. The upper galvanized iron flap 31 and the combine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com