Low temperature polycrystalline silicon thin film transistor and manufacturing method therefor

A technology of thin-film transistors and low-temperature polysilicon, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., and can solve problems such as small contact area, large contact resistance, and polysilicon film loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

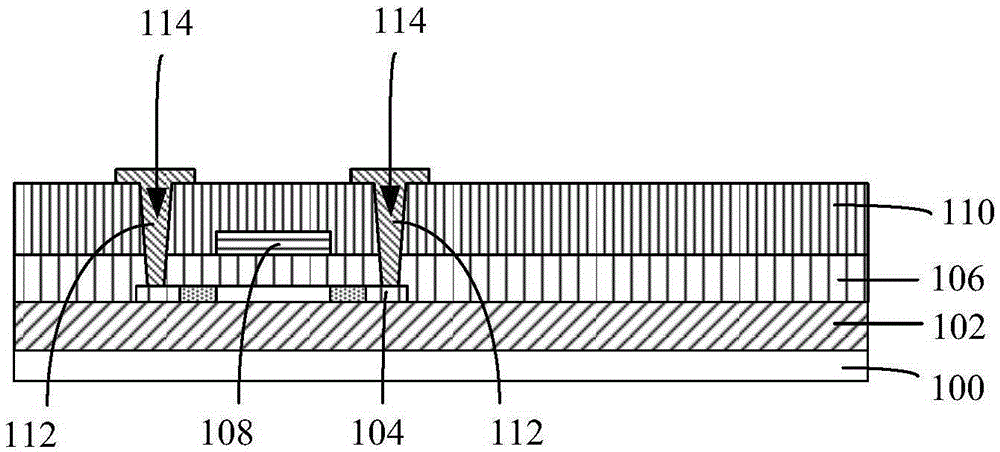

[0030] The description of the present invention provides different examples to illustrate the technical features of different implementations of the present invention. The configuration of each component in the embodiment is for clearly illustrating the content disclosed in the present invention, and is not intended to limit the present invention. In different drawings, the same reference symbols refer to the same or similar components.

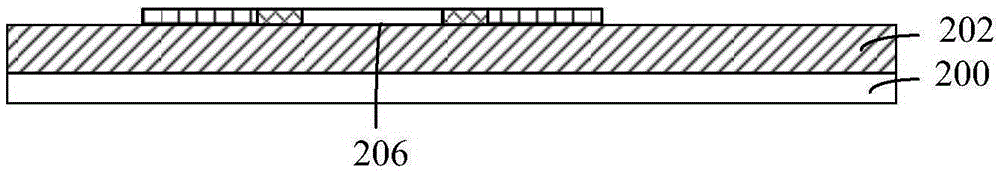

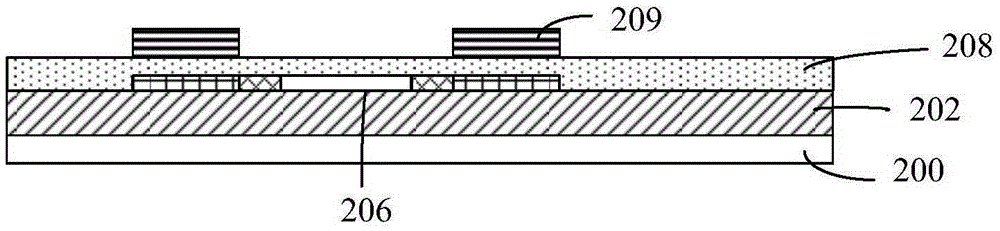

[0031] refer to Figure 2-8 , Figure 2-8 It is a schematic cross-sectional view of the manufacturing process steps of a low-temperature polysilicon thin film transistor according to an embodiment of the present invention. Such as figure 2 As shown, a substrate 200 is provided. In one embodiment, the substrate 200 is, for example, a glass substrate, a quartz substrate, a stainless steel substrate or a plastic substrate.

[0032] Such as figure 2 As shown, a buffer layer 202 is formed on the substrate 200 . In one embodiment, the buff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com