Graphene-containing electrochemical device

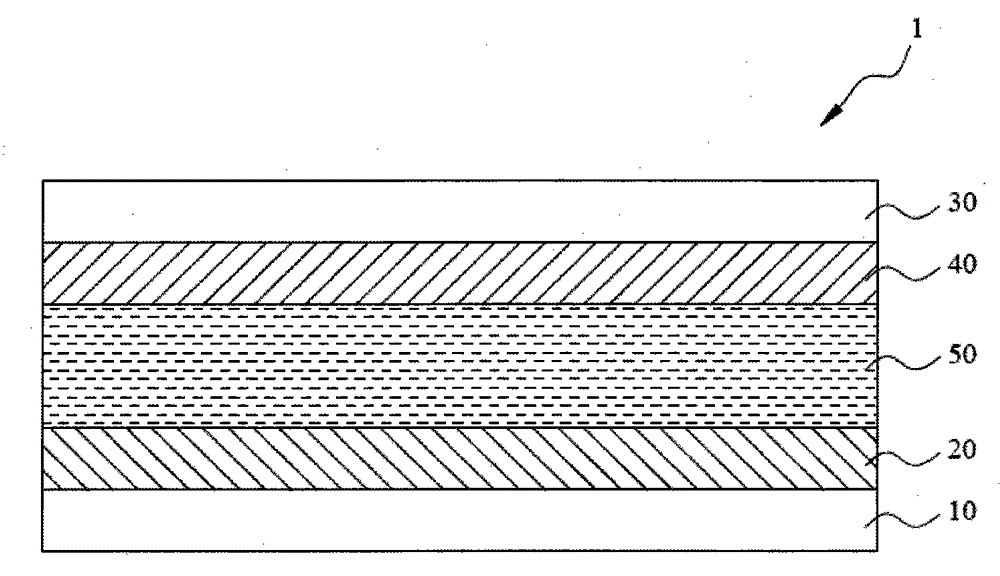

A device structure and graphene technology, applied in structural parts, circuits, electrical components, etc., can solve the problems of poor conductivity and compatibility of positive and negative materials, affecting the performance of electrochemical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

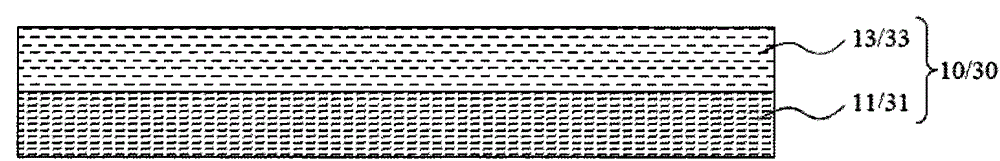

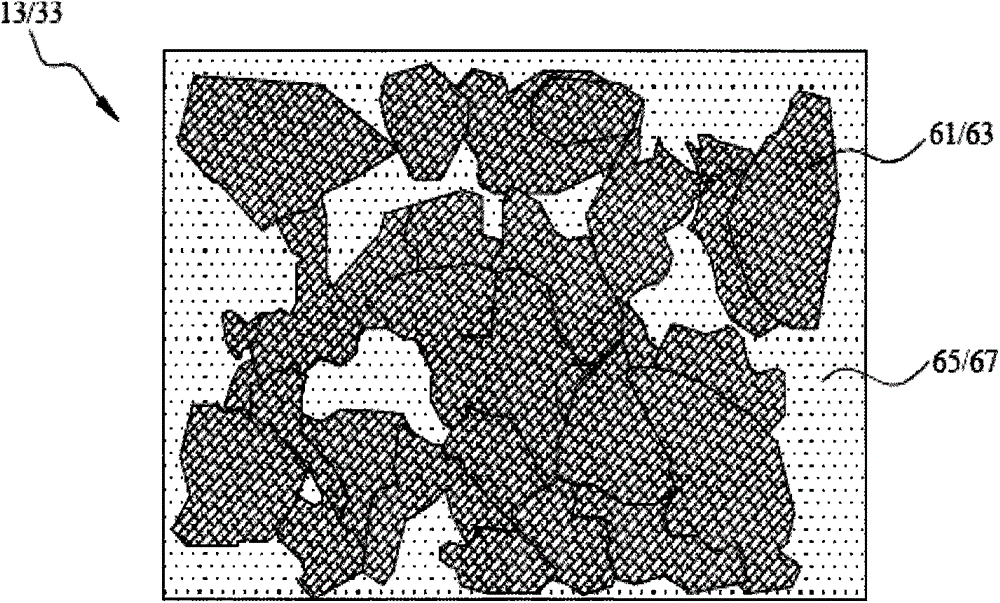

[0042] Put the graphene sheet into N-methylpyrrolidone (NMP) solvent, then add polyvinylidene fluoride (PVDF) as a polymer binder, and ball mill the prepared slurry for several hours to make a graphene slurry , and then spray the graphene slurry on the metal aluminum foil substrate, and dry it to fully volatilize the N-methylpyrrolidone (NMP) solvent to form the positive / negative current collection layer. Next, 80wt% activated carbon positive electrode active material, 10wt% graphene powder and 10wt% polymer binder are added in proportion to N-methylpyrrolidone solvent to prepare slurry, and then the materials are uniformly mixed by ball milling. Form the slurry of its positive electrode active material; add the negative electrode active material of 80wt% activated carbon, 10wt% graphene powder and 10wt% polymer binder in proportion to the preparation slurry in N-methylpyrrolidone solvent, and then ball mill The method is to mix the materials uniformly to form the slurry of th...

Embodiment 2

[0044] Put the graphene sheet into N-methylpyrrolidone (NMP) solvent, then add polyvinylidene fluoride (PVDF) as a polymer binder, and ball mill the prepared slurry for several hours to make a graphene slurry , and then spray the graphene slurry on the metal aluminum foil substrate, and dry it to fully volatilize the N-methylpyrrolidone (NMP) solvent to form the positive / negative current collection layer. Then, 80wt% activated carbon positive electrode active material, 10wt% conductive graphite, and 10wt% polymer binder were added in proportion to N-methylpyrrolidone solvent with 50wt% graphene to prepare slurry, and then ball milled to make each The materials are uniformly mixed to form a slurry of its positive active material; the negative active material of 80wt% activated carbon, 10wt% conductive graphite and 10wt% polymer binder are added in proportion to N-methylpyrrolidone solvent with 50wt% graphene The slurry is prepared in the medium, and then the materials are unifo...

Embodiment 3

[0046] Put the graphene sheet into N-methylpyrrolidone (NMP) solvent, then add polyvinylidene fluoride (PVDF) as a polymer binder, and ball mill the prepared slurry for several hours to make a graphene slurry , and then spray the graphene slurry on the metal aluminum foil substrate, and dry it to fully volatilize the N-methylpyrrolidone (NMP) solvent to form the positive / negative current collection layer. Then, 85wt% lithium iron phosphate with graphene, 7wt% conductive graphite, 3.75wt% binder and 4.25wt% N-methylpyrrolidone were mixed uniformly by ball milling to prepare positive electrode active material slurry , prepared with 80wt% activated carbon, 10wt% graphene, 10wt% binder and N-methylpyrrolidone, and then mixed the materials uniformly by ball milling to form negative active material slurry; / Negative electrode current collection layer, and placed in a vacuum oven to dry it. The positive / negative electrode current collection layers formed with the positive / negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com