Metal-isolator-metal transformer and its manufacturing method

A manufacturing method and insulator technology, which is applied in the direction of inductance/transformer/magnet manufacturing, fixed transformer or mutual inductance, transformer/inductor coil/winding/connection, etc., which can solve the problems of increased cost, low transformer coefficient, and large radio frequency circuit area and other issues, to achieve the effect of improving component performance, saving process costs, and improving coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The existing transformer has problems such as large area and large space between coils, which affect the process cost and device performance. Therefore, the present invention proposes a metal-insulator-metal transformer and a manufacturing method thereof to solve the above problems.

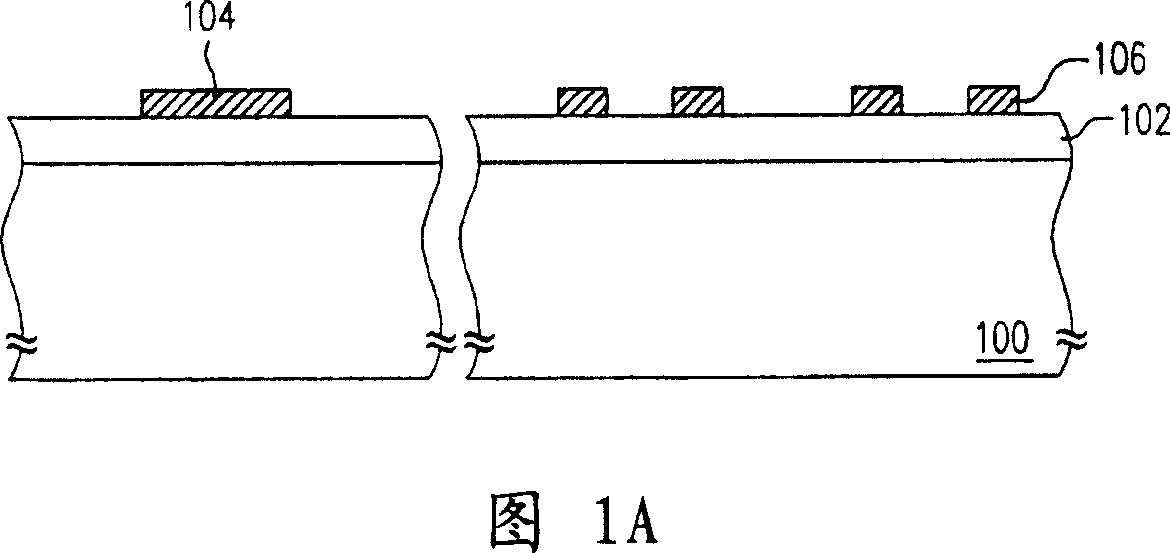

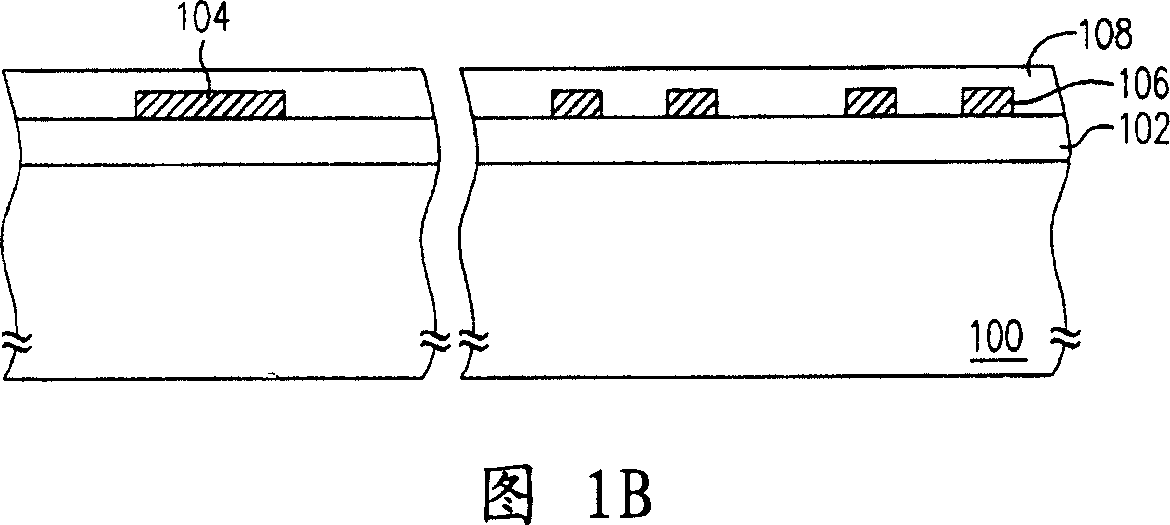

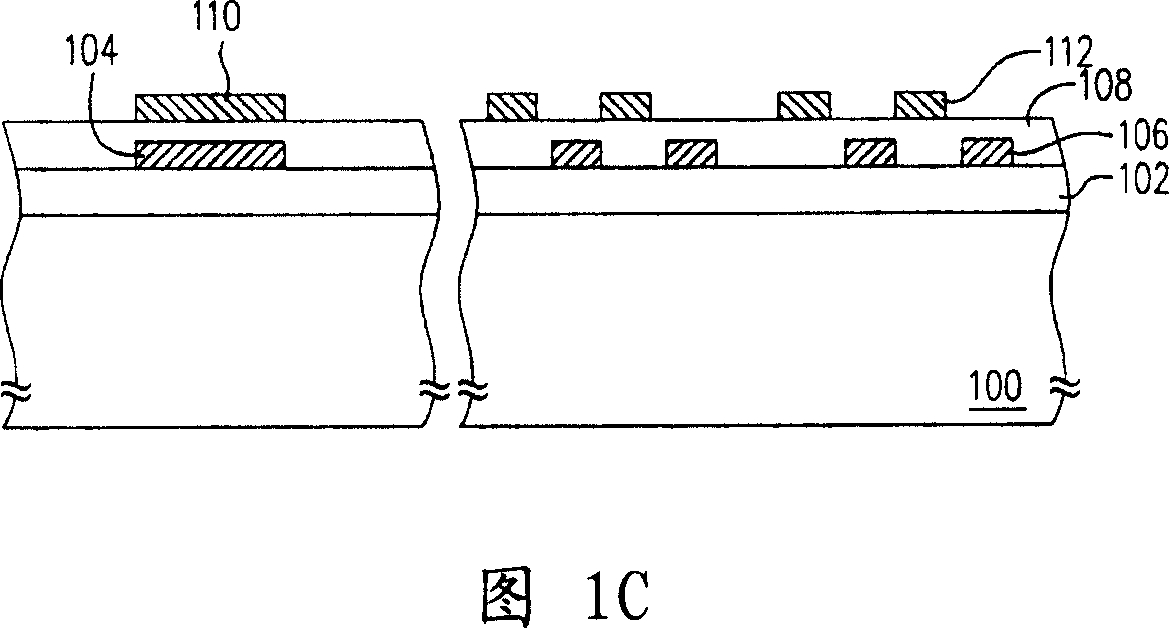

[0039] 1A to 1C are schematic cross-sectional views of a manufacturing method of a metal-insulator-metal transformer according to an embodiment of the present invention.

[0040] First, please refer to FIG. 1A , a substrate 100 is provided, and at least a dielectric layer 102 is formed on the substrate 100 . The material of the dielectric layer 102 is, for example, generally known dielectric materials such as silicon oxide, silicon nitride, and low dielectric constant materials. The method for forming the dielectric layer is, for example, first depositing a layer of dielectric layer ( not shown) on the substrate 100, and then planarized by chemical mechanical polishing (CMP) to form. Tho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com