Formation method of softly-packed lithium ion battery

A technology of lithium-ion batteries and chemical formation methods, applied in the field of lithium-ion batteries, can solve the problems of long production cycle and poor cycle performance of soft-pack lithium-ion batteries, and achieve short production cycle, suitable for large-scale industrial production, and high density and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

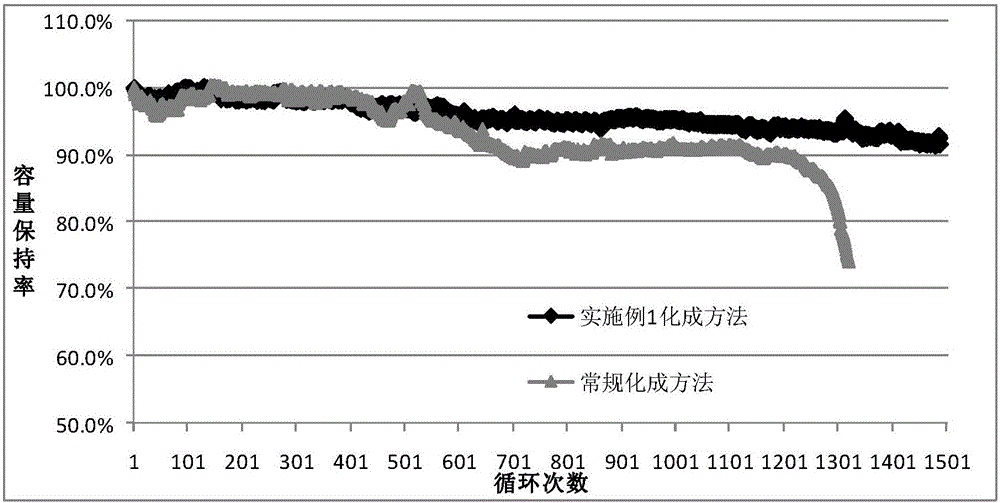

Embodiment 1

[0032] The formation method of the soft pack lithium-ion battery of the present embodiment comprises the following steps:

[0033] 1) Clamp the aged soft-pack lithium-ion battery in the formation fixture of the high-temperature pressurized formation equipment, turn on the pressure switch to increase the pressure between the fixtures to the set value, and ensure the surface of the soft-pack lithium-ion battery on both sides The pressure is 1.5MPa;

[0034] Set the temperature value of the high-temperature pressurized formation equipment to 65°C, turn on the temperature switch, and raise the temperature of the soft-pack lithium-ion battery to 65°C;

[0035] 2) Formation: first use 0.03C current to precharge the soft-pack lithium-ion battery with a small current, the charging time is 30min, and the cut-off voltage is 3.0V; then use 0.5C current to charge with a constant current until the cut-off voltage is 3.6V; Constant current constant voltage charging, to cut-off voltage 4.2V...

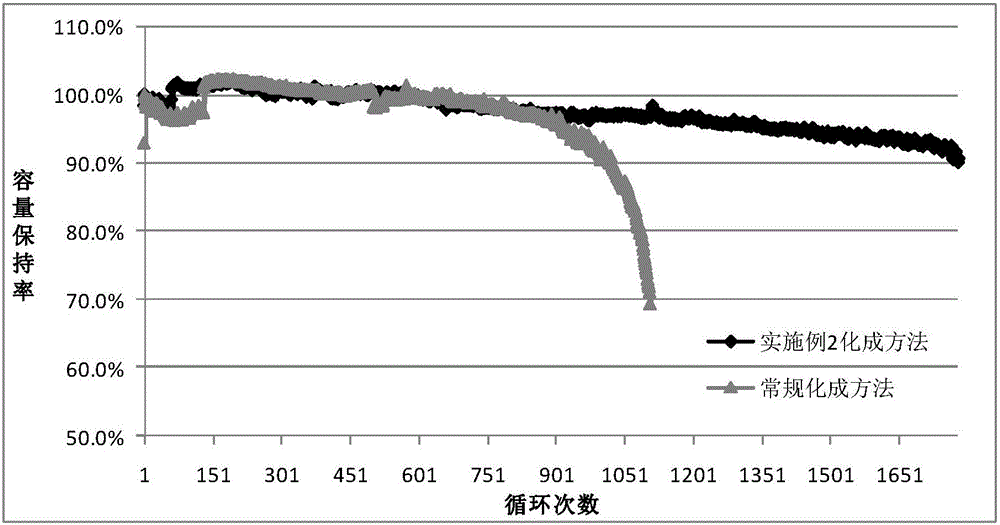

Embodiment 2

[0040] The formation method of the soft pack lithium-ion battery of the present embodiment comprises the following steps:

[0041] 1) Clamp the aged soft-pack lithium-ion battery in the formation fixture of the high-temperature pressurized formation equipment, turn on the pressure switch to increase the pressure between the fixtures to the set value, and ensure the surface of the soft-pack lithium-ion battery on both sides The pressure is 2.9MPa;

[0042] Set the temperature value of the high-temperature pressurized formation equipment to 45°C, turn on the temperature switch, and raise the temperature of the soft-packed lithium-ion battery to 45°C;

[0043]2) Formation: first use 0.02C current to precharge the soft-pack lithium-ion battery with a small current, the charging time is 30min, and the cut-off voltage is 3.0V; then use 0.7C current to charge with a constant current until the cut-off voltage is 3.6V; Constant current constant voltage charging, to cut-off voltage 4.2...

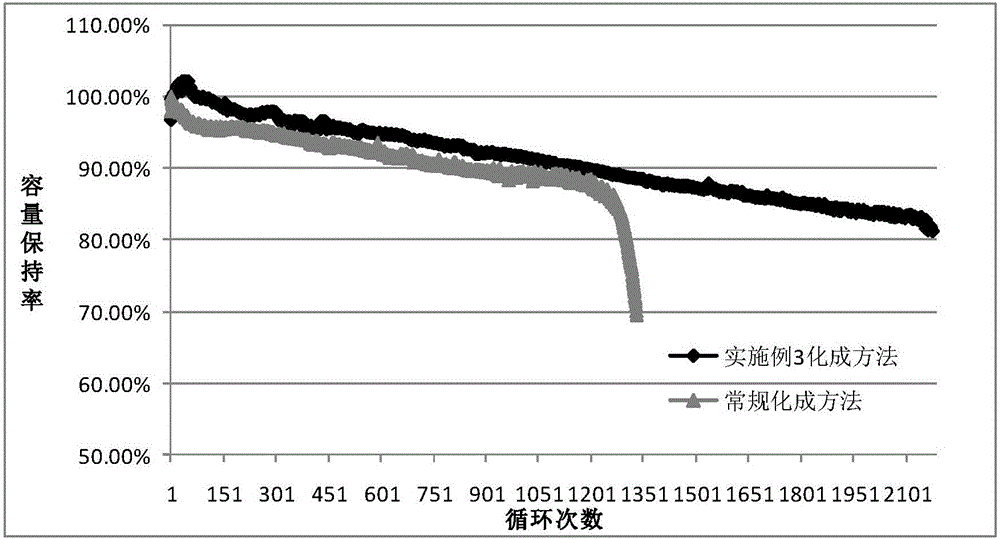

Embodiment 3

[0048] The formation method of the soft pack lithium-ion battery of the present embodiment comprises the following steps:

[0049] 1) Clamp the aged soft-pack lithium-ion battery in the formation fixture of the high-temperature pressurized formation equipment, turn on the pressure switch to increase the pressure between the fixtures to the set value, and ensure the surface of the soft-pack lithium-ion battery on both sides The pressure is 0.5MPa;

[0050] Set the temperature value of the high-temperature pressurized formation equipment to 55°C, turn on the temperature switch, and raise the temperature of the soft-packed lithium-ion battery to 55°C;

[0051] 2) Formation: first use 0.01C current to pre-charge the soft-pack lithium-ion battery with a small current, the charging time is 30min, and the cut-off voltage is 3.0V; then use 0.1C constant current to charge until the cut-off voltage is 3.6V; then use 0.5C current Constant current constant voltage charging, to cut-off vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com