Detachable nozzle and device for manufacturing atomic layer deposited film

A technology of atomic layer deposition and nozzle, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of time-consuming, expensive, and inability to change the size parameters of the air inlet and air outlet, and achieve simplified operation effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] On the silicon wafer, deposit the Al2O3 film, the precursor A is trimethylaluminum, and the precursor B is H20.

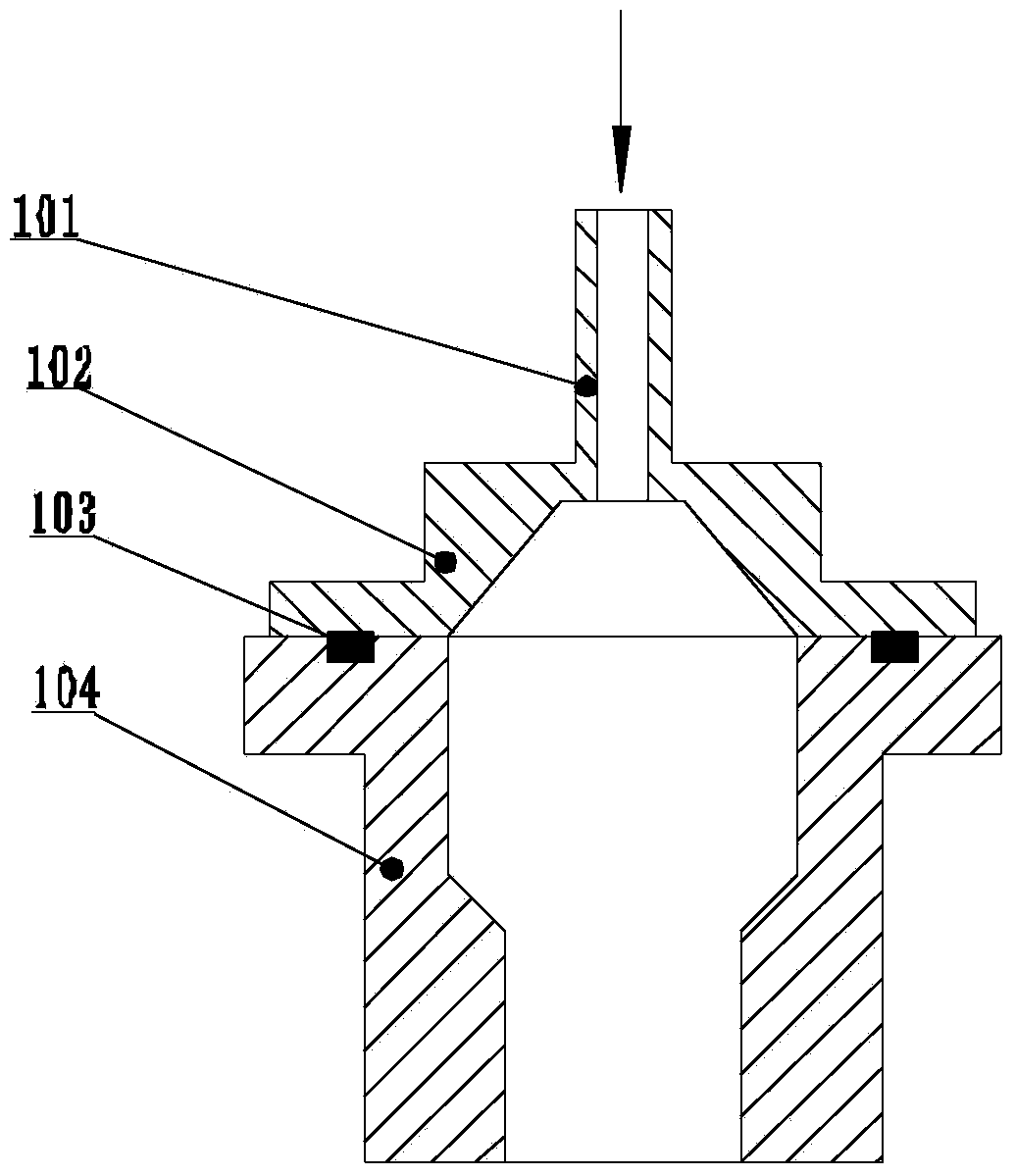

[0041] For the reaction of the precursor, the detachable nozzle provided by the present invention is made of 316L stainless steel. The detachable spray head includes an air intake pipeline, an air inlet and an air outlet.

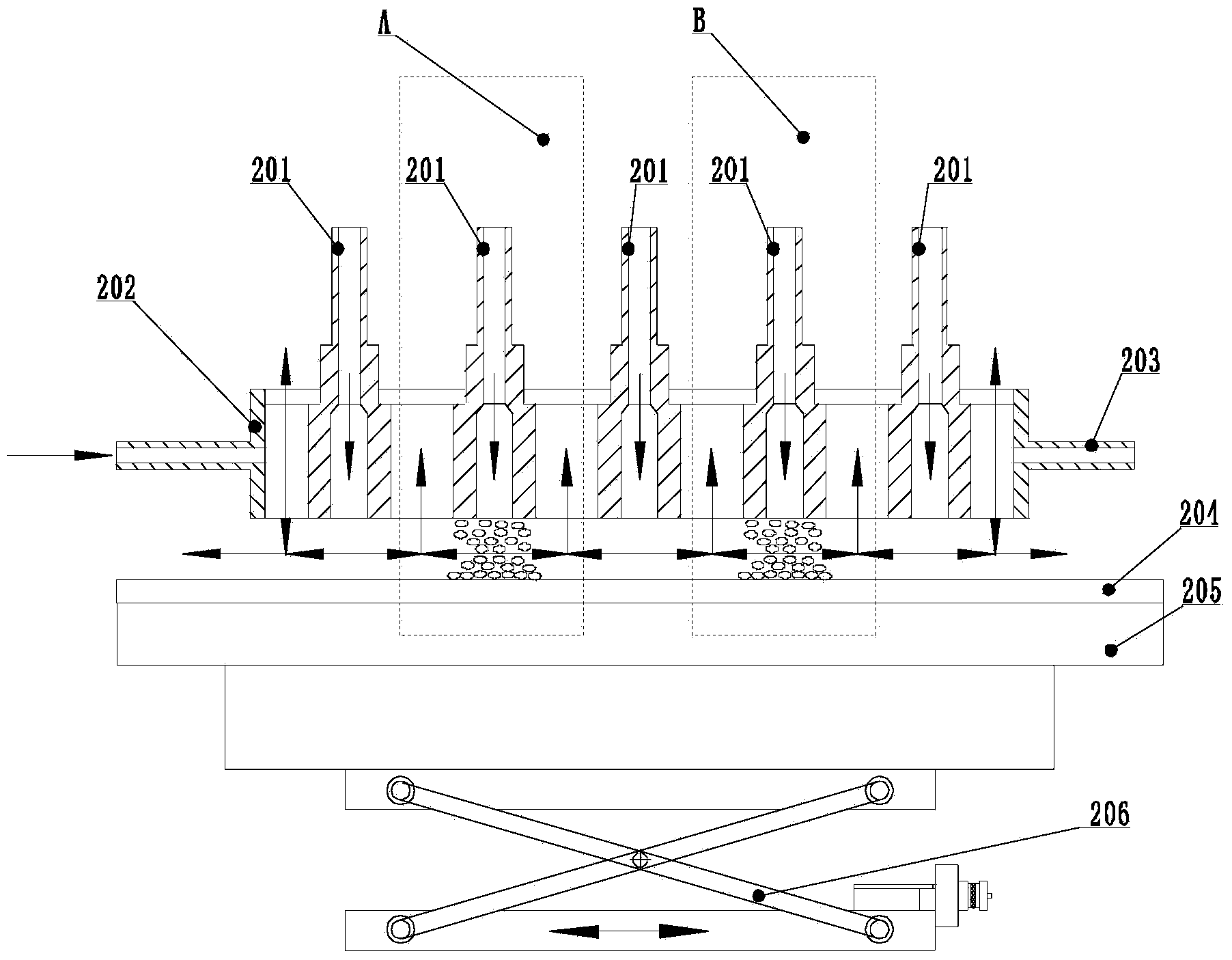

[0042] The air intake pipeline is a 1 / 4 inch swagelok (Swagelok) straight pipe or elbow pipe, and the inside of the air inlet is a trapezoidal cavity with a narrow top and a wide bottom, with an upper width of 6mm, a lower width of 30mm, and a height of 12mm , trapezoid angle 45 degrees. It is convenient for the gas to diffuse faster from the thinner pipeline to the larger structural cavity. The lower end of the inner cavity of the air inlet is rectangular with a size of 30*10mm. A cavity is formed inside the air outlet, the upper half of which has the same size as the lower end of the inner cavity of the air inlet, and the lower half o...

Embodiment 2

[0051] Alternately deposited on silicon wafers 2 o 3 film and TiO 2 film, precursor A is trimethylaluminum, precursor B is H 2 O, precursor C is titanium tetrachloride.

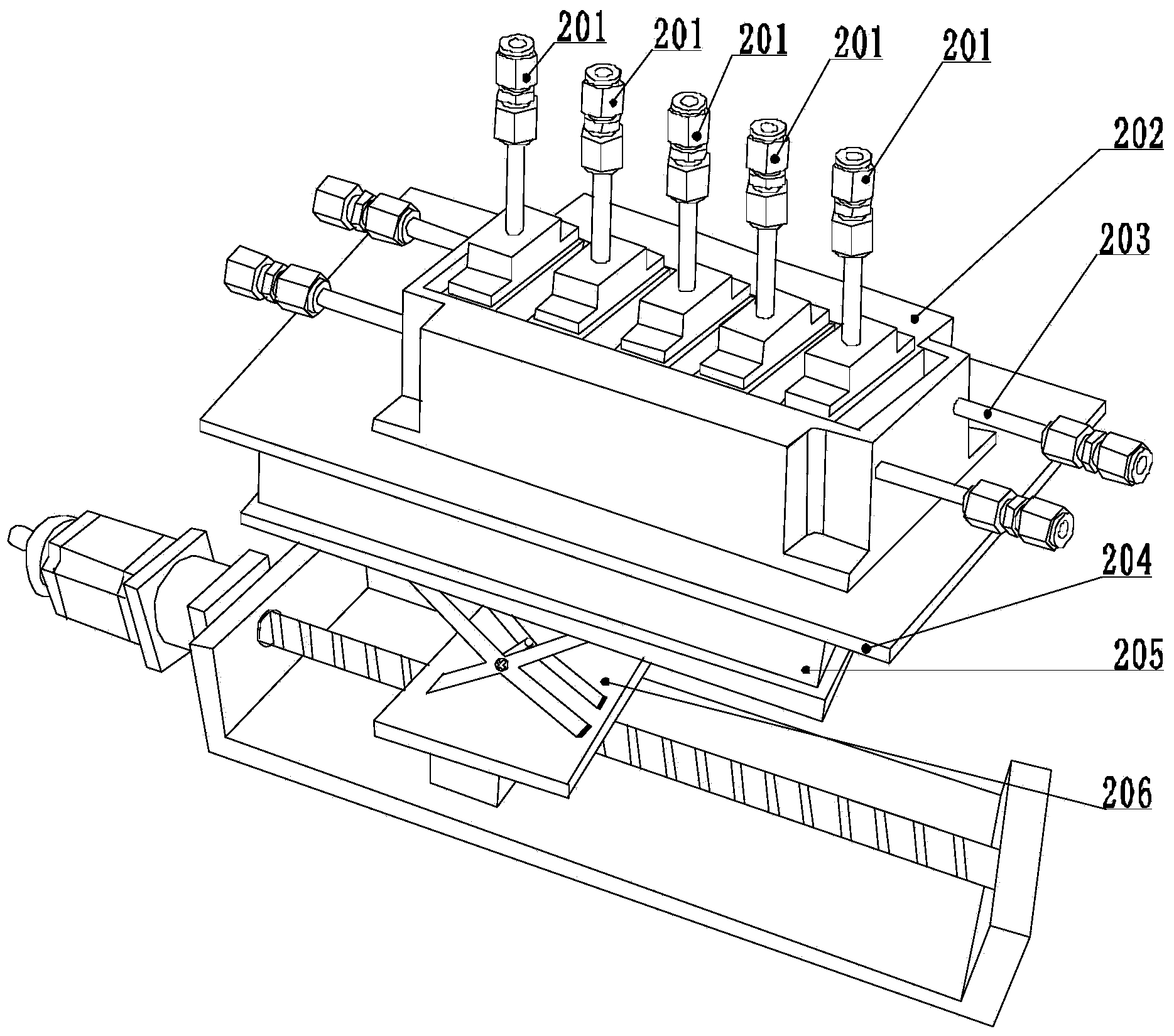

[0052] For the reaction of the precursor, the detachable nozzle provided by the present invention is made of 304 stainless steel. The detachable spray head includes an air intake pipeline, an air inlet and an air outlet.

[0053] The air intake pipe is a 1 / 4 inch swagelok (Swagelok) straight or bent pipe. The inside of the air inlet is a trapezoidal cavity with a narrow top and a wide bottom. The upper width is 6mm, the lower width is 30mm, and the height is 12mm. The included angle of the trapezoid is 45 degrees. It is convenient for the gas to diffuse faster from the thinner pipeline to the larger structural cavity. The lower end of the inner cavity of the air inlet is rectangular with a size of 30*10mm. A cavity is formed inside the air outlet, the upper half of which has the same size as the lower e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com