Non-isothermal creep age forming method for Al-Zn-Mg-Cu series aluminum alloy plate

A technology of creep aging forming and aluminum alloy plates, which is applied in heat treatment equipment, furnaces, heat treatment furnaces, etc., and can solve problems such as difficult to accurately control cooling speed, limit heating and cooling speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

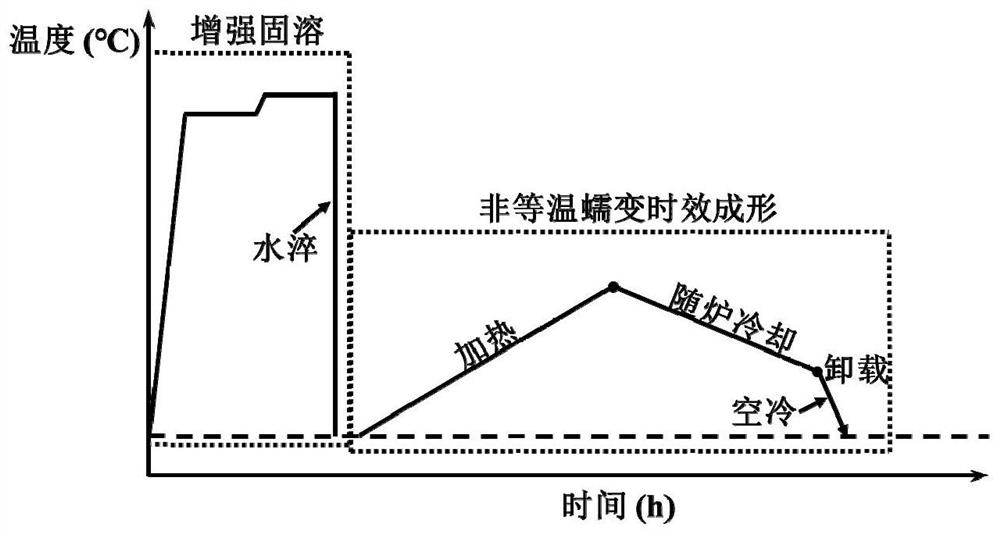

Embodiment 1

[0027] A 2mm thick plate adopts solution treatment, heats it at 470°C for 1h, heats it to 500°C for 1h, and then performs water quenching at room temperature within 5s. The plates were then clamped in a mold with a curvature of 1000 mm for non-isothermal creep aging. The heating rate of non-isothermal creep aging is 20℃ / h, and the maximum aging temperature is 160℃. After heating up to the highest aging temperature, stop heating immediately, and the plate and mold as a whole are cooled to 50°C with the furnace, then taken out and unloaded, and the alloy plate is air-cooled to room temperature.

Embodiment 2

[0029] B 2mm-thick plate adopts solid solution treatment, heats it at 470°C for 1h, heats it to 500°C for 1h, and then performs water quenching at room temperature within 5s. The plates were then clamped in a mold with a curvature of 1000 mm for non-isothermal creep aging. The non-isothermal creep aging heating rate is 20°C / h, and the maximum aging temperature is 180°C. After heating up to the highest aging temperature, stop heating immediately, and the plate and mold as a whole are cooled to 50°C with the furnace, then taken out and unloaded, and the alloy plate is air-cooled to room temperature.

Embodiment 3

[0031]C 2mm thick plate adopts solution treatment, heat at 470°C for 1h, heat to 500°C for 1h, and then water quench at room temperature within 5s. The plates were then clamped in a mold with a curvature of 1000 mm for non-isothermal creep aging. The non-isothermal creep aging heating rate is 20°C / h, and the maximum aging temperature is 200°C. After heating up to the highest aging temperature, stop heating immediately, and the plate and mold as a whole are cooled to 50°C with the furnace, then taken out and unloaded, and the alloy plate is air-cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com