Method for preparing alkali type copper molybdate microsphere having surface nano-whisker structure

A technology of nano-whiskers and copper molybdate, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of unrealized industrial production, and achieve convenient and simple product processing and high control The effect of stability and product shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Weigh 0.0203g Na respectively 2 MoO 4 .2H 2 O was placed in a 20ml reaction flask labeled A, and then weighed 0.0261g Cu(NO 3 ) 2 .2H 2 O was placed in a 20ml reaction bottle labeled B, and 5ml of deionized water was added to sonicate until it dissolved into a transparent solution.

[0040] Step 2: Add the solution in B to A dropwise, and stir magnetically for 50 minutes at room temperature.

[0041] Step 3: Use NaOH and HNO 3 Adjust the pH of the mixed solution to 6, and sonicate for 5 minutes.

[0042] Step 4: Transfer the above mixed solution to a 15ml reaction kettle and keep it warm at 110°C for 12 hours.

[0043] Step 5: Cool naturally to room temperature, and wash the product several times with water and ethanol respectively.

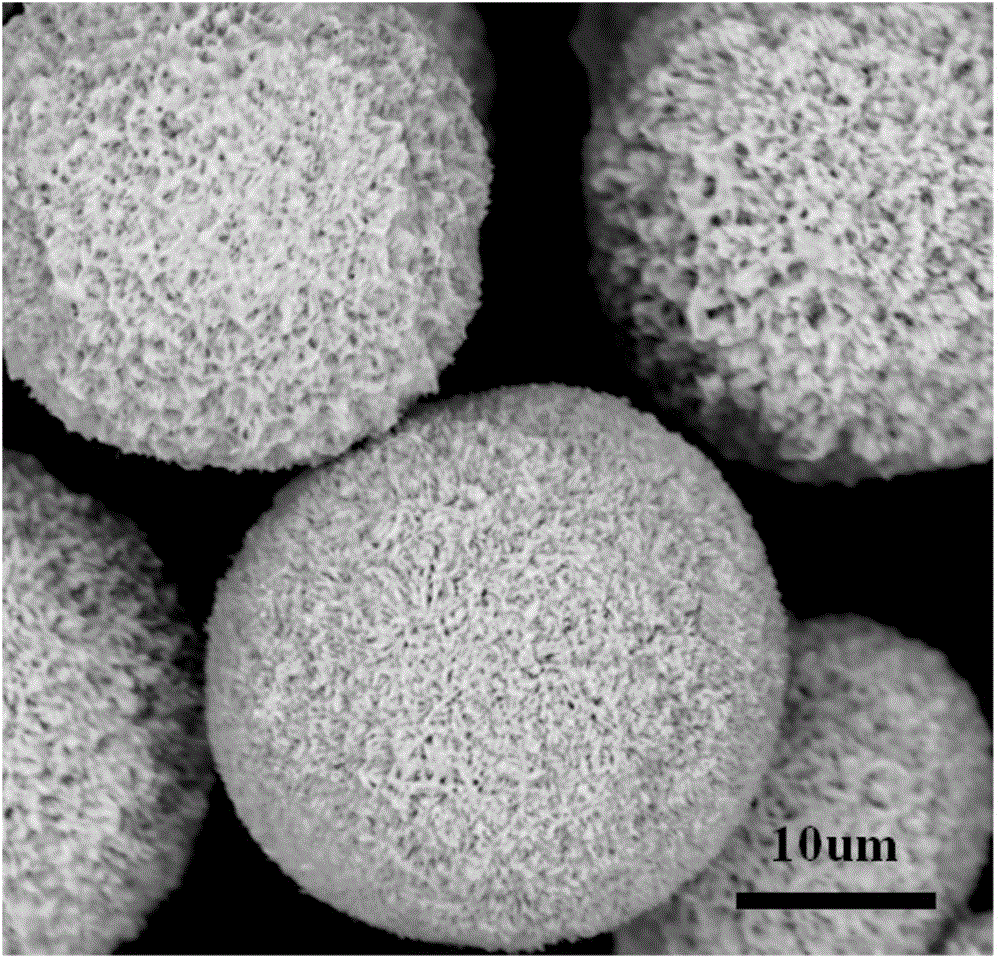

[0044] figure 1 Obtain the SEM photograph of product under the multiple of 10um in the embodiment 1, as can be seen from the figure, the basic copper molybdate microsphere diameter is about 20um, and the nano whisker struc...

Embodiment 2

[0046] Step 1: Weigh 0.0112g Na respectively 2 MoO 4 .2H 2 O is placed in a 20ml reaction bottle labeled A, and then weighed 0.0121g Cu(Ac) 2 .2H 2 O was placed in a 20ml reaction bottle labeled B, and 5ml of deionized water was added to sonicate until it dissolved into a transparent solution.

[0047] Step 2: Add the solution in B to A dropwise, stir magnetically for 50 minutes at room temperature, and sonicate for 5 minutes.

[0048] Step 3: Transfer the above mixed solution to a 15ml reaction kettle and keep it warm at 110°C for 12 hours.

[0049] Step 4: Cool naturally to room temperature, and wash the product several times with water and ethanol respectively.

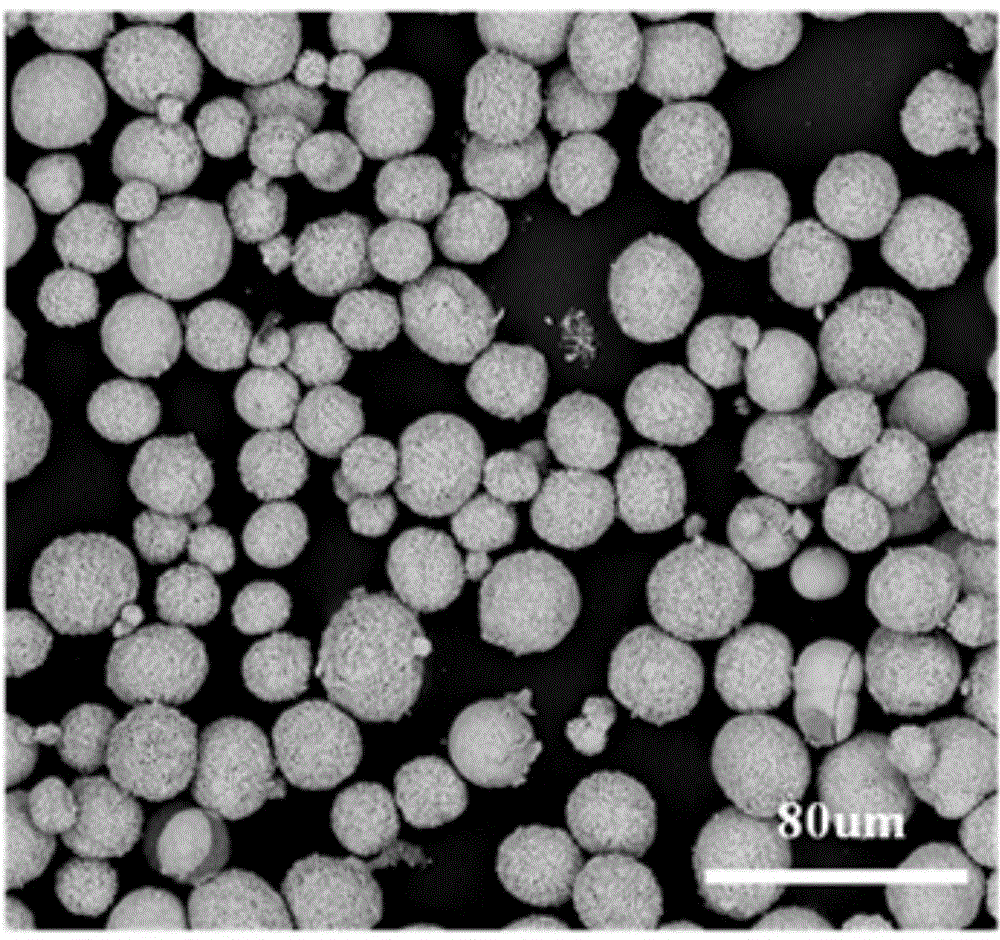

[0050] Figure 8 It is the SEM photo of the product obtained under the multiple of 10um in Example 2. The basic copper molybdate synthesized under this condition is a cocklebur-like structure with a diameter of 30um, and there are many and loose nano whiskers distributed on the surface.

Embodiment 3

[0052] Step 1: Weigh 0.3909g Na respectively 2 MoO 4 .2H 2 O, 0.1648g NaOH is placed in the 20ml reaction flask labeled A, and then weigh 0.0571g Cu(Ac) 2 .2H 2 O was placed in a 20ml reaction bottle labeled B, and 15ml of deionized water was added to it and sonicated until it was dissolved into a transparent solution.

[0053] Step 2: Add 5ml of the solution in B to 5ml of A dropwise, and control the reaction temperature to 35°C with a water bath, and turn on magnetic stirring.

[0054] Step 3: Adjust the pH of the mixture to 6 with acetic acid solution.

[0055] The fourth step: keep warm for three hours, and end the reaction.

[0056] Step 5: After cooling down to room temperature, wash twice with absolute ethanol and deionized water.

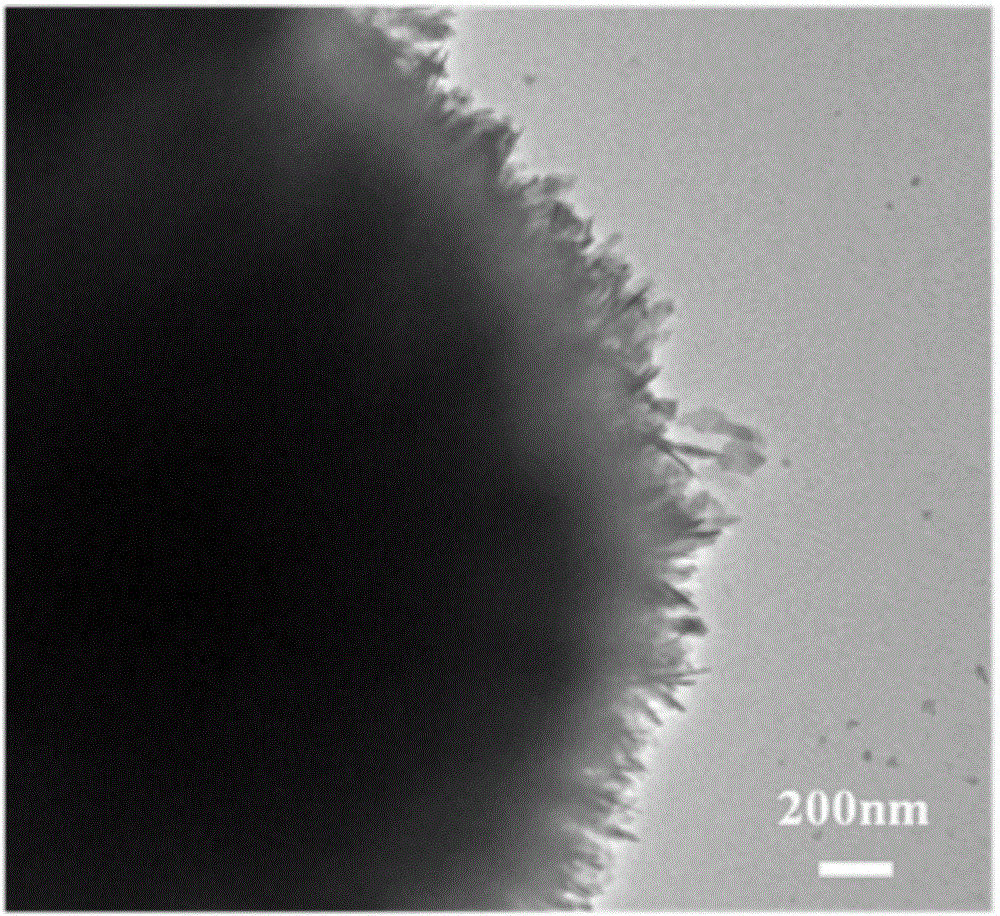

[0057] Figure 9 It is the SEM photograph of the product obtained under the multiple of 1um in embodiment 3. Figure 10 It is the SEM photograph of the product obtained under the multiple of 30um in embodiment 3. From Figure 9 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com