Epoxy microcapsule and preparation method thereof

A technology of microcapsules and epoxy resin, which is applied in the field of epoxy microcapsules and its preparation, can solve the problems of unfavorable shape and wall thickness, and achieve the effect of controlling and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of the epoxy microcapsules, comprising the following steps:

[0021] In the first step, the epoxy resin or its mixture is dispersed in water containing surfactant to form an emulsion.

[0022] In the second step, a curing agent or an aqueous curing agent solution is added to the emulsion and mixed uniformly to obtain a uniform system.

[0023] The third step is to change the temperature of the system while stirring to make the curing agent react with the epoxy resin.

[0024] In the fourth step, the precipitate is rinsed with water and dried to obtain epoxy resin microcapsules.

[0025] In the first step, the epoxy resin is a single component, insoluble in water, and the type of the epoxy resin is not limited. The composition of the epoxy resin mixture includes, in addition to the epoxy resin, one or more of a curing accelerator, a diluent, a solvent, a coupling agent, and a latent curing agent.

[0026] The surfactant is a nonionic surfactant or...

Embodiment 1

[0035] The first step, take 100 ml of water, 10 ml of 10wt% SMA (Scripset520) aqueous solution, 6 ml of 4wt% PVA (Mw=1500) aqueous solution, mix well, add 30 grams of bisphenol A epoxy resin E-51 (epoxy value = 0.54). Stir mechanically for 15 minutes at a speed of 400-600 rpm to obtain a stable oil-in-water epoxy resin emulsion.

[0036] In the second step, take 7 grams of m-phenylenediamine (molecular weight 108.14), add 20 grams of water to make a curing agent aqueous solution, slowly add it into the epoxy resin emulsion, stir at a low speed, and rotate at 100 rpm to obtain a uniform system.

[0037] In the third step, the temperature of the homogeneous system was raised to 70°C at the same time, and the reaction was held for 30 minutes, then the heating was stopped, and the stirring was stopped after cooling to room temperature to obtain a reaction liquid.

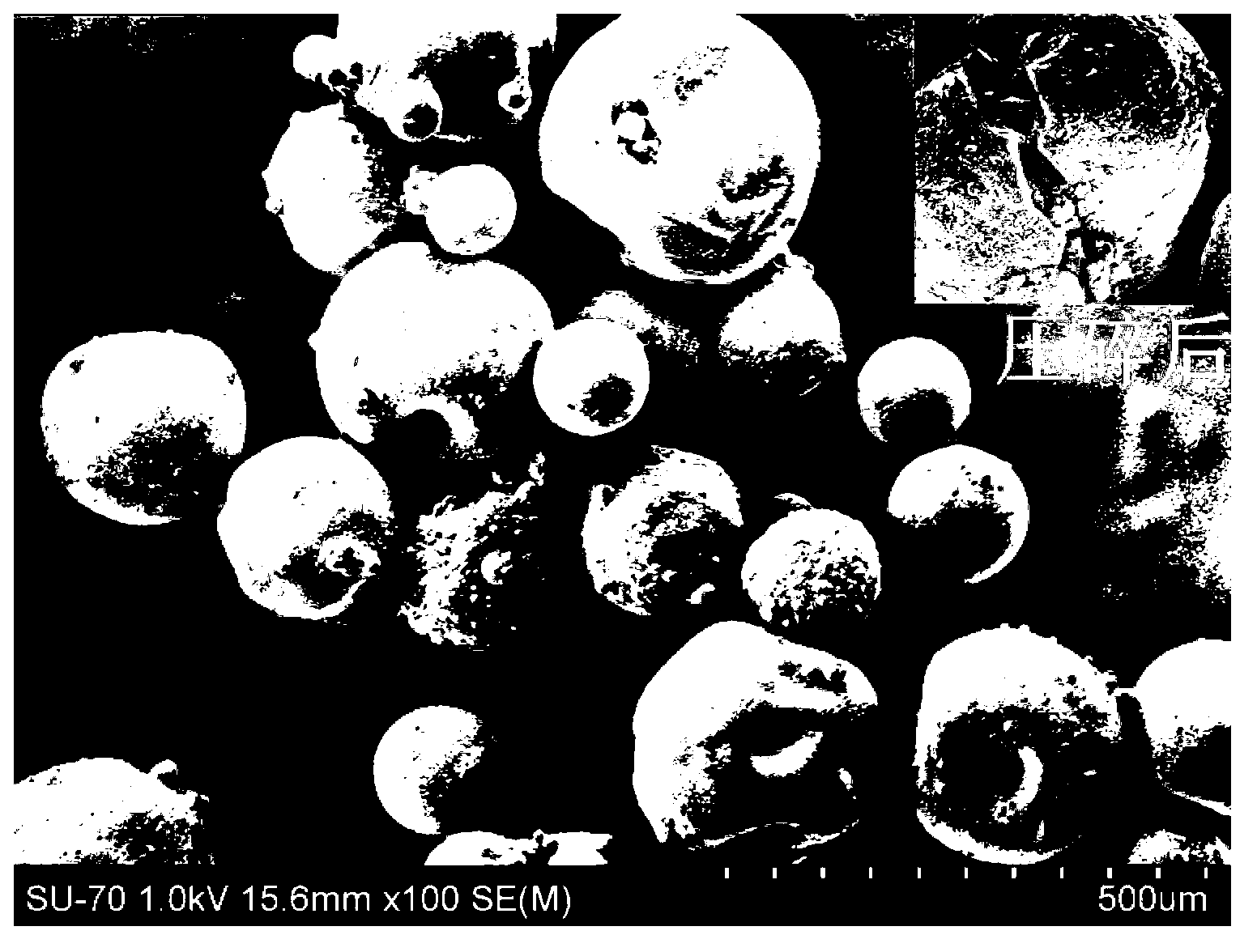

[0038] In the third step, the reaction solution was filtered, the filter cake was rinsed with 100 ml of water, and t...

Embodiment 2

[0041] In the first step, take 1000 ml of water, 100 ml of 10wt% SMA (Scripset520) aqueous solution, 60 ml of 4wt% PVA (Mw=1500) aqueous solution, and 88 grams of m-xylylenediamine (molecular weight 136.13), and mix well as the continuous phase.

[0042] In the second step, take 300 grams of low-viscosity epoxy E-58 (diglycidyl hexahydrophthalate, epoxy value = 0.58, viscosity 700mPa·s25°C) as the dispersed phase, and pass it through a high-flux SPG membrane emulsifier (SPG membrane specification: φ10×L125mm, pore size 50μm) emulsified to obtain epoxy E-58 emulsion with uniform droplet size.

[0043] In the third step, the temperature of the emulsion is raised to 80° C., and the stirring speed is slow at 50 revolutions per minute. After reacting for 15 minutes, it is cooled to room temperature, and the stirring is stopped.

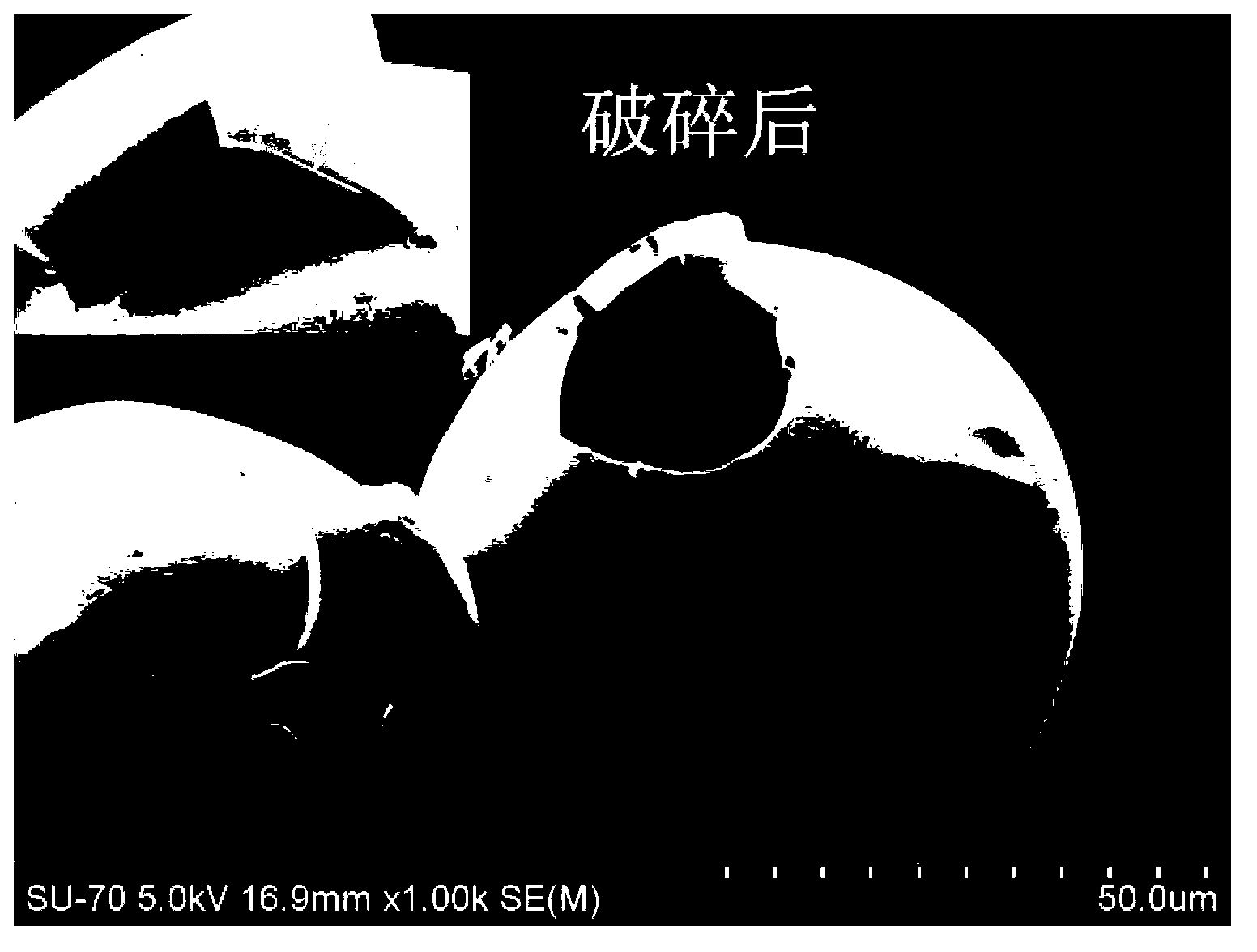

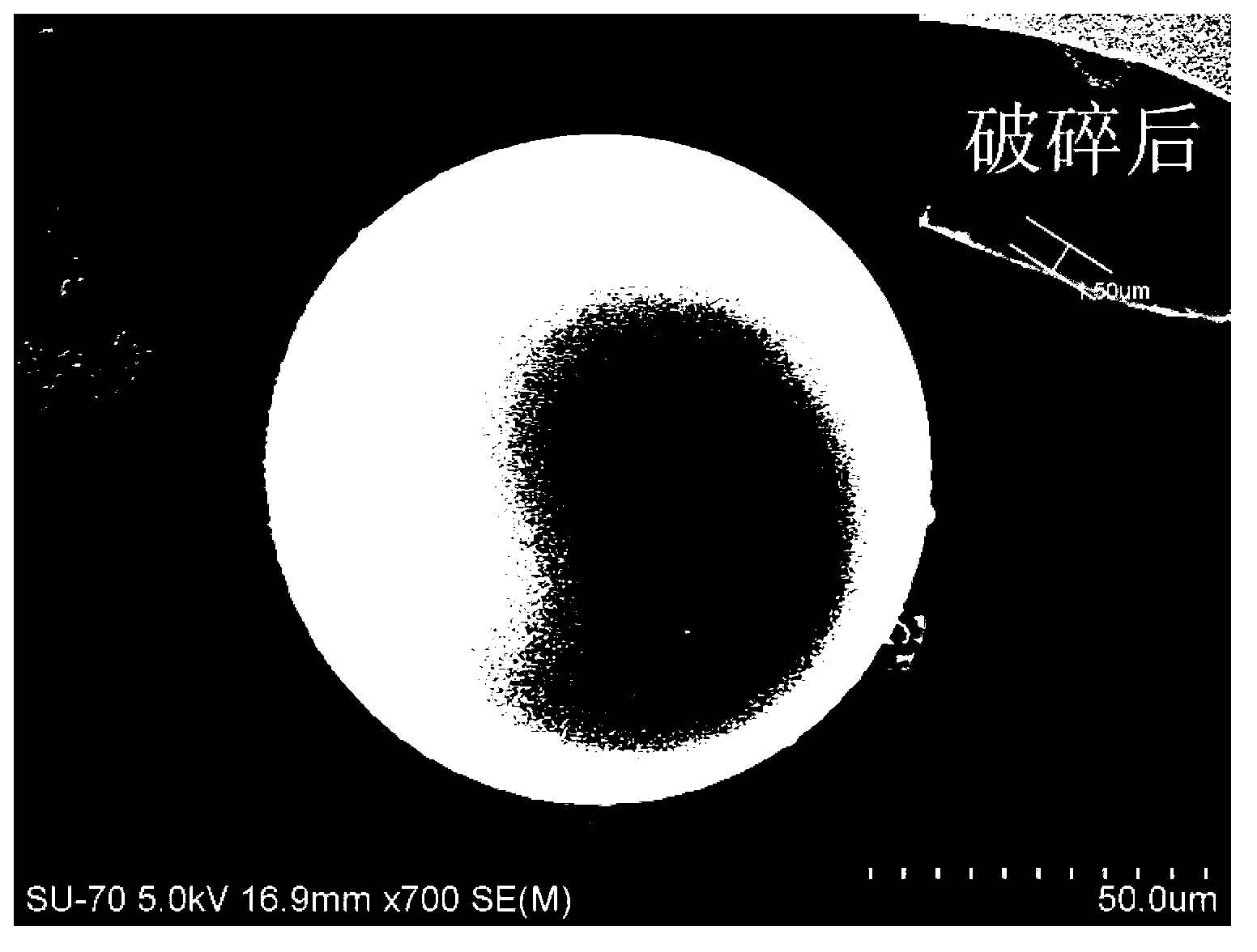

[0044] The fourth step is filtering, rinsing with 500 ml of water, filtering again, repeating 3 times, and finally drying at 40° C. for 5 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com