A water immersion phased array ultrasonic testing method for aluminum alloy pre-stretched plates

A technology of pre-stretching plate and detection method, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve the problems that the concentration and proficiency of the detection personnel are greatly affected, and achieve convenient calibration, improve detection efficiency, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

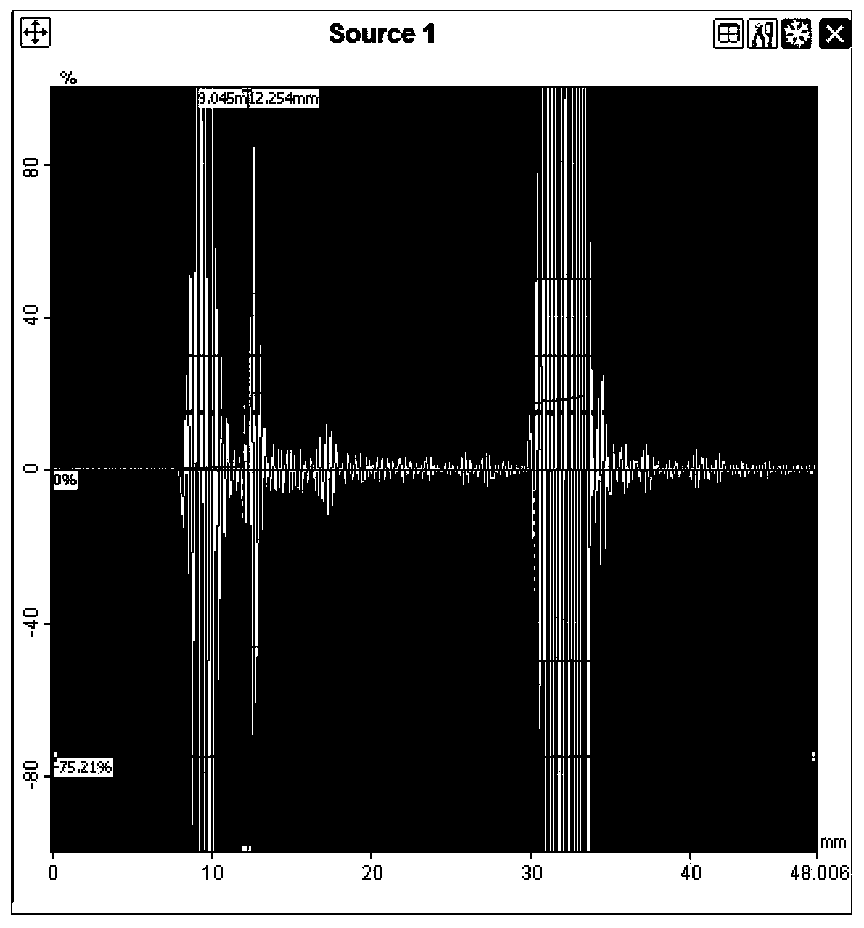

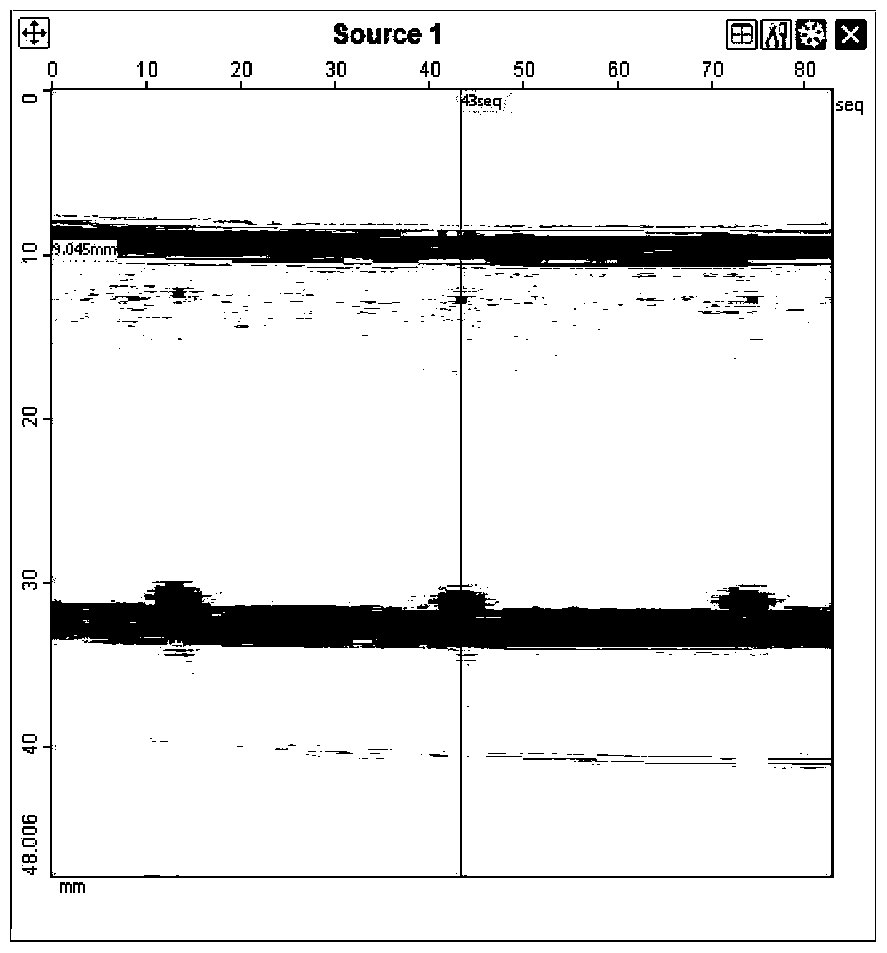

[0041] Detection method of the present invention, concrete steps are as follows:

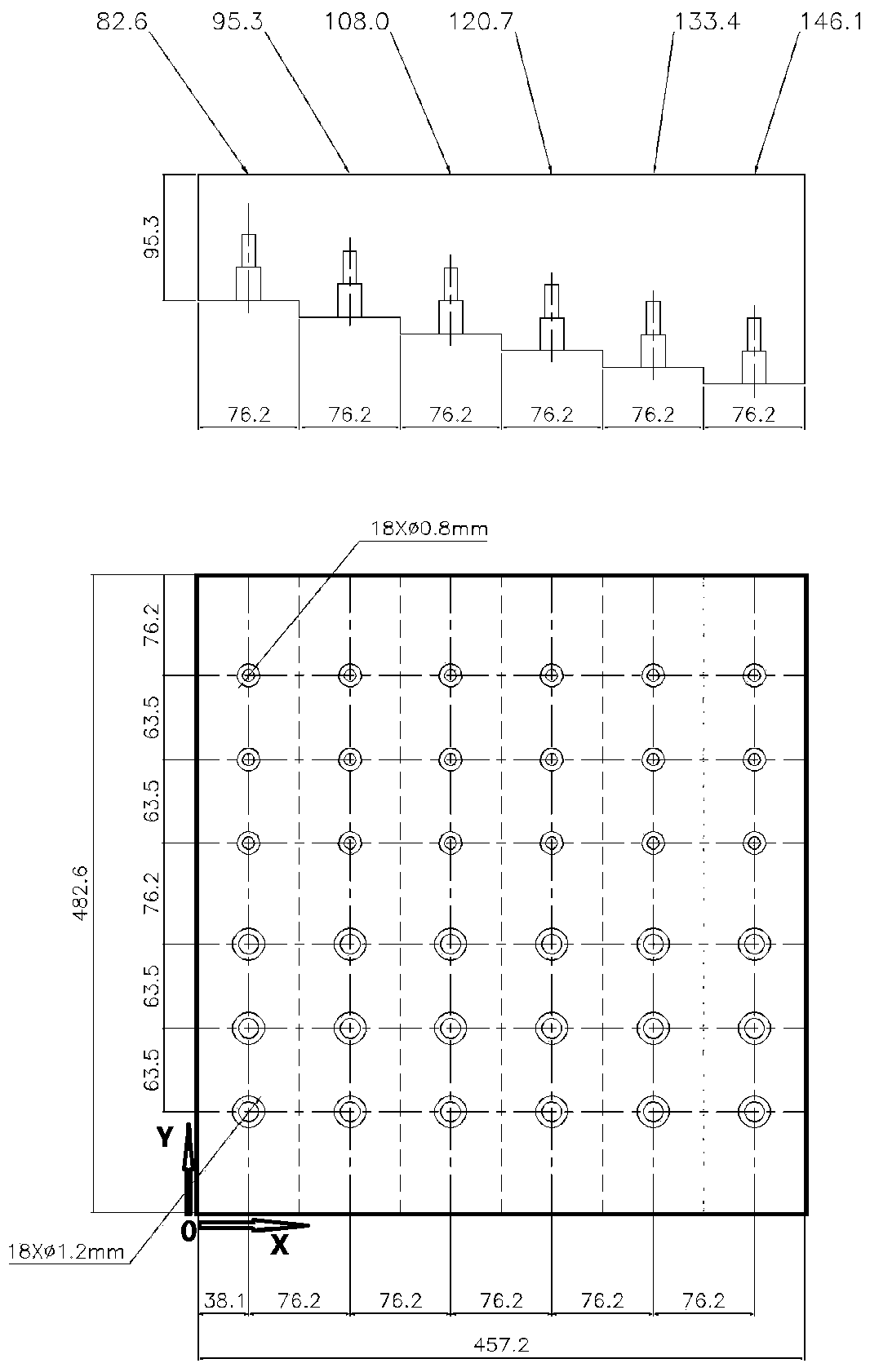

[0042] (1) Prepare a phased array ultrasonic detector, the number of chips of the phased array ultrasonic probe is 256, the chip width is 0.6 mm, the chip spacing is 0.1 mm, the chip height is 10 mm, and the probe frequency is 10 MHz. Select a complete set of flat-bottomed hole test blocks with an aperture specification of Φ0.8mm, and select a large-thickness aluminum alloy pre-stretched plate as the plate to be tested. The alloy grade of the plate to be tested selected in this embodiment is 7075, the length is 483mm, and the width is . 457mm, thickness 159mm, there are flat-bottomed holes with diameters of Φ0.8mm and Φ1.2mm with different sound paths in the plate, the distribution diagram of the flat-bottomed holes in the plate is as follows figure 1 The location, sound path and equivalent diameter of each flat-bottomed hole are shown in Table 1.

[0043] Place the plate to be tested on the li...

Embodiment 2

[0057] The concrete steps of detection method of the present invention are as follows:

[0058] (1) Prepare a phased array ultrasonic detector, the number of chips of the phased array ultrasonic probe is 256, the chip width is 0.6 mm, the chip spacing is 0.1 mm, the chip height is 10 mm, and the probe frequency is 10 MHz. Select a complete set of flat-bottomed hole test blocks with an aperture specification of Φ0.8mm, and select a large-thickness aluminum alloy pre-stretched plate as the plate to be tested. The alloy grade of the plate to be tested selected in this embodiment is 7075, the length is 482.6mm, and the width is 304.8mm. mm, thickness 25.4mm. There are flat-bottomed holes with diameters of Φ0.8mm and Φ1.2mm with different sound paths in the plate to be tested. The distribution diagram of the flat-bottomed holes in the plate is as follows Figure 4 The location, sound path and equivalent diameter of each flat-bottomed hole are shown in Table 2.

[0059] Place the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com