Treatment method of nano nickel powder for sulfur-containing multi-layer ceramic chip capacitor

A multi-layer ceramic and nano-nickel powder technology, which is applied in the treatment field of nano-nickel powder, can solve the problems of unstable coating of sulfur-containing organic compounds, difficulty in guaranteeing the stability of sulfur content, and inability to ensure low impurity of powders, etc. Low shrinkage, stable sulfur content, and excellent oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Use nano-nickel powder with an average particle size of 270-300nm prepared by PVD method as a raw material, add it to deionized water, and mix the solid-liquid system, and its solid content is controlled at 30%.

[0037] (2) Use an emulsifier to emulsify and disperse the above solid-liquid system. The dispersion time is maintained for 30 minutes, and the temperature of the slurry is controlled at 20°C~35°C.

[0038] (3) Add glacial acetic acid with a solid content of 2% mass to the solid-liquid system obtained in the above (2), stir ultrasonically for 75 minutes, and then filter out the acid liquid from the above solid-liquid system through magnetic plate adsorption.

[0039] (4) Add deionized water to the slurry after filtering out the acid liquid to make the solid content at 20%, stir it mechanically for 5 minutes, then absorb the solid-liquid system through a magnetic plate to filter out the upper liquid, and use pH test paper or pH The meter detects the pH of th...

Embodiment 2

[0046](1) Nano-nickel powder with an average particle size of 180-220nm prepared by PVD method is used as a raw material, and it is added to deionized water, and the solid content is controlled at 30%.

[0047] (2) Use an emulsifier to emulsify and disperse the above solid-liquid system, maintain the dispersion time for 30 minutes, and control the slurry temperature at 20°C~35°C.

[0048] (3) Add 2% powder weight of glacial acetic acid to the above solid-liquid system, stir it ultrasonically for 75 minutes, and then filter out the acid liquid by absorbing the above solid-liquid system through a magnetic plate.

[0049] (4) Add deionized water to the slurry after filtering out the acid liquid to make the solid content at about 20%, stir it mechanically for 5 minutes, then absorb the solid-liquid system through a magnetic plate to filter out the upper liquid, and use PH test paper or PH The meter detects the pH of the upper liquid.

[0050] (5) Repeat (4) until the pH is 6-7. A...

Embodiment 3

[0056] According to the same process of embodiment 1, the nickel powder of the same particle size range, the same organic acid treatment, only the sulfur-containing organic matter 0.25% quality tripolythiocyanate is replaced with 0.4% quality 2-mercaptobenzothiazole, Obtain embodiment 3 nickel powder.

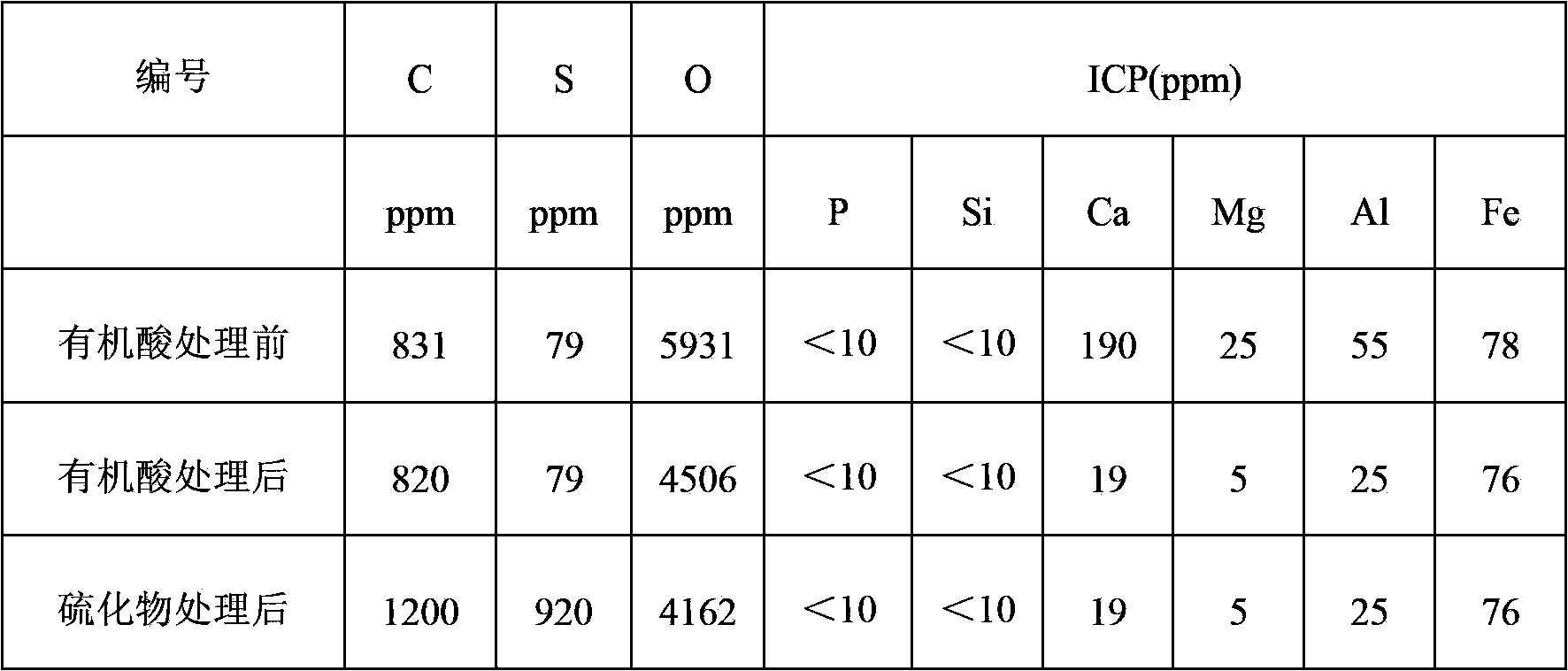

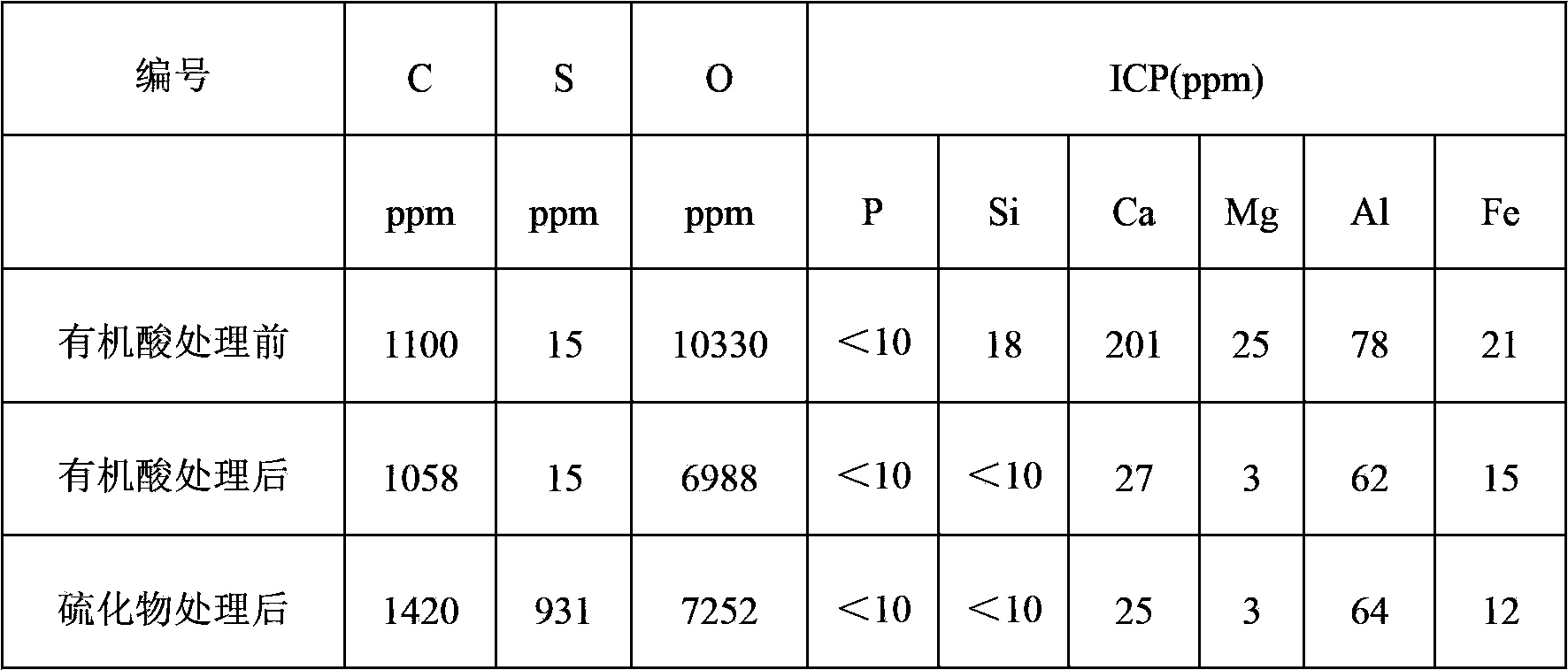

[0057] Table 3 is the production process inspection data of 270~300nm low-impurity sulfur-containing nickel powder process

[0058]

[0059]

[0060] From the above three groups of results, it can be seen that under the same process conditions, the contents of Ca and Mg of nickel powders with different particle sizes have been significantly reduced after being treated with organic acids, and the content of Al impurities has also been reduced correspondingly. The oxygen content also decreased significantly before and after treatment, especially when the particle size was smaller, indicating that the hydroxide contained in the nickel powder was effectively removed. At the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com