Method for preparing cyclohexanone oxime by ammoximation of cyclohexanone

A technology of cyclohexanone ammonia oxime and cyclohexanone oxime, which is applied in the field of preparation of cyclohexanone oxime by cyclohexanone ammonia oxime, can solve the problems of difficult control of reaction temperature, high equipment investment cost, large amount of waste water, etc., and achieve effective It is beneficial to large-scale industrial production, solves the separation problem, and increases the effect of filtering area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

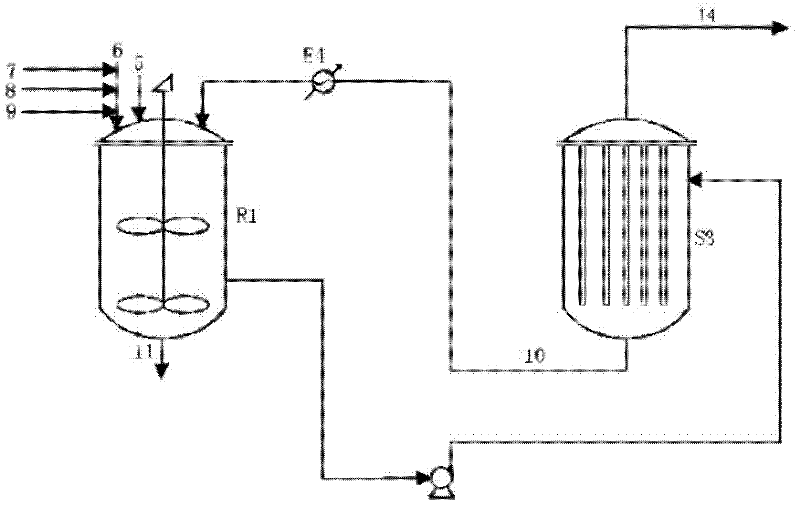

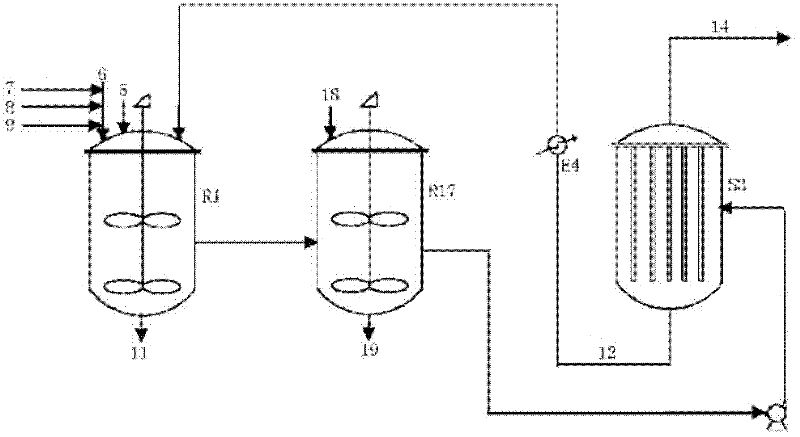

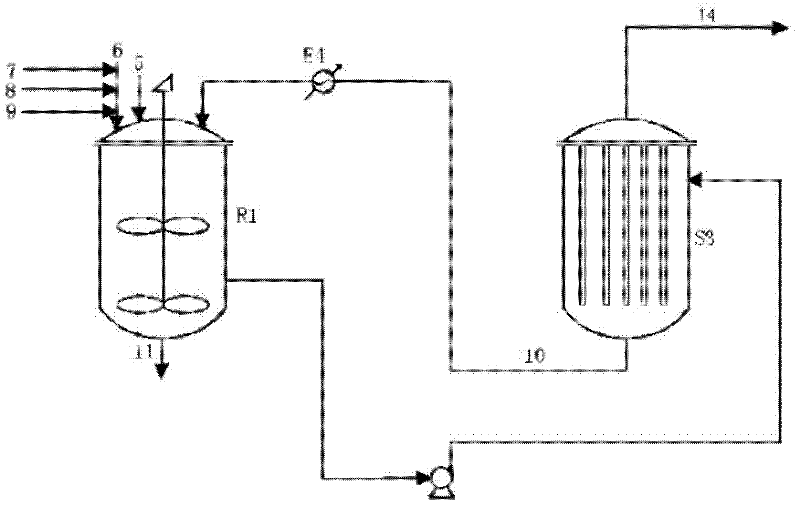

Method used

Image

Examples

Embodiment 1

[0038] Concrete feed parameters and reaction conditions are as follows:

[0039] Cyclohexanone=100 gram / hour; Tertiary butyl alcohol=470 gram / hour; 27.5% (wt) hydrogen peroxide=140 gram / hour; The amount of ammonia is to maintain the concentration of ammonia in the reaction solution as about 2% (wt) (61 grams / hour); titanium silicon molecular sieve concentration = 2.0% (wt).

[0040] The average residence time of the materials in the reactor is 66 minutes, the reaction temperature is maintained at 85±1°C through jacket heat exchange, and the reaction pressure is maintained at 0.35MPa.

[0041] Its reaction result is as follows:

[0042] The conversion rate of cyclohexanone: 97.6%; the conversion rate of hydrogen peroxide: 100%; the reaction selectivity calculated by cyclohexanone: 99.7%; the effective utilization rate of hydrogen peroxide: 91.4%; the yield of cyclohexanone oxime: 97.3%.

Embodiment 2

[0044] Concrete feed parameters and reaction result are as follows:

[0045] Cyclohexanone=100 grams / hour; Tertiary butyl alcohol=470 grams / hour; 35% (wt) hydrogen peroxide=110 grams / hour; The amount of ammonia gas is to maintain the concentration of ammonia in the reaction solution to be about 2% (wt); Molecular sieve concentration = 2% (wt).

[0046] The average residence time of materials in the reactor is 70 minutes, the reaction temperature is controlled at 85±1°C, and the reaction pressure is maintained at 0.35MPa.

[0047] The result of the reaction is as follows:

[0048] The conversion rate of cyclohexanone: 98.1%; the conversion rate of hydrogen peroxide: 100%; the reaction selectivity in terms of cyclohexanone: 99.7%; the effective utilization rate of hydrogen peroxide: 91.4%; the yield of cyclohexanone oxime: 97.8%.

Embodiment 3

[0050] Concrete feed parameters and reaction result are as follows:

[0051] Cyclohexanone=100 gram / hour; Tertiary butyl alcohol=470 gram / hour; 50% (wt) hydrogen peroxide=76 gram / hour; The amount of ammonia gas is to maintain the concentration of ammonia in the reaction solution to be about 2% (wt); Molecular sieve concentration = 2% (wt).

[0052] The average residence time of materials in the reactor is 72 minutes, the reaction temperature is controlled at 85±1°C, and the reaction pressure is maintained at 0.35MPa.

[0053] The result of the reaction is as follows:

[0054] The conversion rate of cyclohexanone: 98.5%; the conversion rate of hydrogen peroxide: 100%; the reaction selectivity calculated by cyclohexanone: 99.6%; the effective utilization rate of hydrogen peroxide: 89.8%; the yield of cyclohexanone oxime: 98.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com