Method for producing synthetic natural gas SNG from coal and processing installation thereof

A synthetic natural gas and coal gasification technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of complex process, long process, high investment, etc., achieve high heat recovery rate, long service life, and increase heat transfer intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

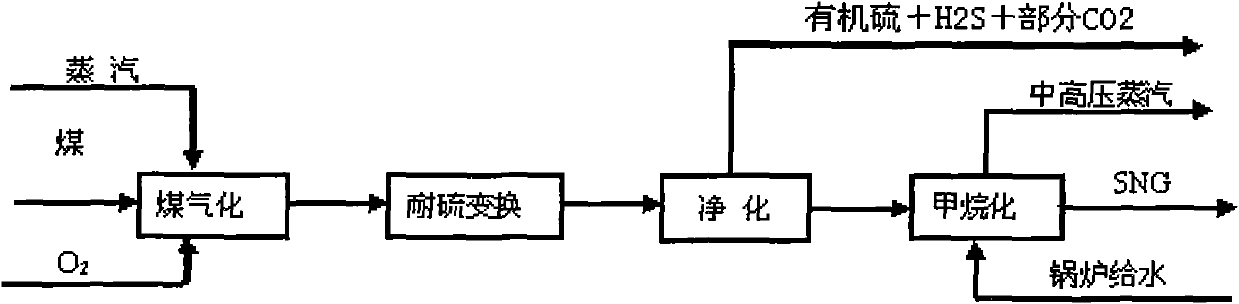

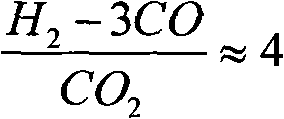

[0027] like figure 1 Shown, coal, steam and O 2 The crude gas is produced in a pressurized gasifier (normal pressure, 3.0Mpa, 4.0Mpa). When the crude gas undergoes sulfur-resistant conversion, the H can be adjusted. 2 , CO and CO 2 At the same time, most of the organic sulfur in the gas is converted into inorganic sulfur. When the converted gas passes through the gas purification process, the organic and inorganic sulfur are removed, so that the total sulfur in the gas is ≤0.1ppm, and part of the CO is also removed. 2 , so that the stoichiometric ratio is reached in the purified gas: In the methanation process of the purified gas, the methanation reaction is completed due to the action of the Ni-based catalyst, that is, SNG (synthetic natural gas) is generated, and CO in the methanated gas is released. 2 and H 2 The content of all ≤ 0.1% (VOL), CO content can not be measured. The heat of reaction is taken away by strong flowing water to produce medium and high pressure s...

Embodiment 2

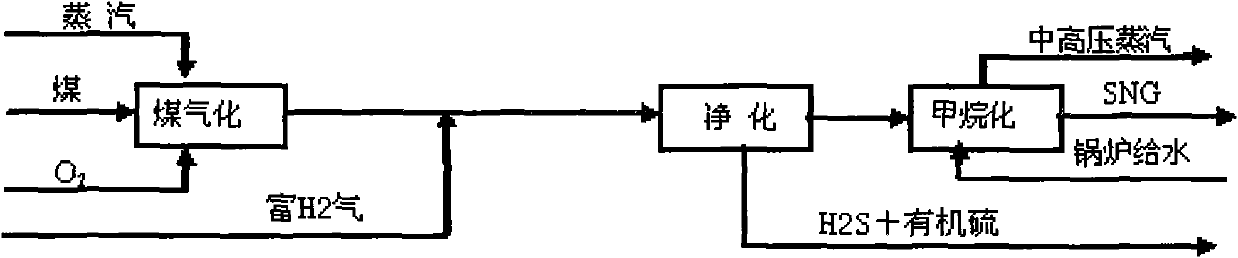

[0029] like figure 2 Shown, coal, steam and O 2 Raw gas, raw gas and external H-rich gas are produced in a pressurized gasifier (normal pressure, 3.0Mpa, 4.0Mpa) 2 Gas (could be coke oven gas or other H 2 Gas with high content) mixed, the mixed gas should meet the stoichiometric ratio: requirements. When the mixed gas is purified, the H in the gas 2 S and organic sulfur are removed, and the purified gas must meet the requirement that its total sulfur content is ≤0.1PP. In the methanation process of the purified gas, due to the action of the Ni-based catalyst, the CO 2 , CO and H 2 Carry out methanation reaction to synthesize CNG (synthetic natural gas), and remove CO from the CNG gas in the methanation process 2 and H 2 The content of each is less than or equal to 0.1% (VOL), and the CO content cannot be measured. The heat of reaction is taken away by strong flowing water to produce medium and high pressure steam.

[0030]In addition, the SNG in this embodiment can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com