Method for synthesizing dimethyl ether by adopting biomass indirect liquification one-step process

A technology of biomass and dimethyl ether, which is applied in the field of synthesizing dimethyl ether by utilizing biogas reforming biomass gasification gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

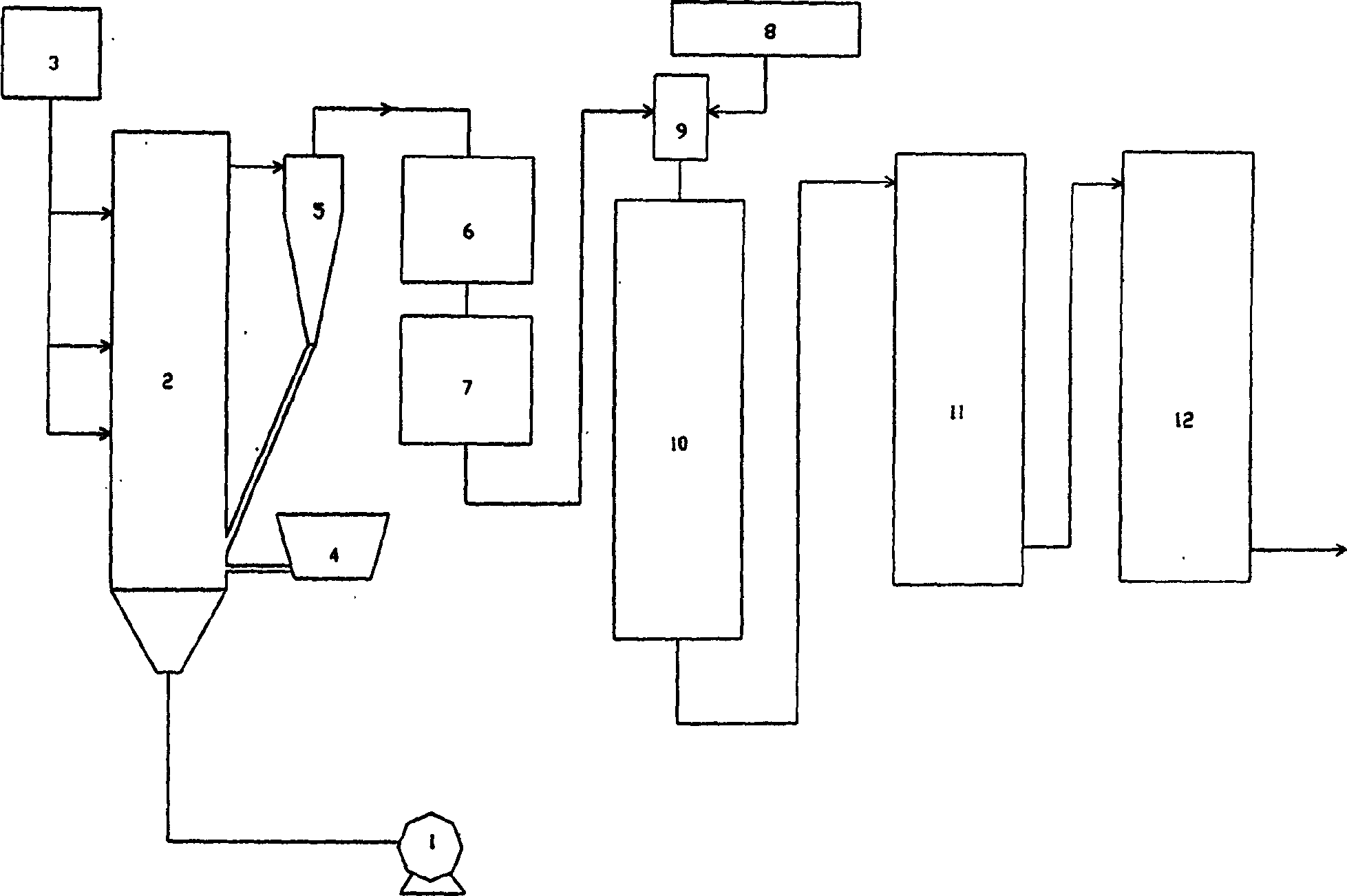

[0016] The biomass fir powder enters the fluidized bed gasification furnace (2) from the screw feeder (4), the air is blown in from the lower part of the gasification furnace (2) through the Luo secondary fan, and the high-temperature water produced by the steam generator (3) Steam (400K) enters the gasifier (2) at different heights, and the biomass undergoes air-steam catalytic gasification in the gasifier (2), and the H in the gasification gas 2 :CO:CO 2 :N 2 The ratio is 30:10:20:30; the gasified gas from the gasifier (2) enters the tar cracker (6) for catalytic cracking of tar after the cyclone separator (5) removes dust and coke, and the tar content is lower than 50 mg / N m 3 , the water washing spray tower (7) deeply purifies the gasification gas; the biogas produced by the biogas generator (8) is purified and mixed with the gasification gas through the mixer (9) and then enters the reforming reactor (10) catalytic reforming system Take synthesis gas, H in the synthes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com