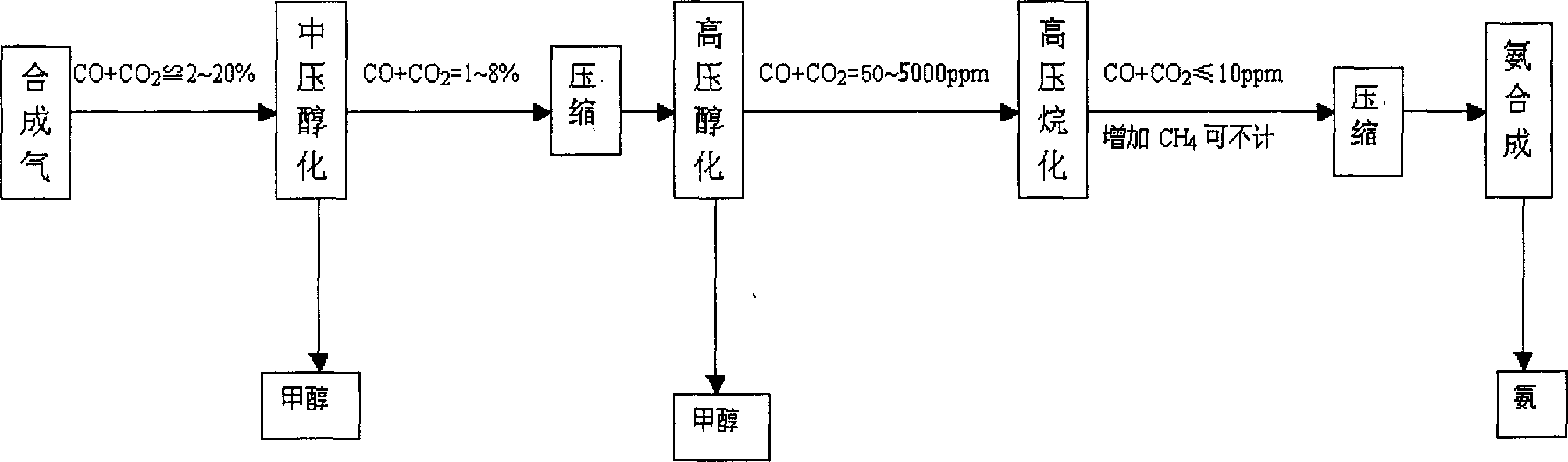

Non-isostatic alcoholization alkylation process for purifying raw gas for ammonia synthesis

A kind of raw material gas, the technology of synthesizing ammonia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

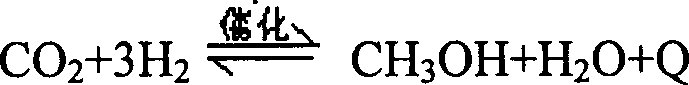

Method used

Image

Examples

Embodiment 1

[0042] Pass the synthesis gas into the φ1200mm medium-pressure alcoholization tower, the pressure is 15Mpa, the temperature is controlled at 210-270°C, so that it contains 3-10% CO+CO 2 The synthetic gas is synthesized into methanol under medium pressure, and the CO+CO is exported 2 Control it at 1-4%, pressurize, send the pre-purified synthesis gas into a φ1000mm high-pressure alcoholization tower, the pressure is 30.0Mpa, the temperature is controlled at 210-270°C, so that 1-4% CO+CO in the synthesis gas 2 Convert to methanol, export CO+CO 2 Control at ≤200ppm, send the deeply purified synthesis gas into a φ800mm high-pressure alkylation tower for alkylation, control the pressure at 30.0Mpa, control the temperature at 230-300°C, and export CO+CO 2 For <10ppm, the synthesis gas enters the ammonia synthesis. The alcohol ammoniation of the system is 0.1-0.4.

Embodiment 2

[0044] Pass the synthesis gas into the φ1600mm medium-pressure alcoholization tower, the pressure is 12.0Mpa, the temperature is controlled at 210-260°C, so that it contains 2-3% CO+CO 2 The synthetic gas is synthesized into methanol under medium pressure, and the CO+CO is exported 2 Control at 1.0-2.0%, pressurize, send the pre-purified synthesis gas into a φ1400mm high-pressure alcoholization tower, the pressure is 23.0Mpa, the temperature is controlled at 210-260°C, so that 1.0-2.0% CO+CO in the synthesis gas 2 Convert to methanol, export CO+CO 2 Control at ≤600ppm, send the deeply purified synthesis gas into a φ1400mm high-pressure alkylation tower for alkylation, control the pressure at 23.0Mpa, control the temperature at 250-350°C, and export CO+CO 2 ≤10ppm, the synthesis gas enters the ammonia synthesis. The alcohol ammoniation of this system is 0.06~0.2.

Embodiment 3

[0046] Pass the synthesis gas into the φ1200mm medium-pressure alcoholization tower, the pressure is 5Mpa, the temperature is controlled at 210-280°C, so that it contains 5-10% CO+CO 2 synthetic gas to methanol, export CO+CO 2Control it at 2-6%, pressurize, send the pre-purified synthesis gas into a φ1000mm high-pressure alcoholization tower, the pressure is 16.0Mpa, the temperature is controlled at 210-280°C, so that 2-6% CO+CO in the synthesis gas 2 Convert to methanol, export CO+CO 2 Control at ≤4000ppm, send the deeply purified synthesis gas into a φ800mm high-pressure alkylation tower for alkylation, control the pressure at 30.0Mpa, control the temperature at 250-350°C, and export CO+CO 2 For <10ppm, the synthesis gas enters the ammonia synthesis. The alcohol ammoniation of the system is 0.4-1.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com