Vacuum cleaner having wet cleaning function

a vacuum cleaner and wet cleaning technology, which is applied in the direction of vacuum cleaners, floor scrubbing machines, carpet cleaners, etc., can solve the problems of soiled area around the vacuum cleaner, shortened and complicated structure of the brush assembly, etc., to achieve the effect of simple structure and shortening the cleaning time for wet cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Exemplary embodiments of the present invention will be described in detail with reference to the annexed drawings. In the drawings, the same elements are denoted by the same reference numerals throughout the drawings in the following description, detailed descriptions of known functions and configurations incorporated herein have been omitted for conciseness and clarity.

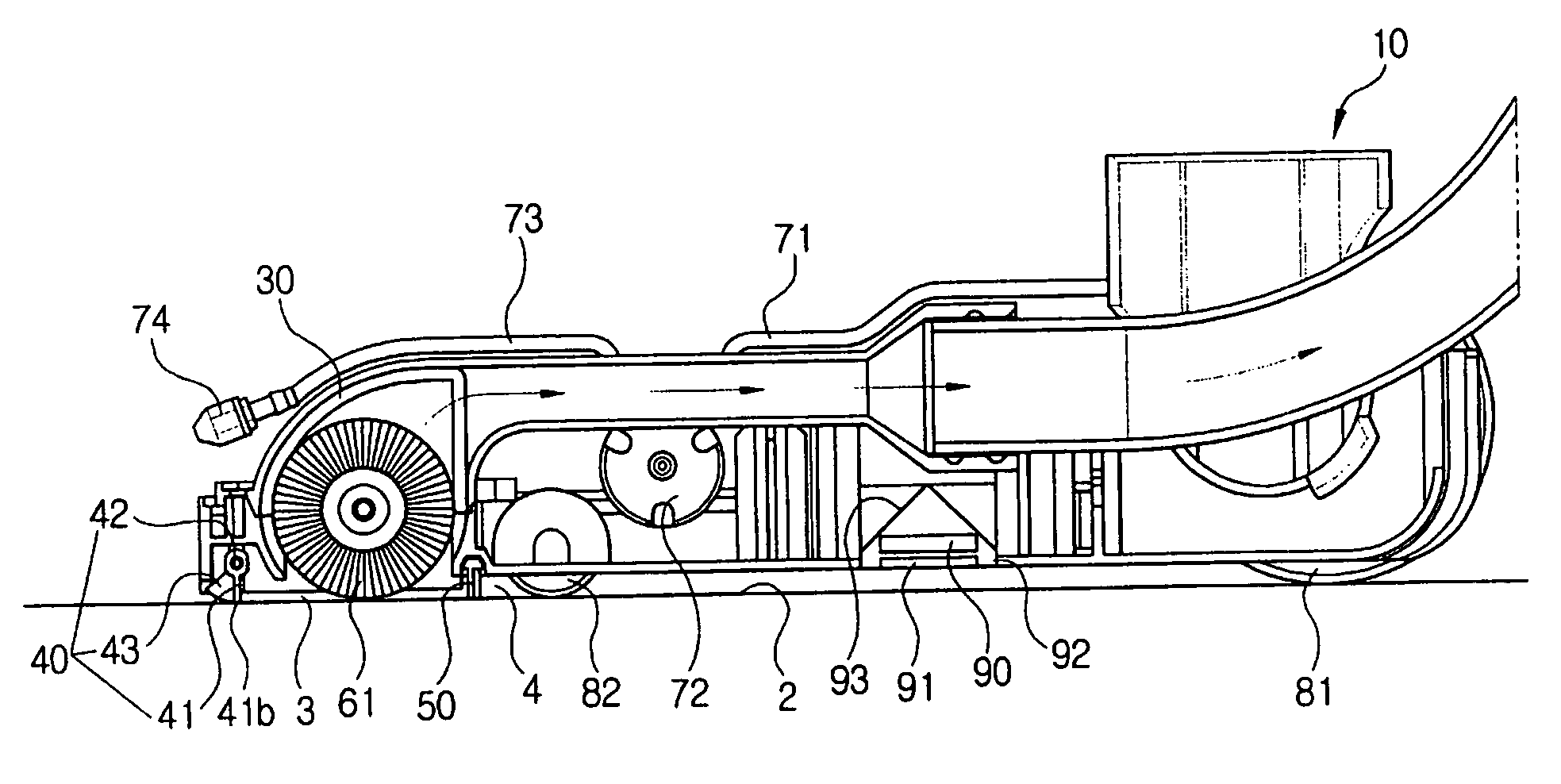

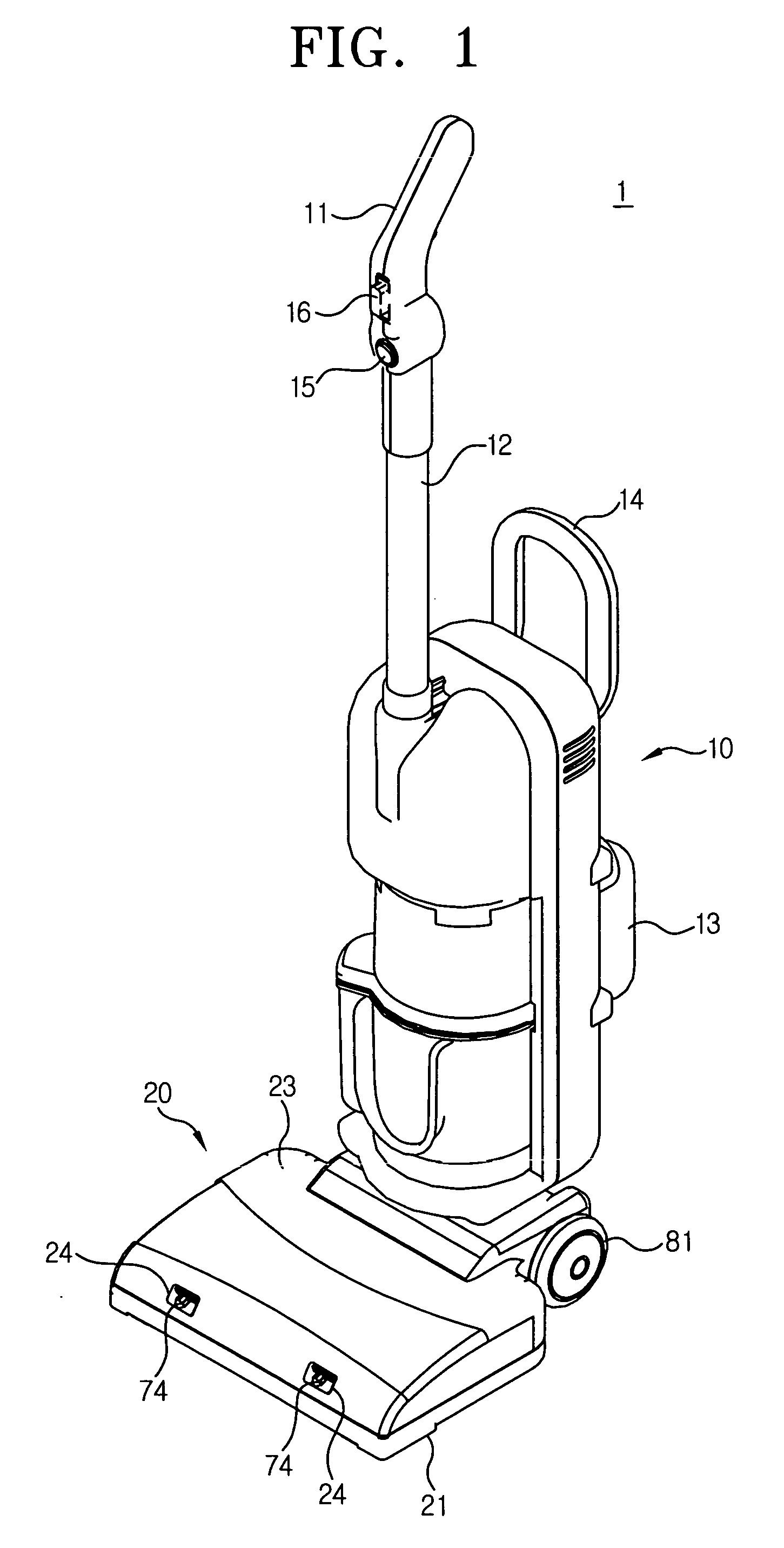

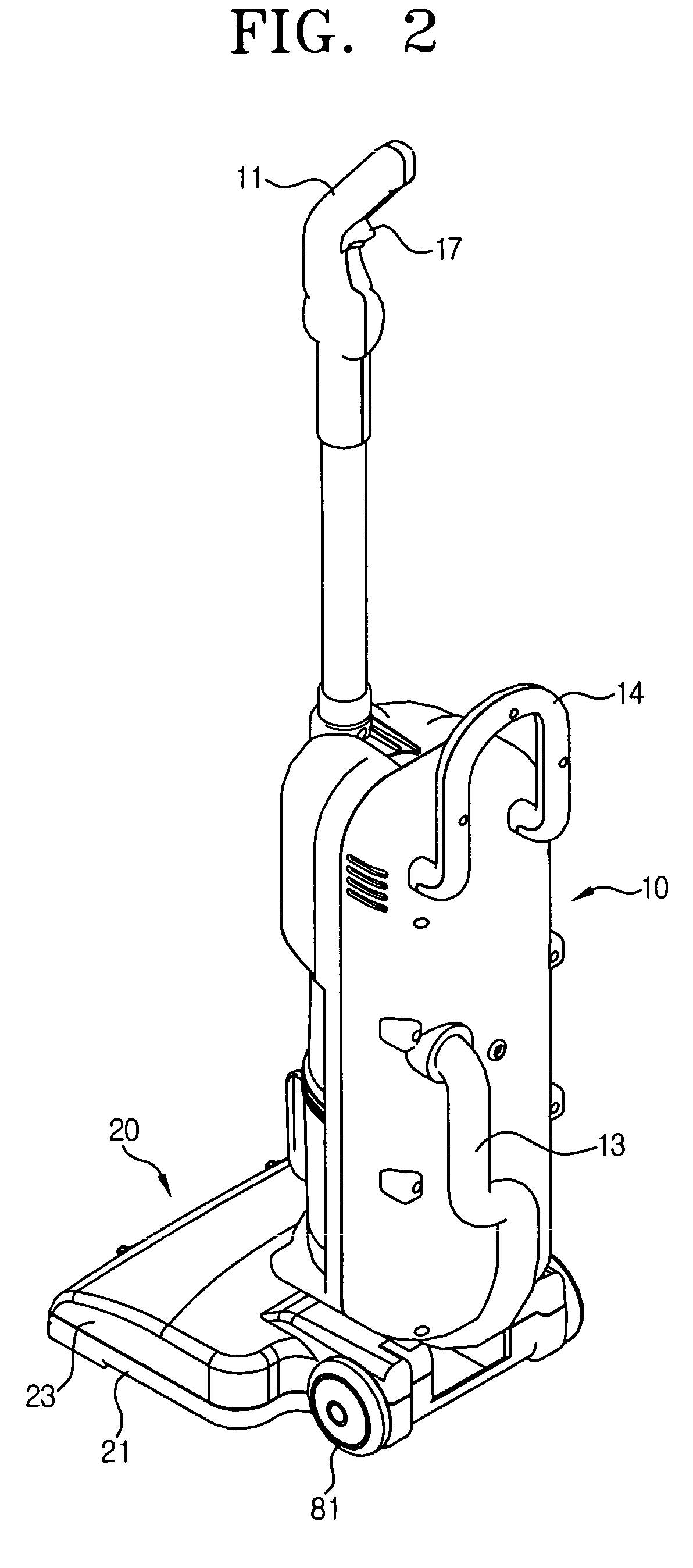

[0034] Referring to FIG. I and FIG. 2, a vacuum cleaner 1 with a wet cleaning function comprises a main body 10 and a brush assembly 20.

[0035] The main body 10 comprises a motor assembly (not shown) for generating a suction force, a contaminant-collecting receptacle (not shown) for collecting contaminants and water drawn in via the brush assembly 20, and a water tank (not shown) for storing water for wet cleaning. The body 10 has at an upper end a handle 11 for a user to grasp. The handle 11 is connected via an extension pipe 12 to the main body 10. The body 10 has at a rear side a hose 13 for connecting the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com