Methods of making articles having toughened and untoughened regions

a technology of region and hardening, applied in the direction of superimposed coating process, manufacturing tools, liquid/solution decomposition chemical coating, etc., can solve the problems of foreign objects sometimes undetected entering the engine, affecting the overall weight of the article, so as to increase the overall weight and increase the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

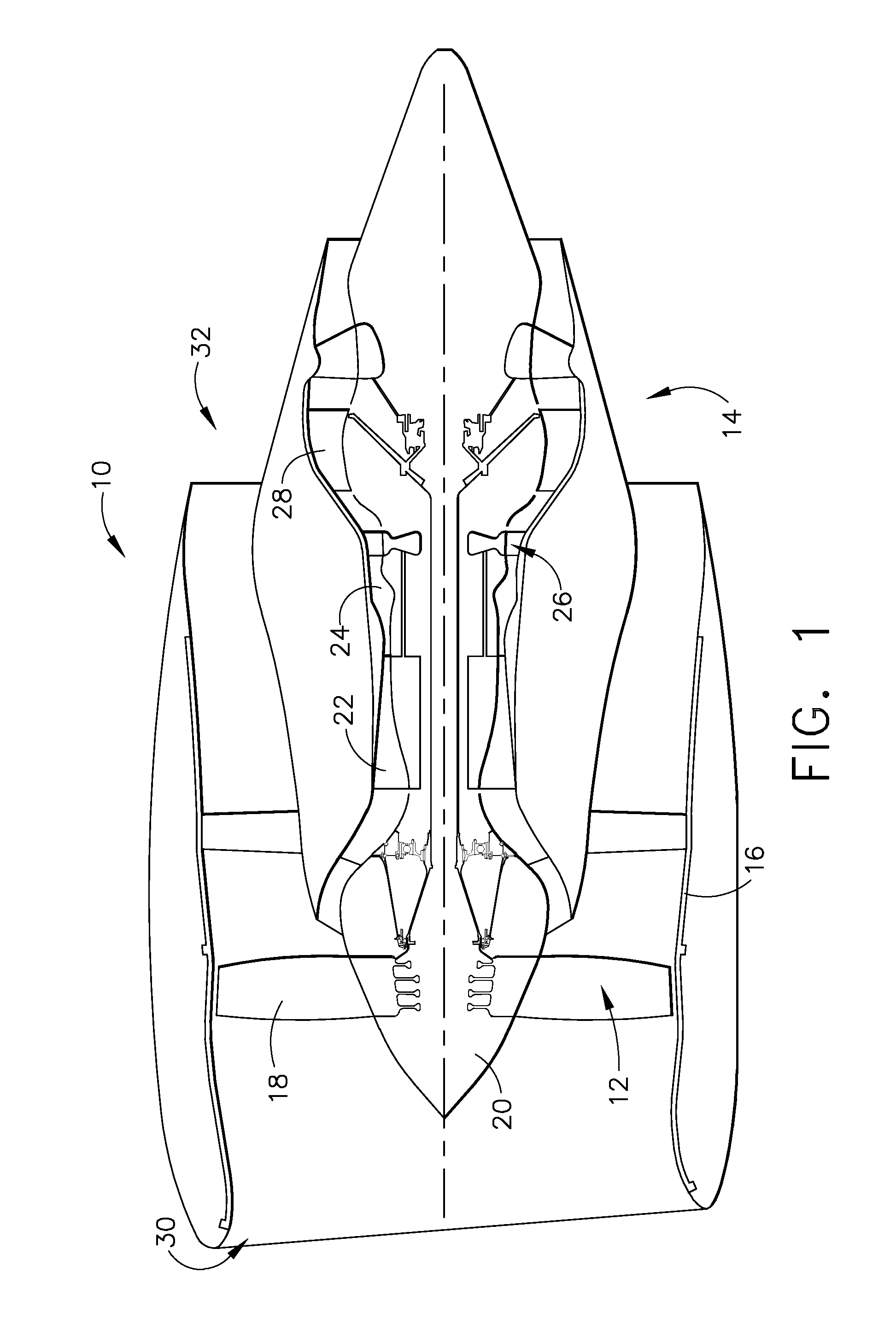

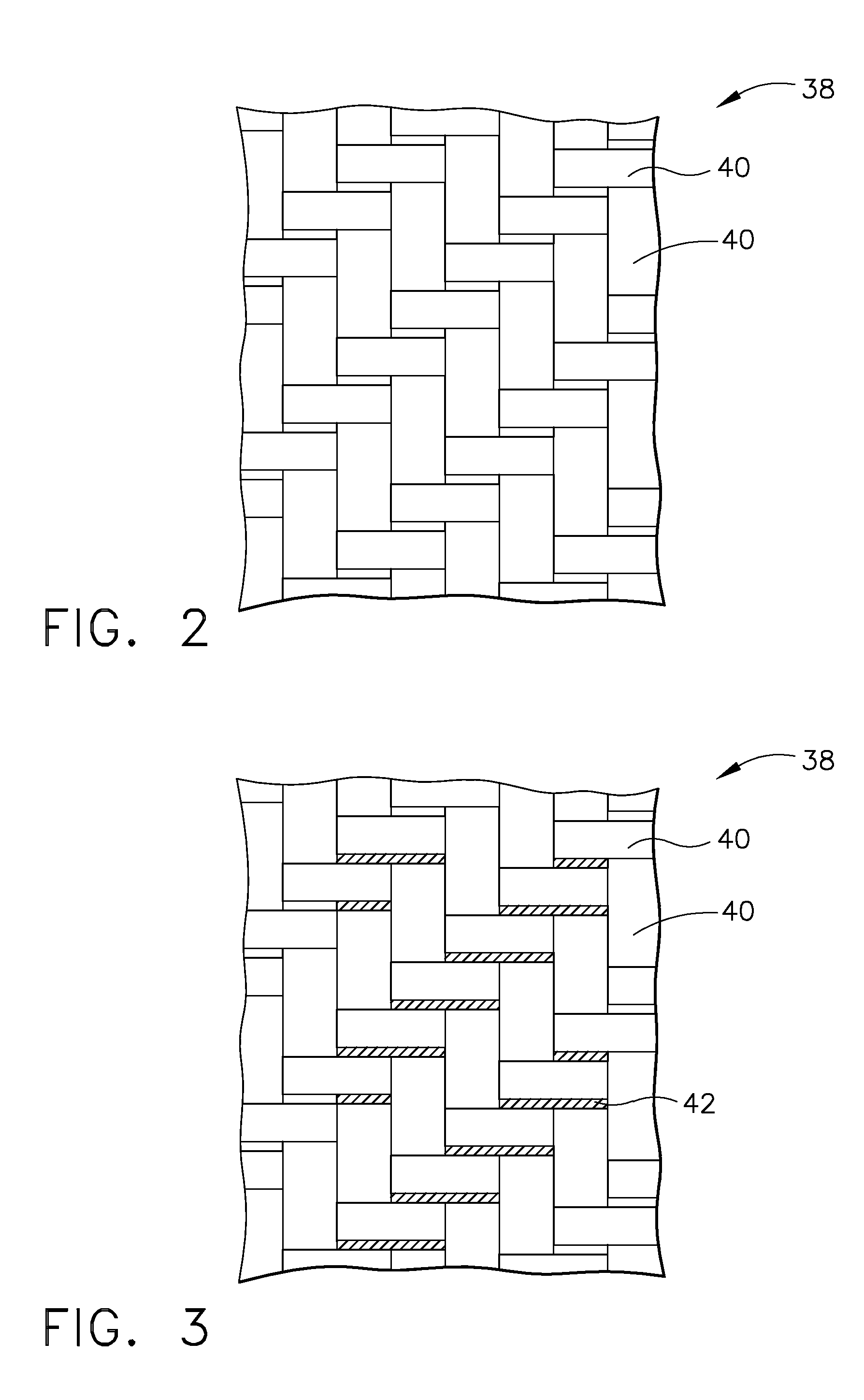

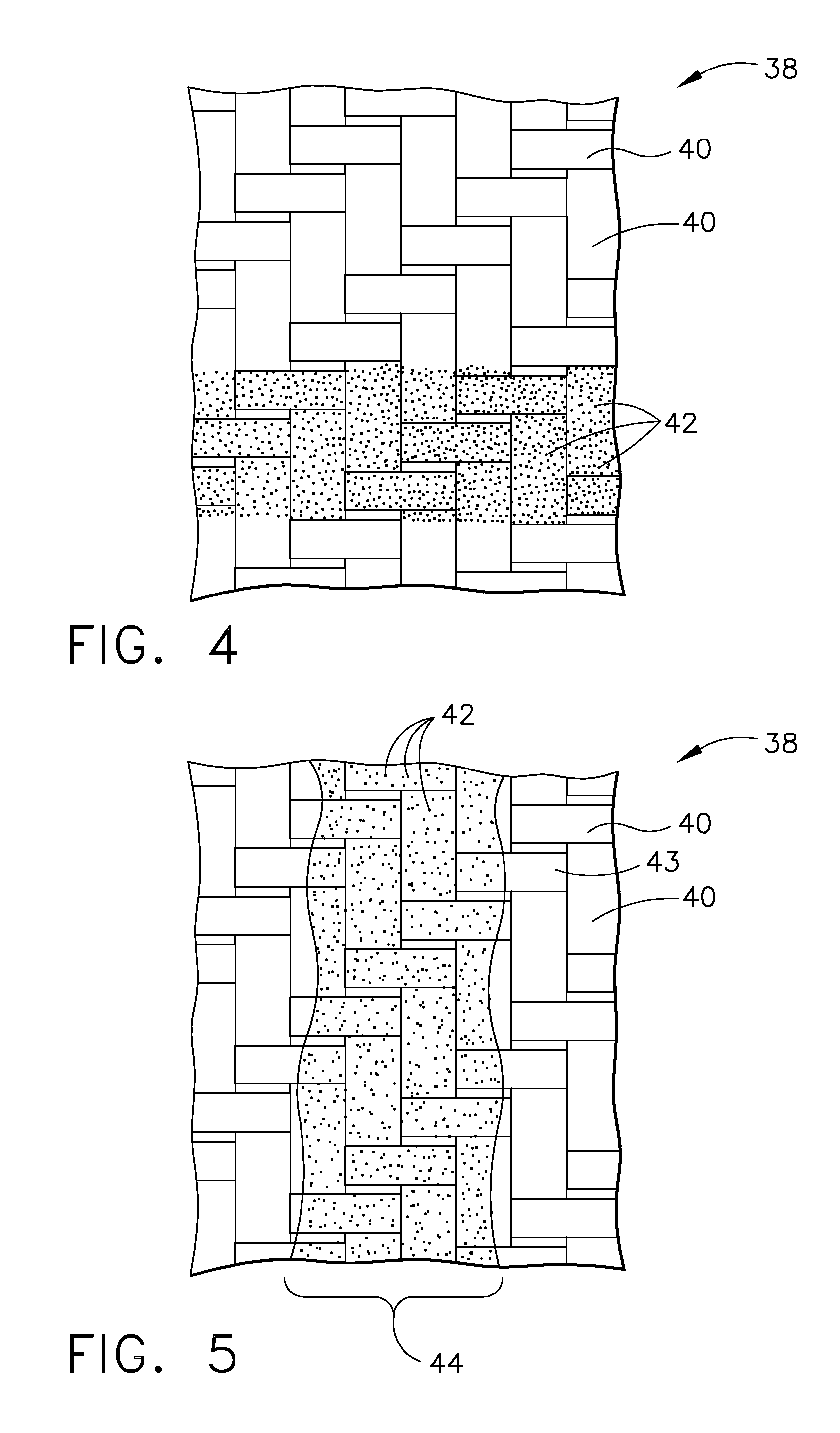

[0021]Embodiments described herein generally relate to methods for making articles having at least one toughened region and at least one untoughened region. Generally, such methods can comprise providing a material, applying a toughening agent to a portion of the material, shaping the material to produce a preform, applying an untoughened resin to the preform, and curing the preform having the applied untoughened resin wherein the toughened region corresponds to the portion of the material comprising the toughening agent. While embodiments herein may generally focus on methods for making composite fan casings for gas turbine engines, it will be understood by those skilled in the art that the description should not be limited to such. Indeed, as the following description explains, the methods described herein may be used to make any article or composite material having at least one toughened region and at least one untoughened region.

[0022]Turning to the figures, FIG. 1 is a schemati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fracture toughness | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com