Method for preparing ZSM-35 molecular sieve

A technology of ZSM-35 and molecular sieve, applied in the field of preparing ZSM-35 molecular sieve, can solve the problems of long crystallization time, large grain size of ZSM-35 molecular sieve, low crystallinity, etc., to shorten the crystallization time and improve the mass transfer rate. , the effect of crystallinity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

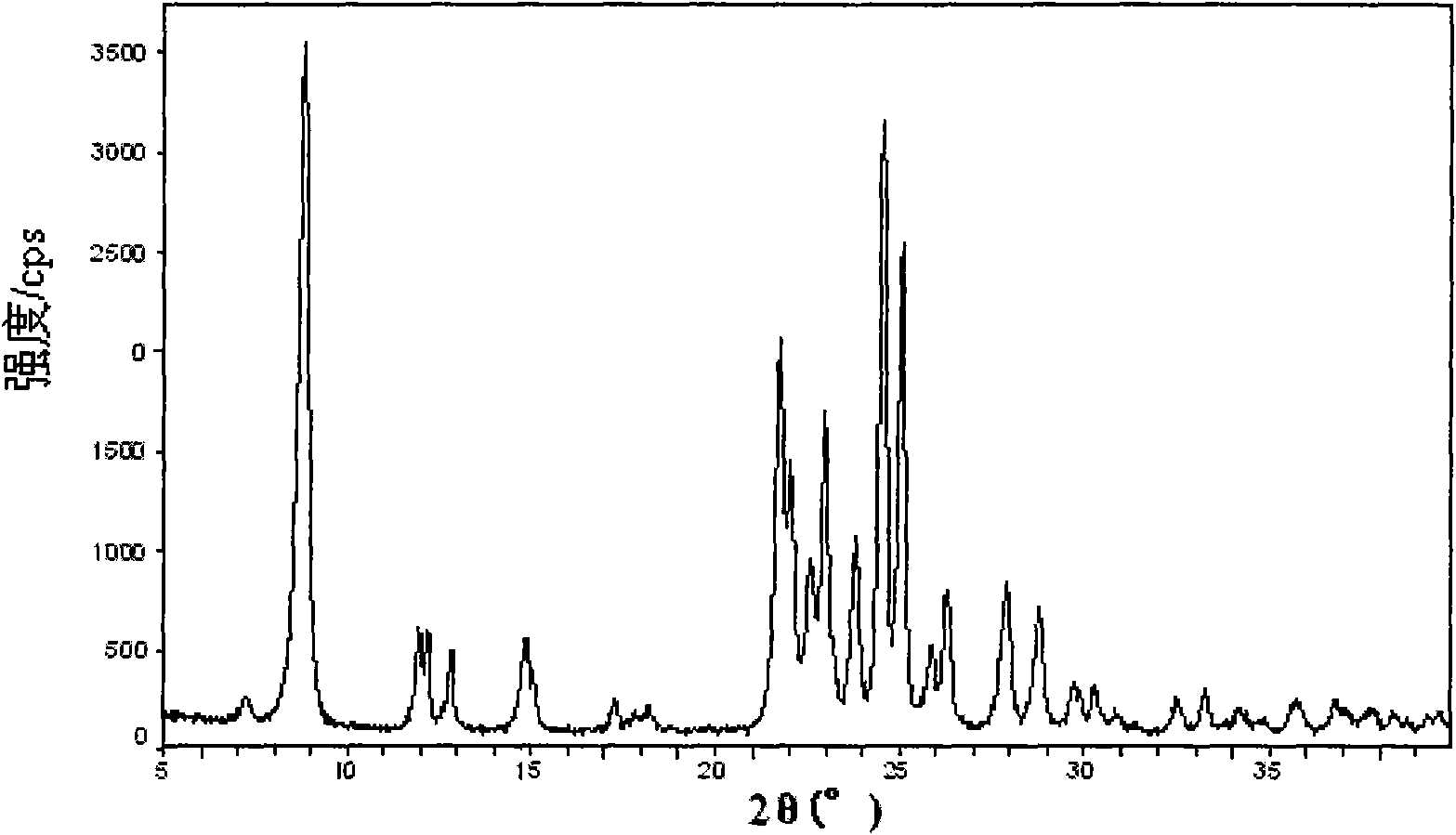

[0034] First, 8.3 grams of aluminum sulfate (analytical pure, content greater than 99.5%) was added to 23.5 ml of deionized water under stirring at room temperature, and stirred for 40 minutes. After the aluminum sulfate is completely dissolved, slowly add 67.5 grams of silica sol (SiO 2 content is 22.2% silica sol), stirred for 1 hour, and then slowly added 10 ml of 0.5 mol / L sodium hydroxide aqueous solution to form a colloidal solution. The colloidal solution was placed in an aqueous medium at 70° C. and treated with an ultrasonic wave with a frequency of 40 kHz for 90 minutes, so that the colloidal solution was fully aged and dispersed. Then turn off the ultrasound, cool to room temperature, add 7.5ml cyclohexylamine as a template agent and 0.36g ZSM-35 molecular sieve powder as a seed crystal, stir evenly to prepare a reaction mixture. The mixture has the following molar composition: OH-: Al 2 o 3 : SiO 2 :R:H 2 O=0.2:0.05:1:0.3:20. The reaction mixture was transfer...

Embodiment 2

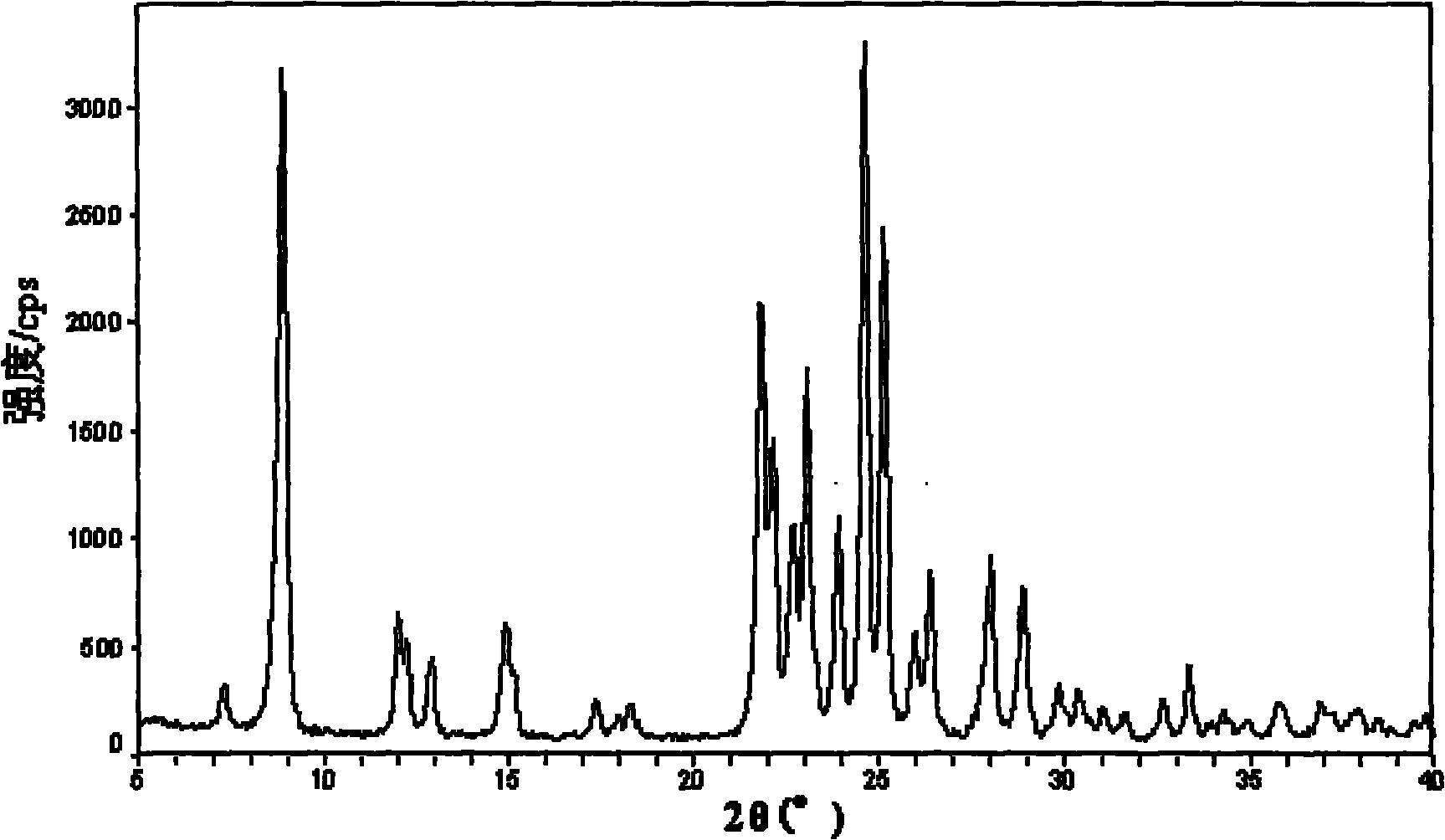

[0036] First, 8.3 grams of aluminum sulfate (analytical pure, content greater than 99.5%) was added to 23.5 ml of deionized water under stirring at room temperature, and stirred for 40 minutes. After the aluminum sulfate is completely dissolved, slowly add 67.5 grams of silica sol (SiO 2 content is 22.2% silica sol), stirred for 1 hour, and then slowly added 10 ml of 0.5 mol / L sodium hydroxide aqueous solution to form a colloidal solution. The colloidal solution was placed in an aqueous medium at 70° C. and treated with an ultrasonic wave with a frequency of 50 kHz for 65 minutes, so that the colloidal solution was fully aged and dispersed. Then turn off the ultrasound, cool to room temperature, add 10.1ml ethylenediamine as a template agent and 0.36g ZSM-35 molecular sieve powder as a seed crystal, and stir evenly to prepare a reaction mixture. This mixture has the following molar composition: OH - :Al 2 o 3 : SiO 2 :R:H 2 O=0.2:0.05:1:0.6:20. After the reaction mixtur...

Embodiment 3

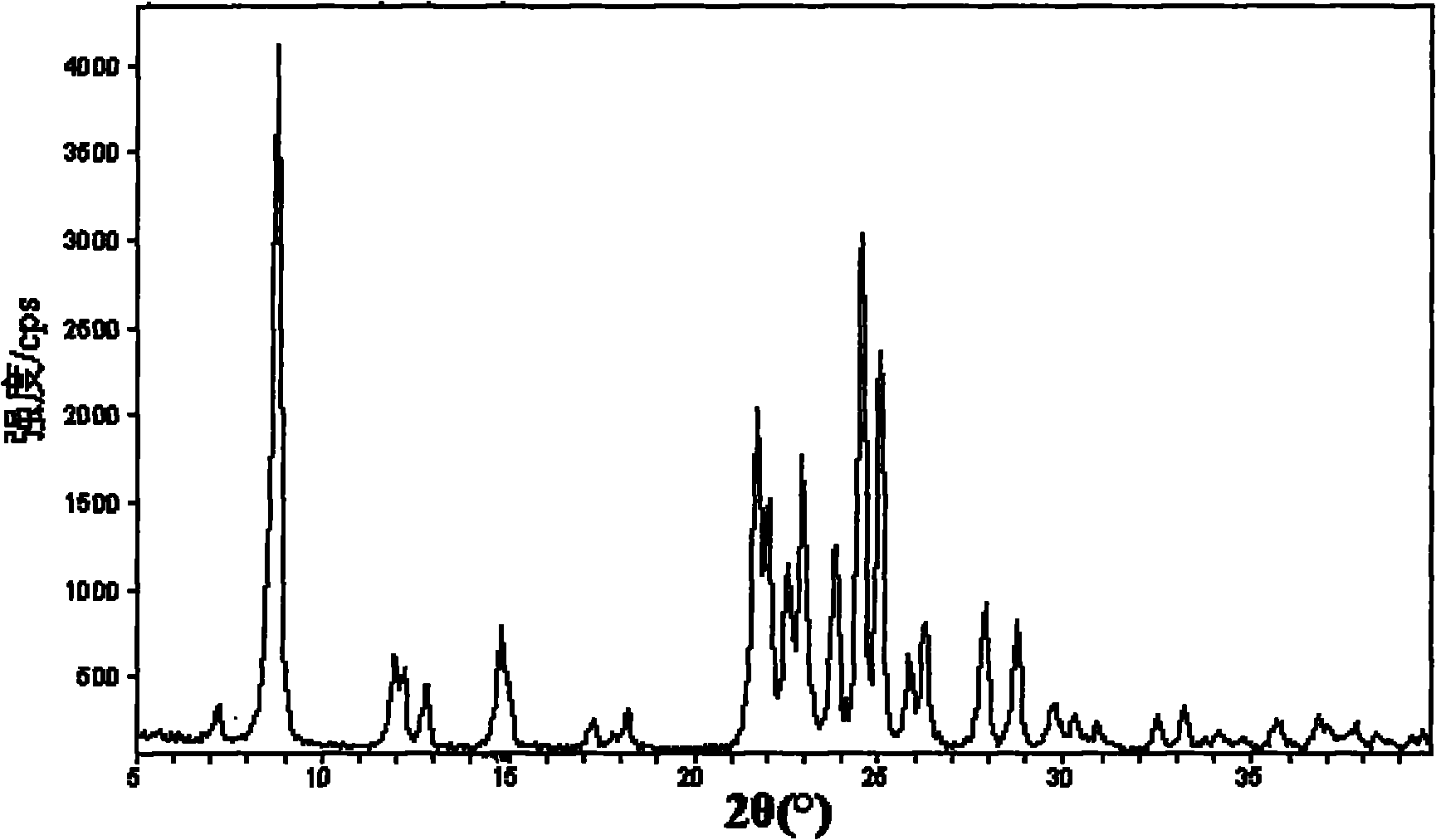

[0038] First, 8.3 grams of aluminum sulfate (analytical pure, content greater than 99.5%) was added to 23.5 ml of deionized water under stirring at room temperature, and stirred for 40 minutes. After the aluminum sulfate is completely dissolved, slowly add 33.7 grams of silica sol (SiO 2 content is 22.2% silica sol), stirred for 1 hour, and then slowly added 10 ml of 0.5 mol / L sodium hydroxide aqueous solution to form a colloidal solution. The colloidal solution was placed in an aqueous medium at 70° C. and treated with an ultrasonic wave with a frequency of 40 kHz for 70 minutes, so that the colloidal solution was fully aged and dispersed. Then turn off the ultrasound, cool to room temperature, add 7.5ml cyclohexylamine as a template agent and 0.36g ZSM-35 molecular sieve powder as a seed crystal, stir evenly to prepare a reaction mixture. This mixture has the following molar composition: OH - :Al 2 o 3 : SiO 2 :R:H 2 O=0.4:0.1:1:0.6:27. The reaction mixture was transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com