Method for preparing corrosion-resisting and self-cleaning coating

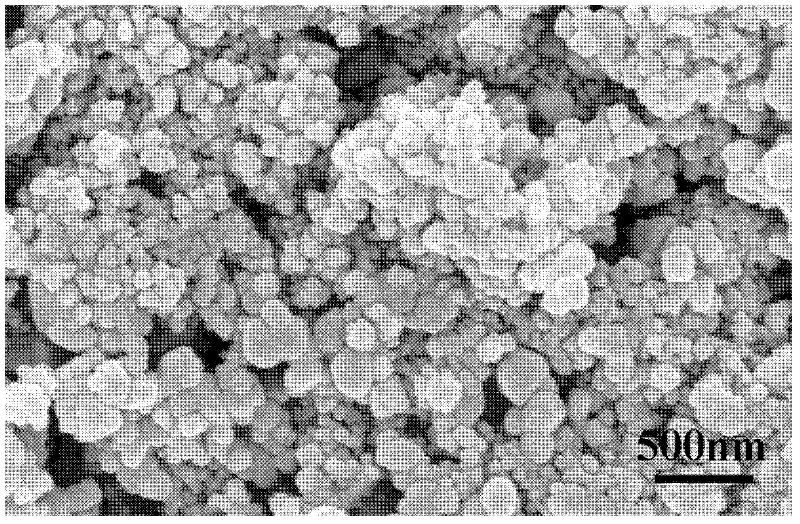

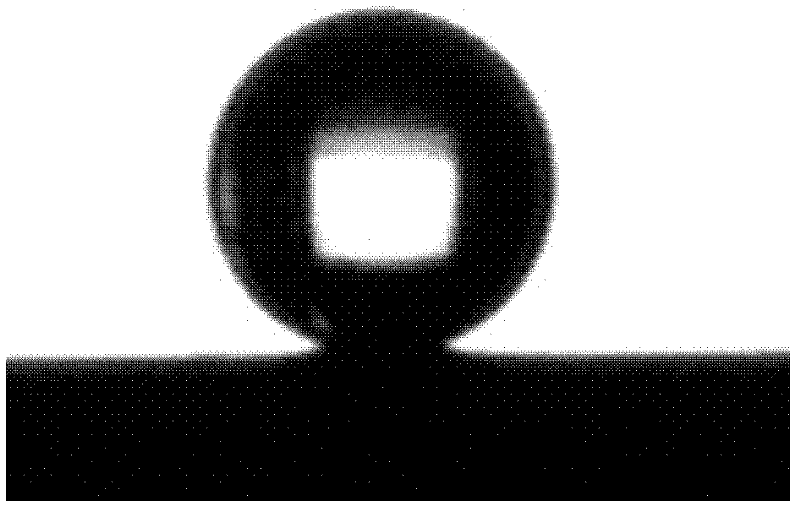

A self-cleaning coating, corrosion-resistant technology, applied in the direction of coating, metal material coating process, solid-state chemical plating, etc., can solve problems such as corrosion resistance research, achieve low equipment requirements, improve surface morphology, improve The effect of superhydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Clean the Hastelloy substrate used in the experiment with an ultrasonic cleaner and air dry it. The cleaning steps are as follows: put the Hastelloy alloy substrate into acetone, ethanol and deionized water for ultrasonic cleaning for 10 minutes respectively; 2 CO 3 25g / L, Na 3 PO 4 25g / L) at 80°C for 4 hours, then rinsed with deionized water and ultrasonically washed to completely remove the grease and pollutants on the surface.

[0034] 2. Preparation of TiO 2 sol 1, put the Hastelloy alloy base material into the sol 1 for dipping and pulling, and then dry and solidify on the surface of the Hastelloy alloy base material to obtain an oxide connection layer.

[0035] The specific steps are: mix 20mL ethanol and 1mL acetyl ethyl acetate evenly, add 4mL tetrabutyl titanate, stir for 1 hour, slowly add 0.2mL deionized water, stir for 10 hours, and age for 24 hours to obtain TiO 2 Sol 1; soak the cleaned Hastelloy substrate in TiO 2 After 3 minutes in Sol 1, pull...

Embodiment 2

[0043] 1. Clean the Hastelloy substrate used in the experiment with an ultrasonic cleaner and air dry it. The cleaning steps are: put the Hastelloy alloy substrate into acetone, ethanol and deionized water for 10 minutes for ultrasonic cleaning; then put it into lye (containing: NaOH 15g / L, NaOH 2 CO 3 25g / L, Na 3 PO 4 25g / L) at 80°C for 4 hours, rinsed with deionized water and ultrasonically washed to completely remove the grease and pollutants on the surface.

[0044] 2. Preparation of TiO 2 Sol 1, put the Hastelloy alloy base material into the sol 1 to dip and pull, dry and solidify to obtain the oxide connection layer. The specific steps are: mix 20mL ethanol and 1mL acetyl ethyl acetate evenly, add 4mL tetrabutyl titanate, stir for 1 hour, slowly add 0.2mL deionized water, stir for 10 hours, and age for 24 hours to obtain TiO 2 Sol 1; soak the cleaned Hastelloy substrate in TiO 2 After 3 minutes in Sol 1, pull out at a speed of 2-3mm / s, and after standing at room ...

Embodiment 3

[0050] 1. Clean the Hastelloy substrate used in the experiment with an ultrasonic cleaner and air dry it. The cleaning steps are: put the Hastelloy alloy substrate into acetone, ethanol and deionized water for 10 minutes for ultrasonic cleaning in turn; 2 CO 3 25g / L, Na 3 PO 4 25g / L) at 80°C for 4 hours, rinsed with deionized water and ultrasonically washed to completely remove the grease and pollutants on the surface.

[0051] 2. Preparation of TiO 2 Sol 1, put the Hastelloy alloy base material into the sol 1 to dip and pull, dry and solidify to obtain the oxide connection layer. The specific steps are: mix 20mL ethanol and 1mL acetyl ethyl acetate evenly, add 4mL tetrabutyl titanate, stir for 1 hour, slowly add 0.2mL deionized water, stir for 10 hours, and age for 24 hours to obtain TiO 2 Sol 1; soak the cleaned Hastelloy substrate in TiO 2 After 3 minutes in Sol 1, pull out at a speed of 2-3mm / s, and after standing at room temperature for 5 minutes, repeat the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com