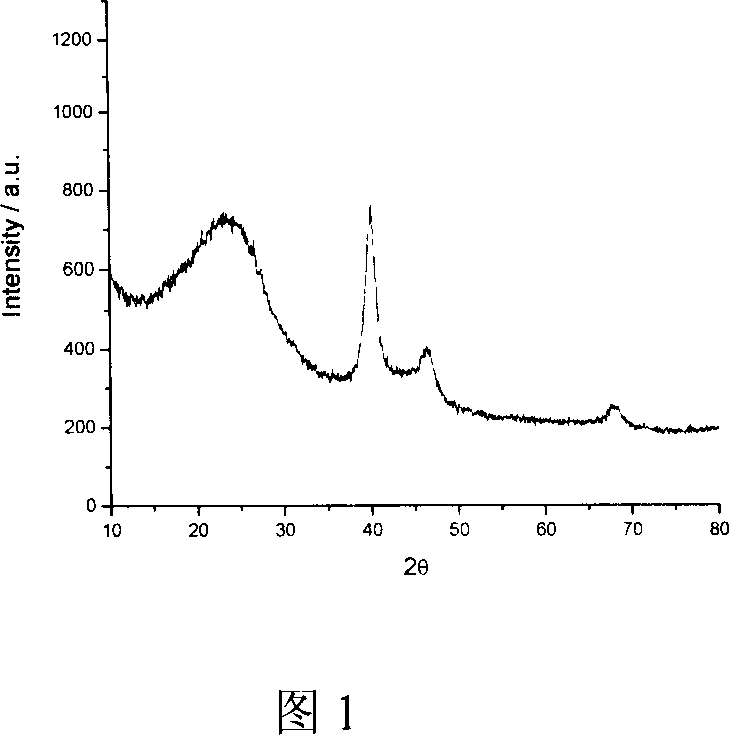

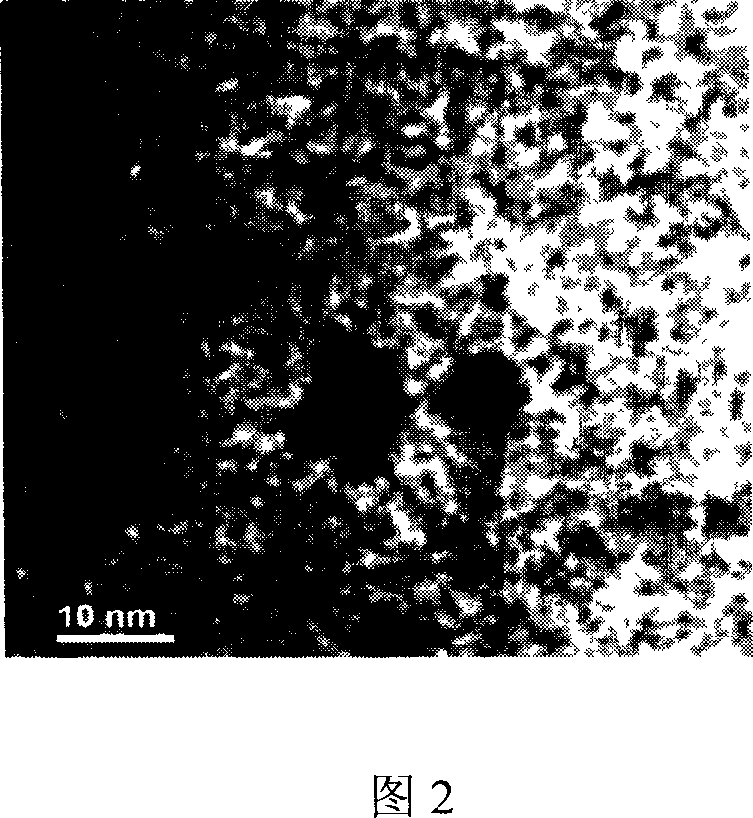

Method for preparing loading type nano Pd/C catalyst from colloidal solution

A colloidal solution and catalyst technology, applied in the field of catalysis, can solve problems such as short service life, poor stability of supported nano-palladium catalyst, complicated preparation process, etc., and achieve the effects of reducing production costs, avoiding organic pollution, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 0.1673gPdCl 2 After adding 10ml of water, add 0.6178g of concentrated hydrochloric acid, and dissolve it completely under ultrasound in a water bath at 50°C. After dissolving, add it into 150mL water containing 0.0534g of Brij35 and 0.0601g of Tween20, and add 1.5g / L NaBH dropwise 4 75mL aqueous solution, the orange solution quickly turned black to obtain a palladium colloidal solution, then added 2g of activated carbon and stirred for 1h, filtered, fully washed with water, and rinsed with THF to obtain 5% Pd / C.

Embodiment 2

[0021] Take by weighing the catalyst 0.25g that makes in the embodiment 1, join in the autoclave of 70ml, then add respectively reaction substrate o-nitrochlorobenzene, m-nitrochlorobenzene and p-nitrochlorobenzene 3.0g, solvent THF30ml, Seal the kettle, check for leaks, replace the air with nitrogen for 3 times, then replace the nitrogen with hydrogen for 3 times, start heating, when the temperature reaches 80°C, pressurize to 2.5MPa, and the reaction time is 1 hour, repeat the reaction operation, the reaction As a result, all 100% conversion of o-nitrochlorobenzene, m-nitrochlorobenzene and p-nitrochlorobenzene from the second time, the selectivity of o-nitroaniline, m-nitroaniline and p-nitroaniline is more than 99.7%. And after the catalyst is recycled for 40 times, the activity does not decrease significantly.

Embodiment 3

[0023] Take by weighing the catalyst 0.2g that makes in the embodiment 1, join in the autoclave of 70ml, add reaction substrate α-olefin polymer 8g, solvent cyclohexane 15ml, solution color is brownish yellow, seal kettle, check for leaks, Replace the air with nitrogen for 3 times, then replace the nitrogen with hydrogen for 3 times, start heating, when the temperature reaches 160°C, pressurize to 3.0MPa, after 2 hours of reaction, the brownish yellow color of the solution fades and turns into water white.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com