Method for preparing highly disperse supported noble metal nanoparticles

A nanoparticle, precious metal technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. The effect of avoiding organic pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

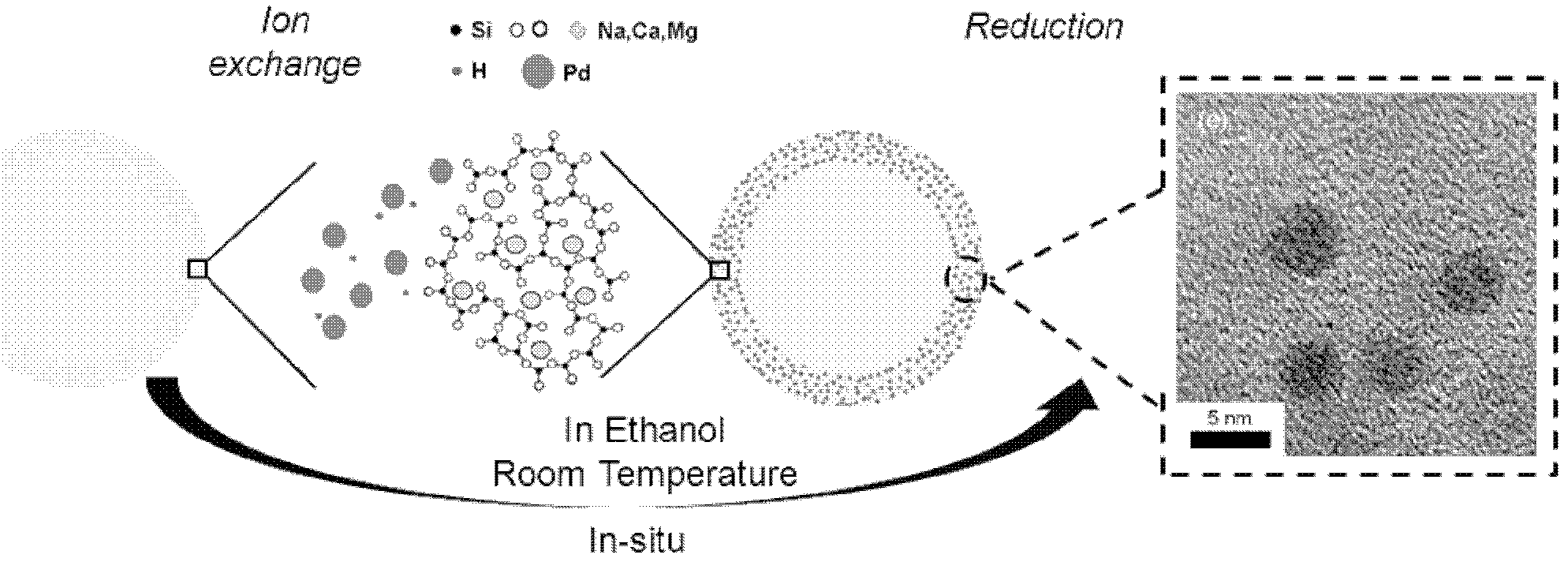

Embodiment 1

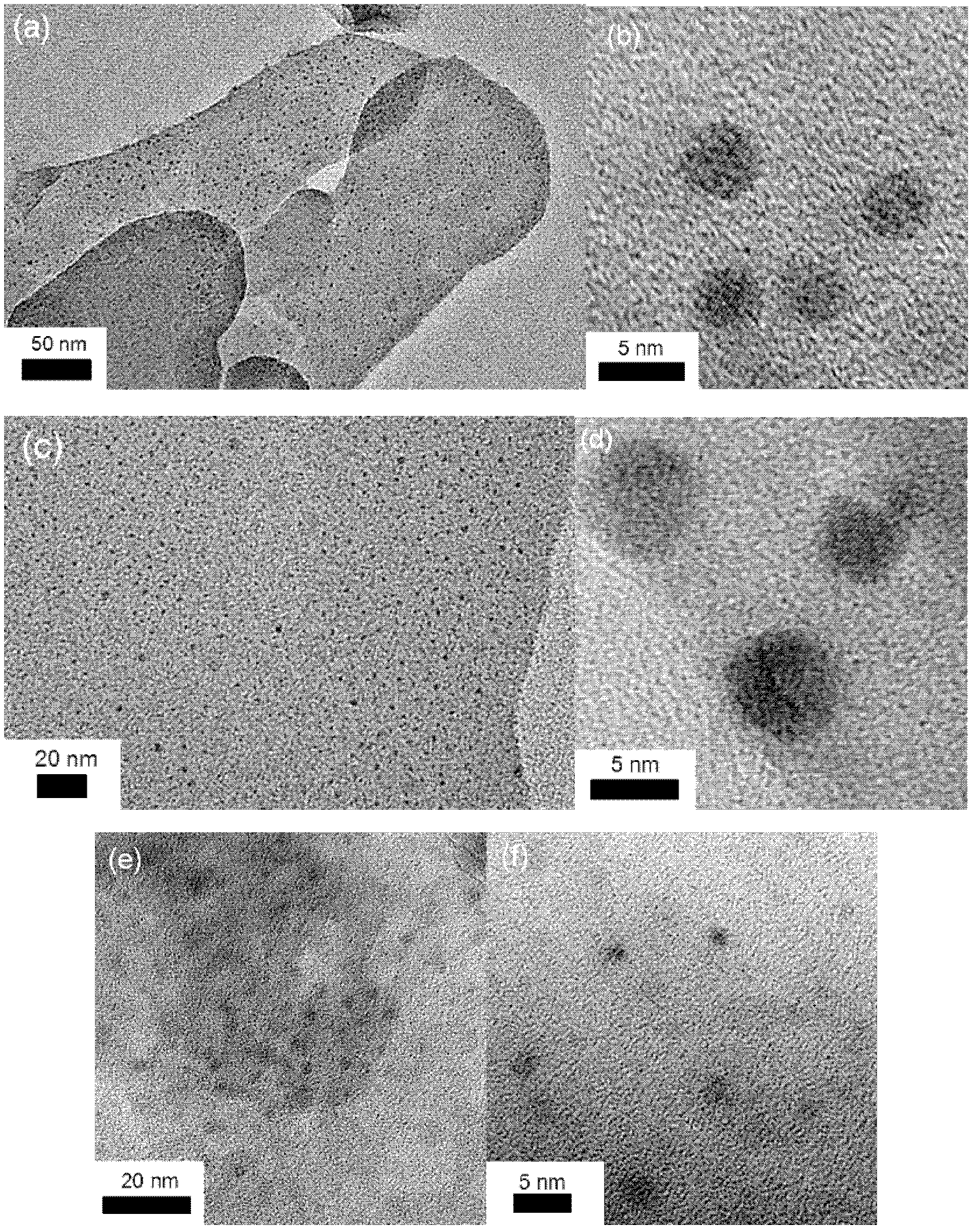

[0024] Take 1.5 g of porous glass microspheres with a core-shell structure particle size of 95-105 μm etched by subcritical water (at a temperature of 300° C. and a pressure of 10 MPa) and mix them with palladium chloride-ethanol solution with an initial concentration of 100 ppm. And stirred in a constant temperature water bath at 20°C for 24h. The color of the porous glass microspheres gradually changed from white to gray. After the adsorption reached equilibrium, the glass microspheres loaded with nano-palladium were taken out and washed 5 times with dehydrated ethanol to remove the ions on the surface of the material. Then place it in an oven and dry to obtain loaded palladium nanoparticles. figure 2 (a) and (b) are transmission photographs of samples obtained in this example.

Embodiment 2

[0026] Take 3.0 g of porous glass microspheres with a core-shell structure particle size of 95-105 μm etched by subcritical water (at a temperature of 300° C. and at a pressure of 10 MPa) and mix them with a silver nitrate-ethanol solution with an initial concentration of 600 ppm, and Stir in a constant temperature water bath at 30°C for 30h. The color of the glass microspheres gradually changed from white to gray. After the adsorption reached equilibrium, the glass microspheres loaded with nano-silver were taken out and washed 4 times with dehydrated ethanol to remove the ions on the surface of the material. Then place in an oven and dry to obtain loaded silver nanoparticles. figure 2 (c) and (d) are transmission photos of the samples obtained in this example.

Embodiment 3

[0028] Take 1.0 g of porous glass microspheres with a core-shell structure particle size of 95-105 μm etched by subcritical water (at a temperature of 300° C. and a pressure of 10 MPa) and mix them with gold chloride-ethanol solution with an initial concentration of 50 ppm. And stirred in a constant temperature water bath at 50°C for 5h. The color of the glass microspheres gradually changed from white to pink. After the adsorption reached equilibrium, the glass microspheres loaded with nano-palladium were taken out and washed with dehydrated ethanol 10 times to remove ions on the surface of the material. Then place it in an oven and dry to obtain supported gold nanoparticles. figure 2 (e) and (f) are transmission photographs of samples obtained in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com