Bombax cotton phase-change material production method

A manufacturing method and technology of phase change materials, which are applied in the directions of heat exchange materials, chemical instruments and methods, textiles and papermaking, etc., can solve the problems that the adjustment temperature range cannot meet the actual needs, the appearance of the fabric is sticky, and the practical value is poor, etc. Achieve the effect of alleviating environmental temperature changes, comfortable living environment, and saving cooling and heating energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

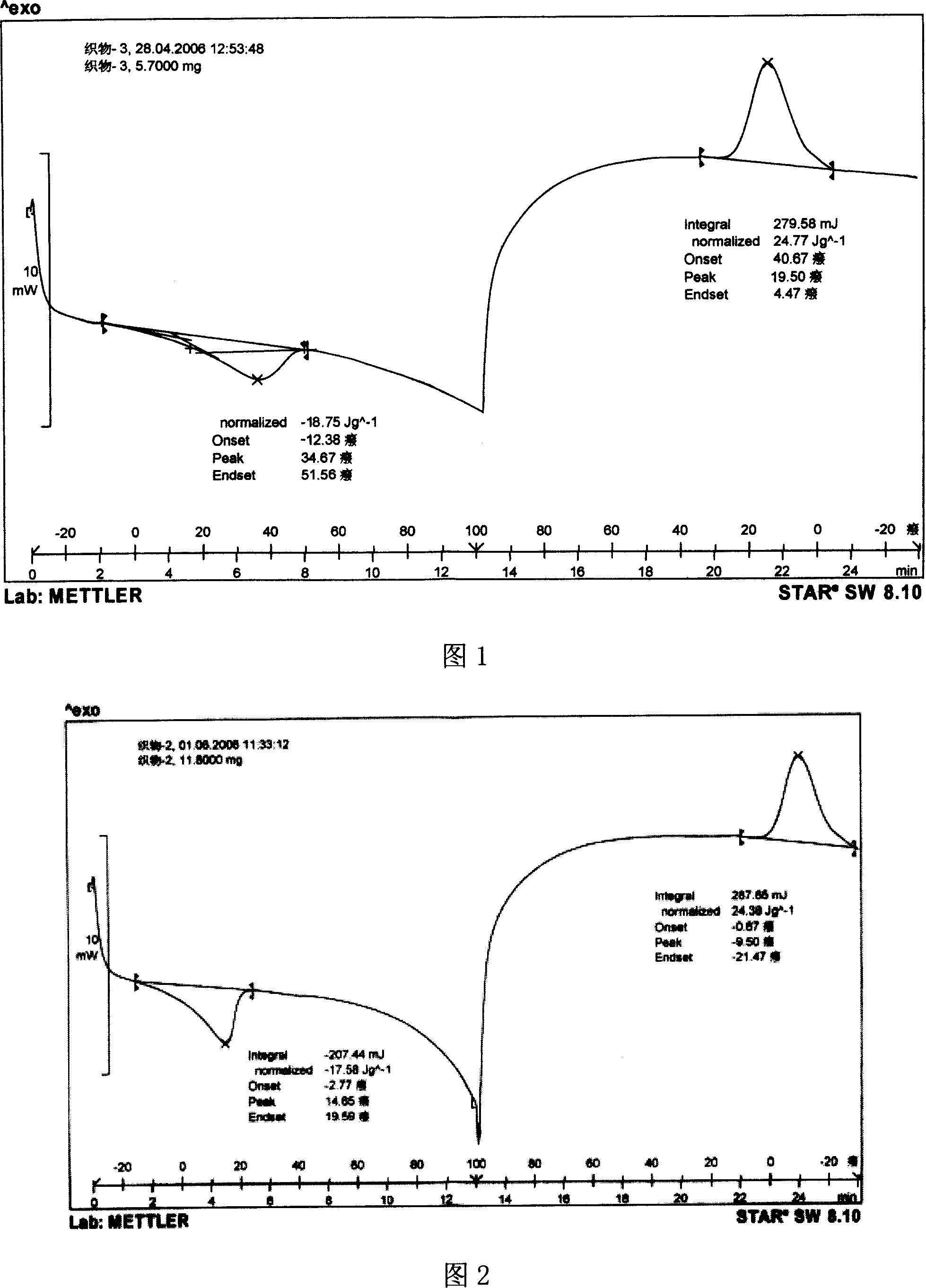

[0035] 50% PEG-1000, 25% 2D resin, 3% MgCl 2 ·6H 2 O / citric acid mixture (molar ratio 15:1) and 3% NaCl were formulated as a phase-change finishing agent, kapok / cotton (50 / 50) blended knitted fabrics were dipped in the finishing agent for two hours, and then untreated Extrude the excess finishing agent that forms cross-linking, pre-baking at 80°C for 7 minutes, baking at 140°C for 3 minutes, soaping at 60°C for 10 minutes with a bath ratio of 2g / L, and then rinsing with water Clean, dry at 100°C, and finally use the PyrisIDSC differential tracing calorimeter of the Perkin-Elme Company of the United States to detect the absorption and exothermic properties of the sample, that is, the DSC curve, see Figure 1.

Embodiment 2

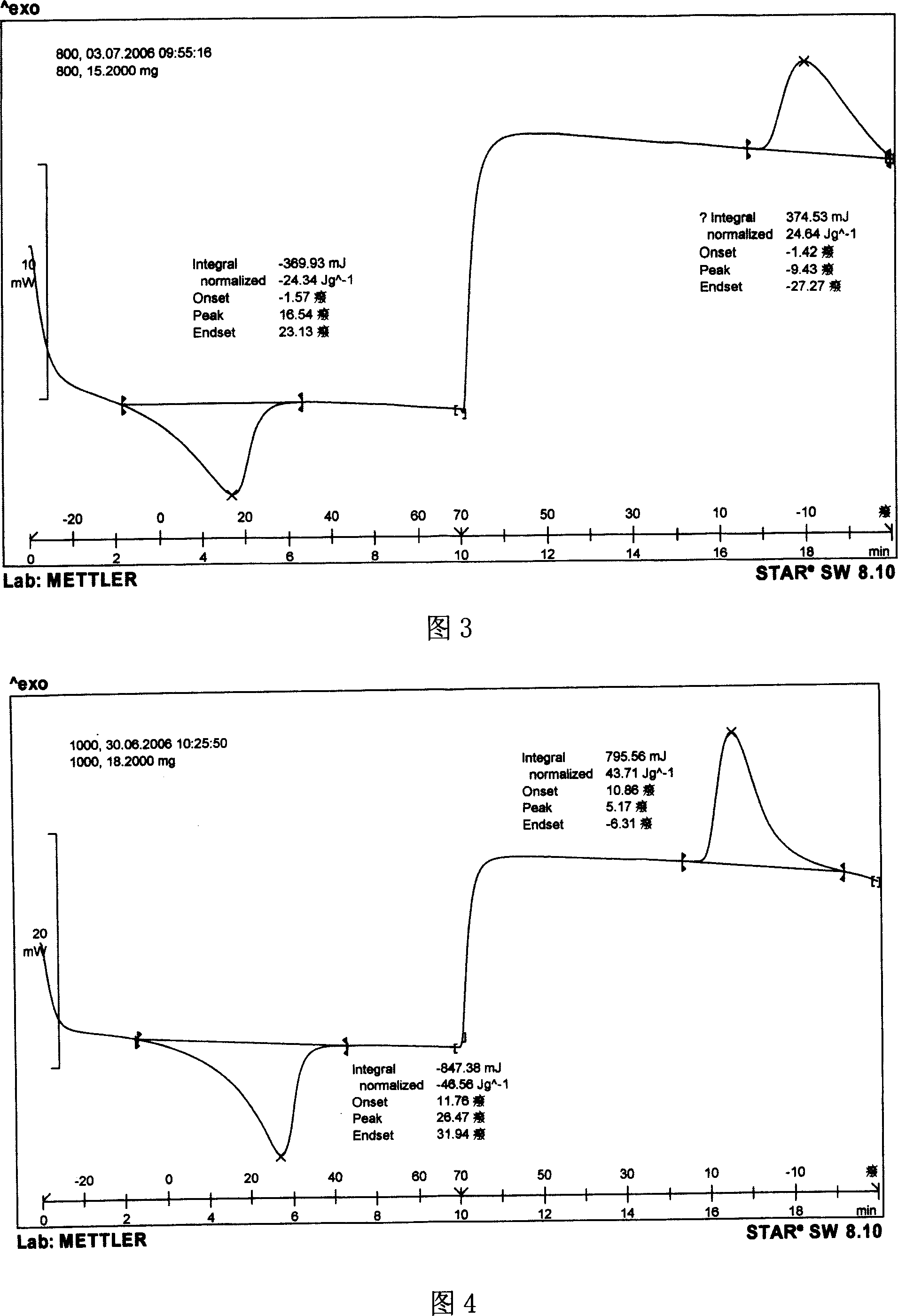

[0037] 20% PEG-600, 15% 2D resin, 2% MgCl 2 ·6H 2 O / citric acid (molar ratio 12: 1), 9% NaCl is made into phase-change finishing agent, impregnated kapok blended fabric (48% kapok, 48% cotton, spandex 4%) for 1 hour, and then rolled with conventional finishing machinery Squeeze out the excess finishing agent that has not formed cross-linking with a stick, pre-bake at 40°C for 10 minutes, bake at 160°C for 1 minute, and soap at 60°C for 20 minutes with a bath ratio of 2g / L. Then rinse with clean water, dry at 100°C, and finally use the PyrisIDSC differential tracing calorimeter of the American Perkin-Elme company to test the sample to obtain the DSC curve, see Figure 2.

Embodiment 3

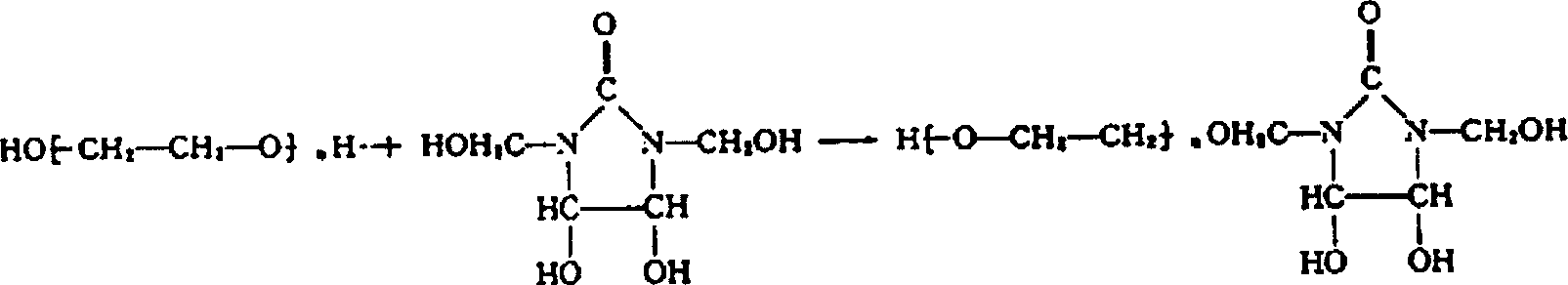

[0039] 80% PEG-800, 20% 2D resin, 8% MgCl 2 ·6H 2 O / citric acid (molar ratio 10:1), 5% K 2 SO 4 Make phase change finishing agent, impregnate kapok fiber for 5 hours, squeeze out excess uncrosslinked finishing agent with equipment, pre-bake at 100°C for 3 minutes, bake at 80°C for 5 minutes, use 2g / L Soap at 60°C for 20 minutes, then rinse with clean water, dry at 100°C, and finally test the DSC curve of the sample with a PyrisIDSC differential tracing calorimeter from the American Perkin-Elme Company, see Figure 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com