Multifunctional macromolecule filter material and preparation method thereof

A filter material and polymer technology, applied in the field of multifunctional polymer filter material and its preparation, can solve the problems of high finished product price, reduced output, and increased cost difference of filter cloth, and achieve the effect of low cost and high cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the present invention is as follows:

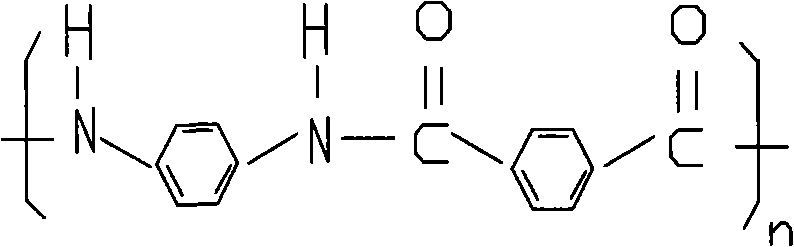

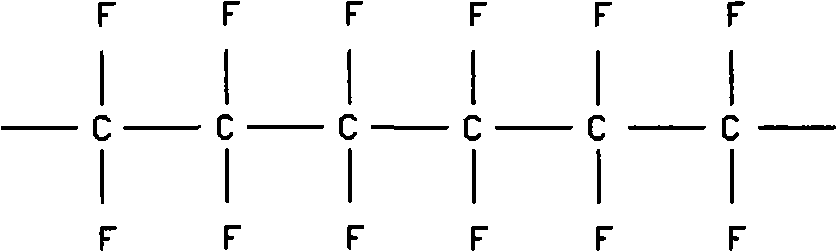

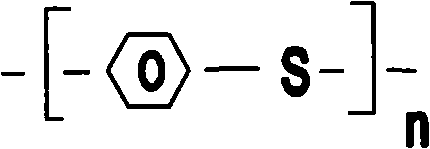

[0018] Needle-punching the mixed fiber and the base cloth, and then impregnated with liquid, singeing, and calendering to shape the finished product, wherein the mixed fiber includes glass fiber with a content of 70% to 85%, and the rest is aramid fiber, polyester One or more of the eight types of tetrafluoroethylene fiber, polyphenylene sulfide fiber, poly-p-phenylene benzobisoxazole (PBO) fiber, para-aramid fiber, ceramic fiber, stainless steel fiber, and copper fiber. Aramid fiber, polytetrafluoroethylene fiber, and polyphenylene sulfide fiber have the advantages of high temperature resistance and strong corrosion resistance, but the prices of the three are relatively high, and glass fiber is the main choice of raw materials.

Embodiment 1

[0020] 85% of glass fiber and 15% of polyphenylene sulfide fiber are used as the proportion, and then the polytetrafluoroethylene fiber woven fabric is used as the base fabric. In order to enhance the corrosion resistance and air permeability of the finished product, the ptfe film is covered on the finished product after being melted. At the same time, the ptfe film can also trap fine dust. Here, 15% polyphenylene sulfide fiber can be used with 15% aramid fiber, polytetrafluoroethylene fiber, poly-p-phenylene benzobisoxazole (PBO) fiber, para-aramid fiber, ceramic fiber, stainless steel fiber and Any one of the copper fibers can be substituted. The performance of the finished product will vary depending on the selected components.

[0021] The glass fibers are alkali-free glass fibers. Glass fiber has low cost and high strength, and selecting glass fiber as the main raw material of the method can minimize the production cost. However, due to the low cohesive force of glass f...

Embodiment 2

[0026] With 75% glass fiber, 24% aramid fiber, and 1% copper fiber as the proportion, the glass fiber woven fabric is used as the base fabric. After being needled by acupuncture equipment, it is impregnated, singeed, calendered and finalized. Here, replacing 1% copper fiber with 1% carbon fiber or 1% stainless steel fiber can also make the finished product have anti-static function. In addition, 24% aramid fiber can use any one of 24% polytetrafluoroethylene fiber, polyphenylene sulfide fiber, poly-p-phenylene benzobisoxazole (PBO) fiber, para-aramid fiber, ceramic fiber Instead, refer to Embodiment 1 for the remaining content of Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com