Radiation refrigeration composite-photon-structure thin membrane and preparation method thereof

A photonic structure, radiation cooling technology, applied in synthetic fibers, fiber types, textiles and papermaking, etc., can solve the problems of difficult to achieve large-scale production, complicated and expensive coating process, limited popularization and application, etc., to achieve excellent radiation cooling effect, Low angle dependence, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

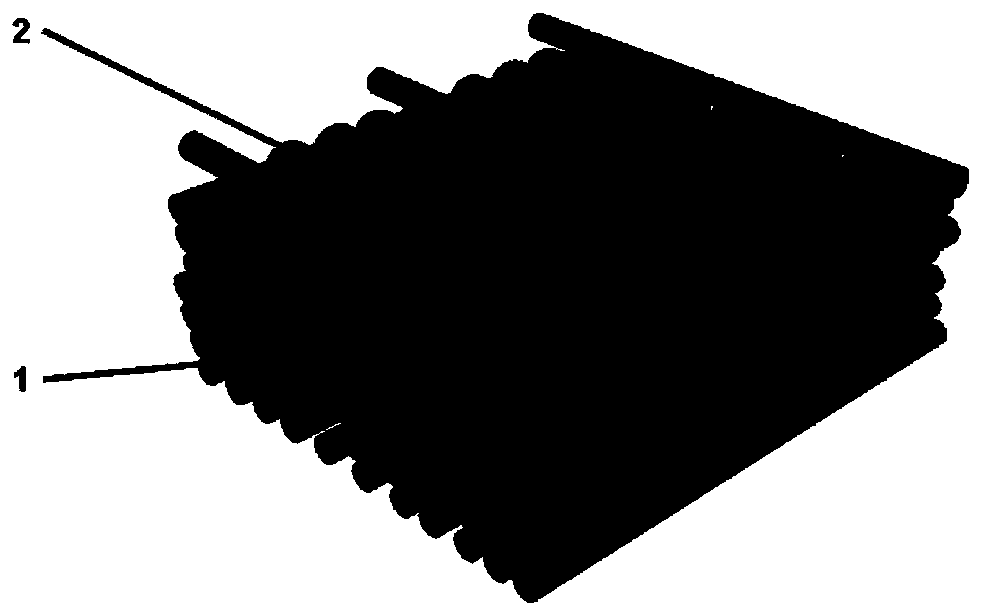

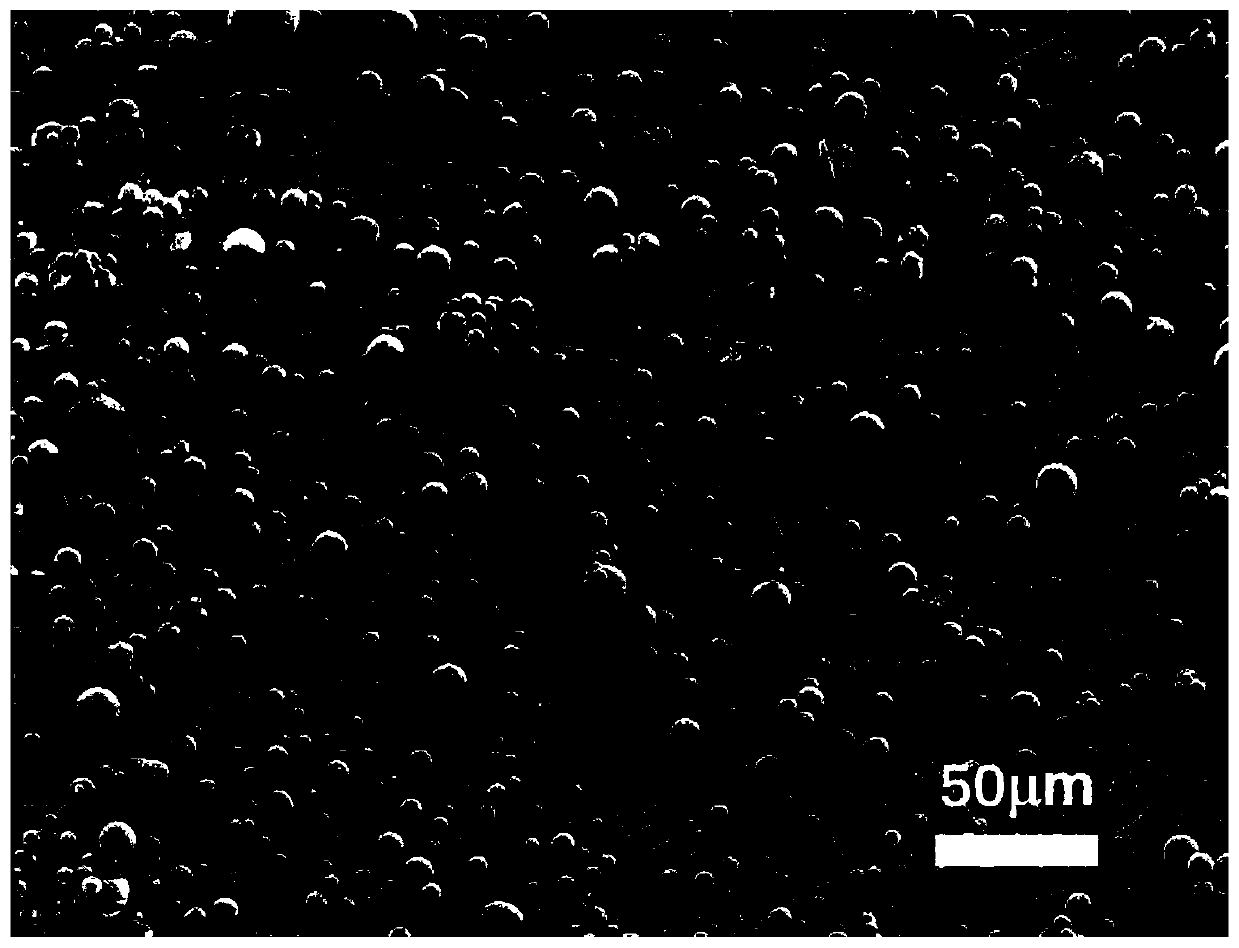

[0027] First configure the electrospinning solution, dissolve polyvinylidene fluoride in N,N-dimethylformamide, stir it magnetically for 1 hour, prepare a polyvinylidene fluoride sol with a mass fraction of 3% for use, and then add orthosilicic acid Tetraethyl ester, ethanol, and 0.01mol / L hydrochloric acid were mixed in a volume ratio of 10:10:1.6 and magnetically stirred to obtain a tetraethyl orthosilicate solution, and the prepared polyvinylidene fluoride sol and tetraethyl orthosilicate solution Mix at a volume ratio of 8:1, stir magnetically in a water bath at 40°C for 1 hour, and configure it as an electrospinning solution; set the positive spinning voltage to 20KV, negative voltage to -1KV, and the spinning solution flow rate to 1mL / L to pass through the electrostatic spinning method. A polyvinylidene fluoride / tetraethyl orthosilicate mixture fiber layer was obtained. Add silica microspheres with an average diameter of about 10 μm to ethanol to prepare a 1 mg / mL disper...

Embodiment 2

[0030]First configure the electrospinning solution, dissolve polyvinylidene fluoride in N,N-dimethylformamide, stir it magnetically for 1 hour, prepare a polyvinylidene fluoride sol with a mass fraction of 3% for use, and then add orthosilicic acid Tetraethyl ester, ethanol, and 0.1mol / L hydrochloric acid were mixed at a volume ratio of 10:10:3 and magnetically stirred evenly to obtain tetraethyl orthosilicate solution, and the prepared polyvinylidene fluoride sol and tetraethyl orthosilicate solution Mix at a volume ratio of 8:1, stir magnetically in a water bath at 60°C for 1 hour, and prepare an electrospinning solution; set the positive spinning voltage to 20KV, negative voltage to -1KV, and the flow rate of the spinning solution to 2mL / L to pass through the electrospinning method. A polyvinylidene fluoride / tetraethyl orthosilicate mixture fiber layer was obtained. Add silicon dioxide microspheres with an average diameter of about 10 μm to ethanol to prepare a 1 mg / mL disp...

Embodiment 3

[0033] First configure the electrospinning solution, dissolve polyvinylpyrrolidone in N,N-dimethylformamide, stir it magnetically for 1 hour, prepare a polyvinylpyrrolidone sol with a mass fraction of 3% for use, and then dissolve tetraethylorthosilicate Esters, ethanol, and 0.01mol / L hydrochloric acid were mixed with a volume ratio of 8:8:3 and magnetically stirred to obtain a tetraethyl orthosilicate solution, and the prepared polyvinylpyrrolidone sol and tetraethyl orthosilicate solution were mixed at a ratio of 2: Mix at a volume ratio of 1, stir magnetically in a water bath at 70°C for 1 hour, and prepare an electrospinning solution; set a positive spinning voltage of 20KV, a negative voltage of -1KV, and a spinning solution flow rate of 1mL / L to obtain polyethylene by electrospinning Pyrrolidone / tetraethylorthosilicate mixture fibrous layer. Add silicon dioxide microspheres with an average diameter of about 10 μm to ethanol to prepare a 1 mg / mL dispersion, and ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com