A kind of radiative cooling composite photonic structure thin film and its preparation method

A technology of photon structure and radiation refrigeration, which is applied in the fields of synthetic fiber, fiber processing, textiles and papermaking, etc., can solve the problems of complex and expensive coating process, difficulty in large-scale production, and limited popularization and application, and achieve excellent radiation refrigeration effect, Low Angle Dependency, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

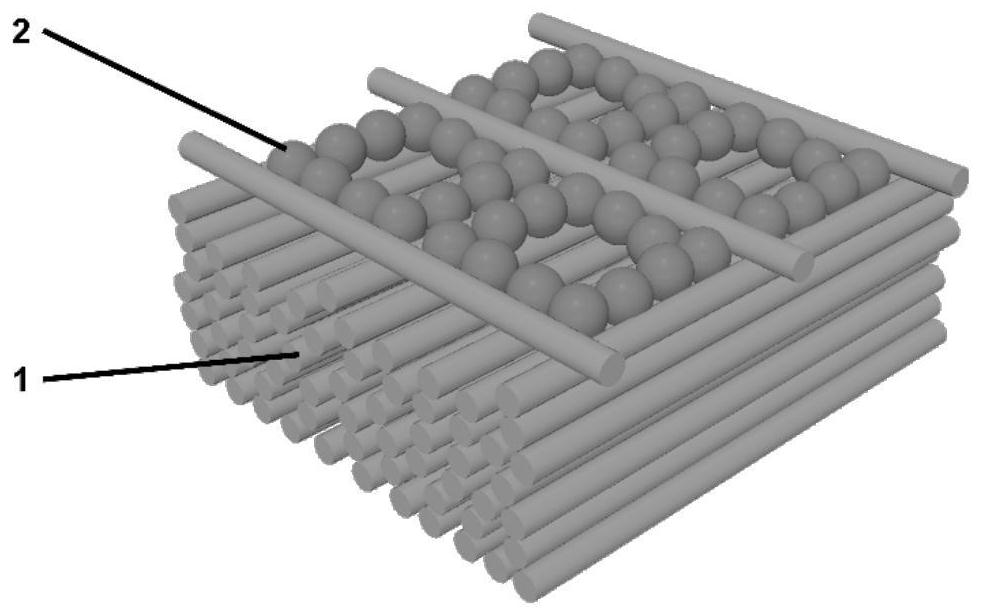

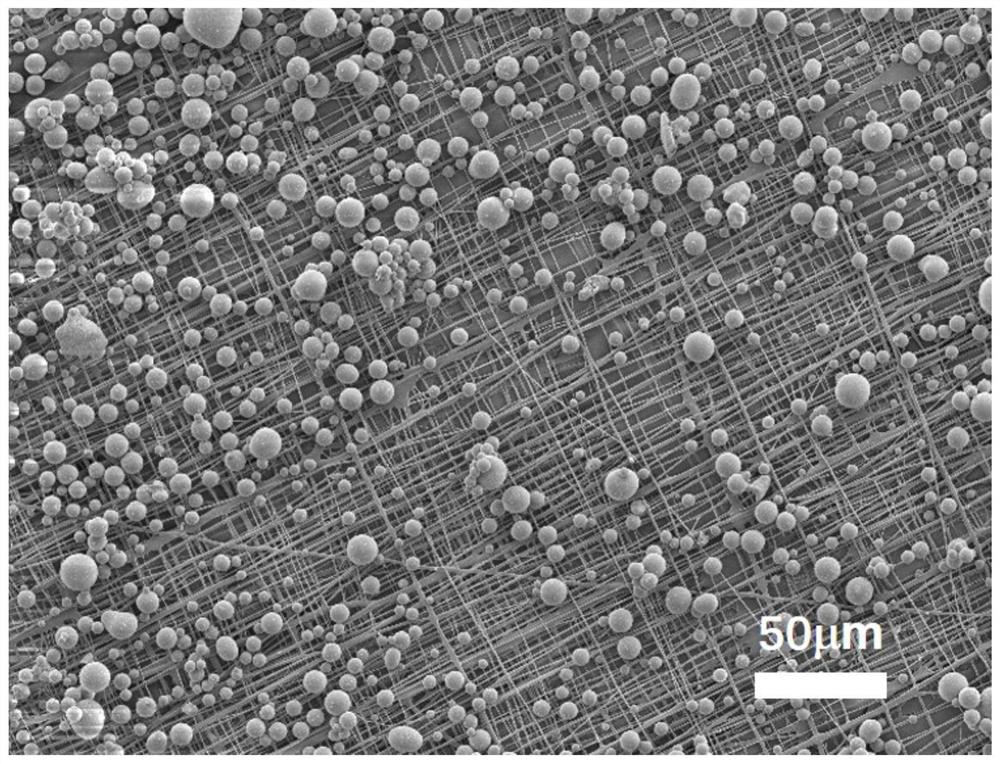

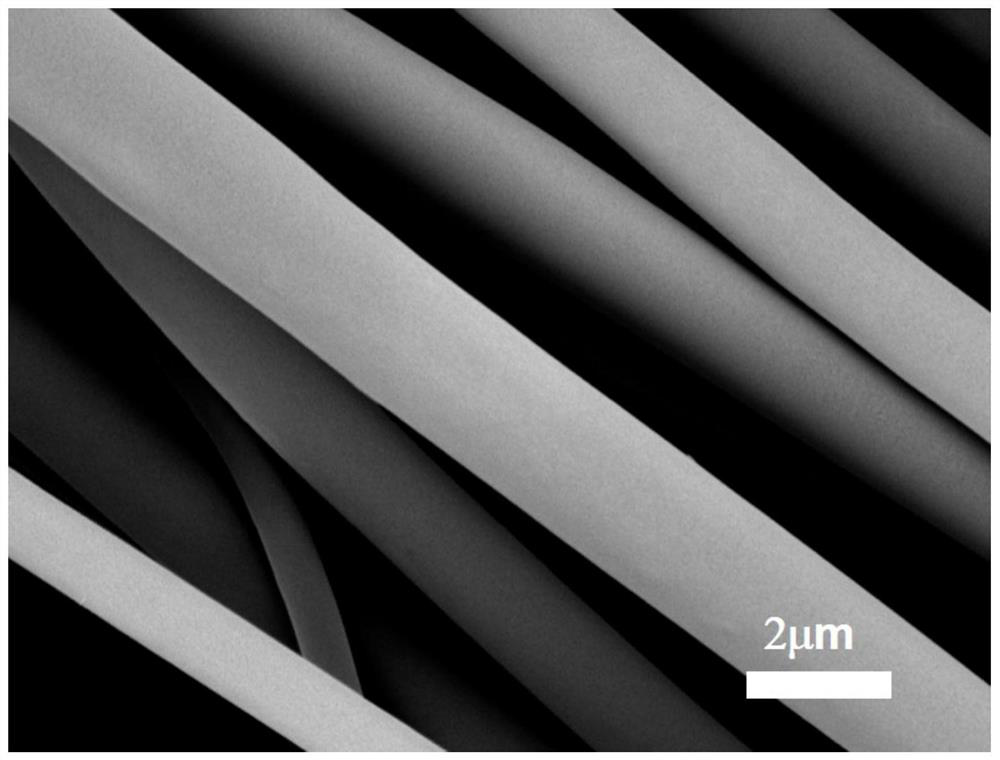

[0027] First configure the electrospinning solution, dissolve polyvinylidene fluoride in N,N-dimethylformamide, stir it magnetically for 1 hour, prepare a polyvinylidene fluoride sol with a mass fraction of 3% for use, and then add orthosilicic acid Tetraethyl ester, ethanol, and 0.01mol / L hydrochloric acid were mixed in a volume ratio of 10:10:1.6 and magnetically stirred to obtain a tetraethyl orthosilicate solution, and the prepared polyvinylidene fluoride sol and tetraethyl orthosilicate solution Mix at a volume ratio of 8:1, stir magnetically in a water bath at 40°C for 1 hour, and configure it as an electrospinning solution; set the positive spinning voltage to 20KV, negative voltage to -1KV, and the spinning solution flow rate to 1mL / L to pass through the electrostatic spinning method. A polyvinylidene fluoride / tetraethyl orthosilicate mixture fiber layer was obtained. Add silica microspheres with an average diameter of about 10 μm to ethanol to prepare a 1 mg / mL disper...

Embodiment 2

[0030]First configure the electrospinning solution, dissolve polyvinylidene fluoride in N,N-dimethylformamide, stir it magnetically for 1 hour, prepare a polyvinylidene fluoride sol with a mass fraction of 3% for use, and then add orthosilicic acid Tetraethyl ester, ethanol, and 0.1mol / L hydrochloric acid were mixed at a volume ratio of 10:10:3 and magnetically stirred evenly to obtain tetraethyl orthosilicate solution, and the prepared polyvinylidene fluoride sol and tetraethyl orthosilicate solution Mix at a volume ratio of 8:1, stir magnetically in a water bath at 60°C for 1 hour, and prepare an electrospinning solution; set the positive spinning voltage to 20KV, negative voltage to -1KV, and the flow rate of the spinning solution to 2mL / L to pass through the electrospinning method. A polyvinylidene fluoride / tetraethyl orthosilicate mixture fiber layer was obtained. Add silicon dioxide microspheres with an average diameter of about 10 μm to ethanol to prepare a 1 mg / mL disp...

Embodiment 3

[0033] First configure the electrospinning solution, dissolve polyvinylpyrrolidone in N,N-dimethylformamide, stir it magnetically for 1 hour, prepare a polyvinylpyrrolidone sol with a mass fraction of 3% for use, and then dissolve tetraethylorthosilicate Esters, ethanol, and 0.01mol / L hydrochloric acid were mixed with a volume ratio of 8:8:3 and magnetically stirred to obtain a tetraethyl orthosilicate solution, and the prepared polyvinylpyrrolidone sol and tetraethyl orthosilicate solution were mixed at a ratio of 2: Mix at a volume ratio of 1, stir magnetically in a water bath at 70°C for 1 hour, and prepare an electrospinning solution; set a positive spinning voltage of 20KV, a negative voltage of -1KV, and a spinning solution flow rate of 1mL / L to obtain polyethylene by electrospinning Pyrrolidone / tetraethylorthosilicate mixture fibrous layer. Add silicon dioxide microspheres with an average diameter of about 10 μm to ethanol to prepare a 1 mg / mL dispersion, and ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com