Method for producing film with high visible light absorption and high infrared radiation performances

A technology of infrared radiation and manufacturing method, which is applied in the fields of visible light absorption and infrared radiation, can solve problems such as complex manufacturing process, unavailable application, and difficult molding, and achieve the effects of simple processing technology, improved visible light absorption performance, and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

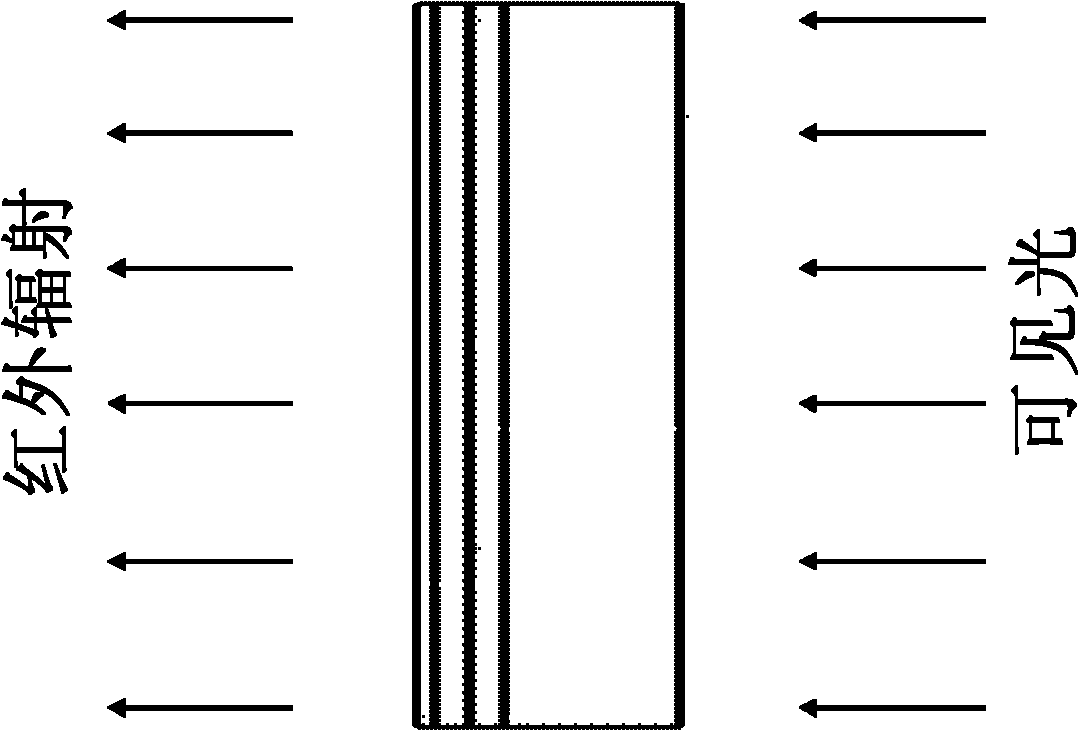

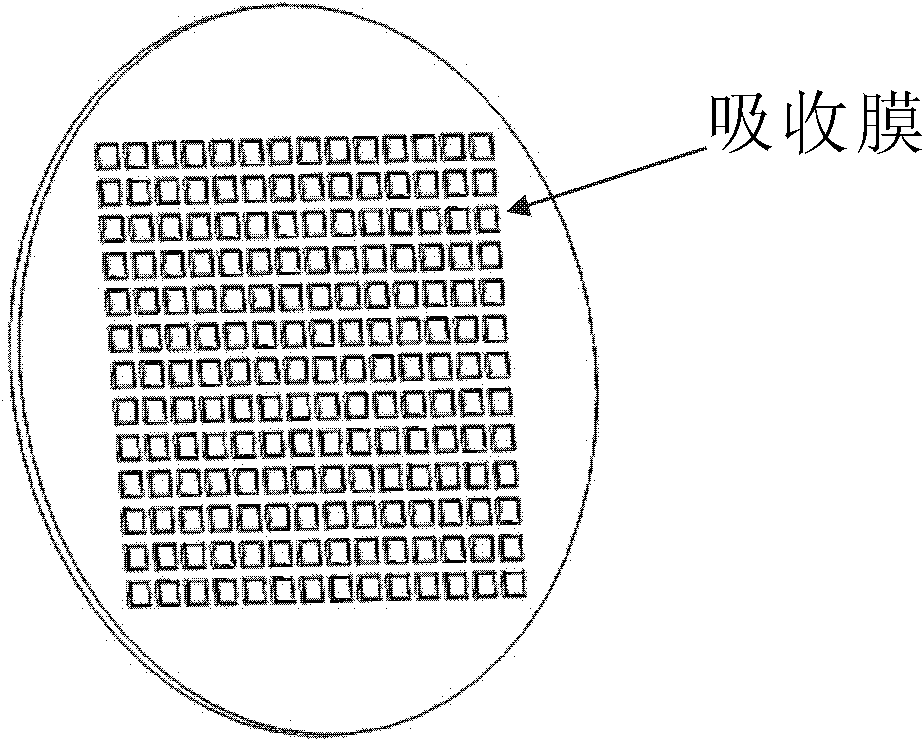

[0018] The invention proposes a method for manufacturing a thin film with high visible light absorption and high infrared radiation, which is manufactured by micro-machining technology, the absorbing layer of the thin film absorbs the incident visible light, and at the same time, the energy of visible light is transmitted to the radiation layer with high infrared radiation performance Radiate outward to complete the conversion from visible light to infrared light.

[0019] The present invention will be described in detail below by taking a visible light-to-infrared conversion chip as an example with reference to the accompanying drawings.

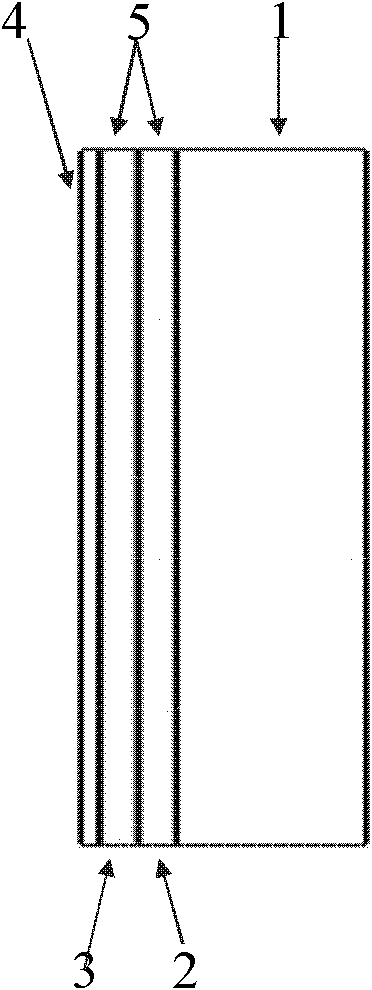

[0020] figure 1 Schematic diagram of a cross-section of a thin film with high visible light absorption and high infrared radiation including the substrate. As shown in the figure, it includes a substrate 1 , an adhesive layer 2 , a carbonized layer 3 and a radiation layer 4 . Wherein the adhesive layer 2 and the carbonized layer 3 combine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com