Method for inhibiting low-temperature denitration catalyst poisoning caused by SO2

A low-temperature denitrification and catalyst technology, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, can solve problems such as little consideration of impact, and achieve the effects of simple method, extended service life, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

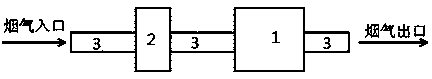

Image

Examples

Embodiment 1

[0018] MnO x -CuO / TiO 2 -CNTs are low-temperature denitrification catalysts, with NH 3 and NO concentrations were 800ppm, O 2 Concentration is 3%, the rest are N 2 The mixed gas is used as the simulated flue gas, and the gas injector is used to inject oxygen into the simulated flue gas, so that 50% of the NO in the flue gas is oxidized to NO 2 , and then the above containing NO 2 The flue gas takes 8000h -1 The air velocity is passed into the SCR denitrification facility, and the flue gas is denitrified and purified by passing through the above-mentioned low-temperature denitrification catalyst at 100°C, 150°C and 200°C respectively.

[0019] The denitrification test shows that the denitrification efficiencies are 29%, 48% and 80% at 100°C, 150°C and 200°C, respectively.

Embodiment 2

[0021] Same as Example 1, the difference is that SO is added to the simulated flue gas 2 gas, SO 2 The concentration is 400ppm, and other conditions remain unchanged.

[0022] In the denitrification test, it was measured that the denitrification efficiencies were 26%, 66% and 87% at 100°C, 150°C and 200°C, respectively, and remained unchanged for at least 40 hours; comparative example 1 shows that the addition of SO 2 After that, no low temperature denitrification catalyst poisoning phenomenon occurred.

Embodiment 3

[0024] The low-temperature denitrification catalyst is the same as in Example 1, and the simulated flue gas is the same as in Example 2. The simulated flue gas is directly treated with 8000h -1 The space velocity is passed into the SCR denitrification facility, and passes through the above-mentioned low-temperature denitrification catalyst at 100°C, 150°C and 200°C respectively.

[0025] In the denitrification test, it was measured that at 100°C, 150°C and 200°C, the denitrification efficiency dropped to 4%, 7% and 12% respectively. Comparative Example 2 illustrates that part of NO is oxidized to NO without spraying oxygen into simulated flue gas. 2 , the low-temperature denitrification catalyst immediately produces SO 2 poisoning, leading to a decrease in denitrification efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com