Catalyst for ethyne hydrochlorination for synthesis of chloroethylene and preparation method thereof

A technology for synthesizing vinyl chloride and a catalyst by hydrochlorination of acetylene, which is applied in the field of catalysis, can solve the problems such as the use of catalysts for the hydrochlorination of acetylene, which has not yet been used, and achieve the effects of simple production and preparation method, slowing down poisoning, and few side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

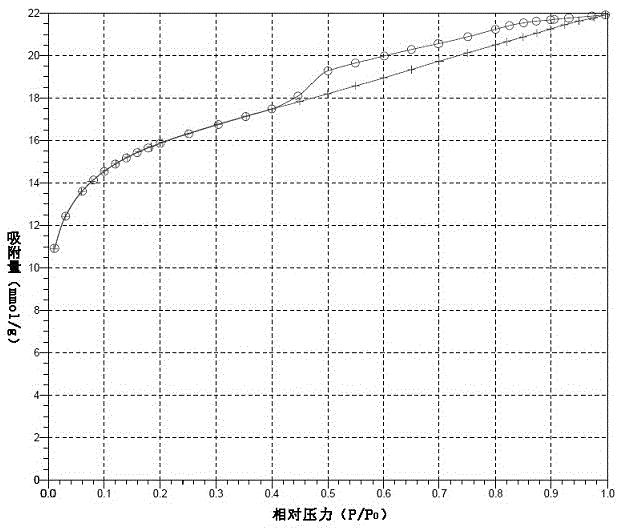

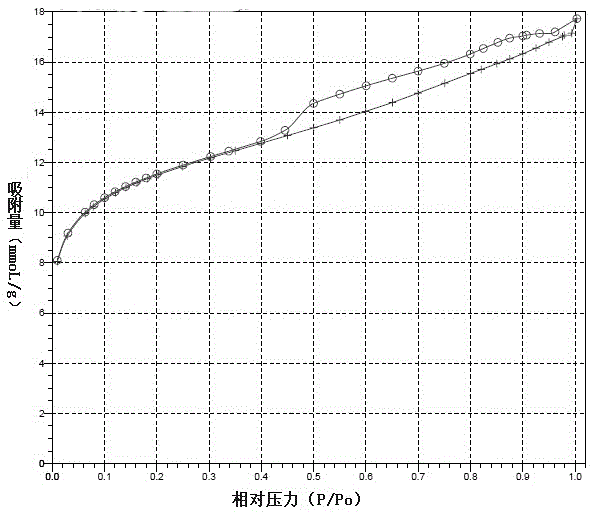

[0020] Weigh 2.65g of copper chloride dihydrate, weigh 2g of tartaric acid, add 30ml of deionized water, stir to dissolve, adjust the pH value to 2 with hydrochloric acid, and control the temperature of the impregnation solution to 40°C by heating with an electric heating mantle. Add 15g of dry activated carbon, impregnate at room temperature for 8h, dry at 105°C for 8h, and roast in a nitrogen atmosphere in a tube furnace for 2h to obtain the acetylene hydrochlorination catalyst, and the conversion rate of acetylene is 100%. Table 1 and figure 1 , figure 2 comparison.

Embodiment 2

[0022] Weigh 1.58g of bismuth chloride and 2g of oxalic acid, add 30ml of deionized water, stir to dissolve, adjust the pH value to 1.5 with hydrochloric acid, and control the temperature of the impregnation solution to 35°C by heating with an electric heating mantle. Add 15g of dry activated carbon, impregnate at room temperature for 6h, oven dry at 110°C for 9h, and roast in a tube furnace for 1.5h in a nitrogen atmosphere to obtain an acetylene hydrochlorination catalyst with an acetylene conversion rate of 90%. The content of bismuth element in the catalyst was characterized and analyzed by microwave digestion and atomic absorption of the catalyst prepared in this case and the catalyst without the addition of competitive adsorbent oxalic acid, as shown in Table 2.

Embodiment 3

[0024] Weigh 2g of barium nitrate and 2g of citric acid, add 30ml of deionized water, stir to dissolve, adjust the pH value to 1.5 with hydrochloric acid, and control the temperature of the impregnating solution to 50°C by heating with an electric heating mantle. Add 15 g of dry activated carbon, soak at room temperature for 7 hours, oven dry at 110°C for 6.5 hours, and roast in a tube furnace for 3 hours in a nitrogen atmosphere to obtain an acetylene hydrochlorination catalyst with an acetylene conversion rate of 67%.

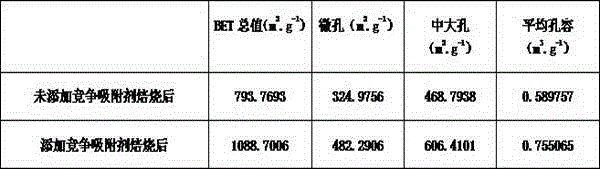

[0025] Table 1 BET comparison table before and after adding tartaric acid to samples

[0026]

[0027] Table 2 The difference of catalyst active component content before and after adding competitive adsorbent

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com