Movable cleaning and regenerating device and cleaning and regenerating method for SCR (selective catalytic reduction) denitration catalysts

A technology for denitrification catalysts and regeneration devices, applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of increasing additional costs for cleaning and regeneration, easily damaged catalysts, and many personnel required , to achieve good cleaning and regeneration effects, avoid transportation damage, and achieve high equipment integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

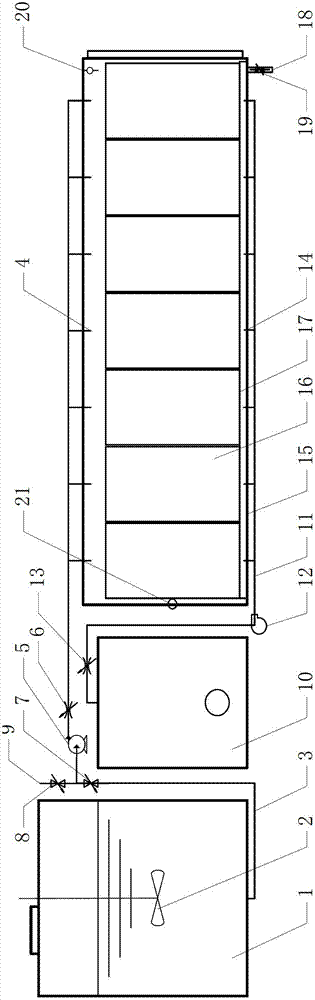

[0032] As shown in the drawings, this embodiment is a cleaning and regeneration method for a removable SCR denitration catalyst cleaning and regeneration device, the steps are as follows:

[0033] Step 1: Detection: Test the activity of the poisoned catalyst, and determine that the catalyst is deactivated by 80% or more, which is severe deactivation;

[0034] Step 2: Liquid preparation: Add oxalic acid solution, dispersant MF, ammonium metavanadate and ammonium metatungstate to the regeneration liquid container 1 to configure the regeneration liquid, and use an electric stirrer to stir for more than 10 minutes to obtain the regeneration liquid, in which the dispersant MF accounts for the regeneration liquid The weight percent of liquid is 1wt%, and the weight percent that ammonium metavanadate accounts for regeneration liquid is 10wt%, and the weight percent of ammonium paratungstate concentration accounts for regeneration liquid is 20wt%, and the pH value of regeneration liquid ...

Embodiment 2

[0044] As shown in the drawings, this embodiment is a cleaning and regeneration method for a removable SCR denitration catalyst cleaning and regeneration device, the steps are as follows:

[0045] Step 1: Detection: test the activity of the poisoned catalyst, and determine that the catalyst is 50%-80% deactivated, which is moderately deactivated;

[0046] Step 2: Liquid preparation: Add oxalic acid solution, dispersant MF, ammonium metavanadate and ammonium metatungstate to the regeneration liquid container 1 to configure the regeneration liquid, and use an electric stirrer to stir for more than 10 minutes to obtain the regeneration liquid, in which the dispersant MF accounts for the regeneration liquid The weight percent of liquid is 1wt%, and the weight percent that ammonium metavanadate accounts for regeneration liquid is 8wt%, and the weight percent of ammonium paratungstate concentration accounts for regeneration liquid is 18wt%, and the pH value of regeneration liquid is ...

Embodiment 3

[0056] As shown in the drawings, this embodiment is a cleaning and regeneration method for a removable SCR denitration catalyst cleaning and regeneration device, the steps are as follows:

[0057] Step 1: Detection: test the activity of the poisoned catalyst, and determine that the catalyst is deactivated by 50% or less, which is mild deactivation;

[0058] Step 2: Liquid preparation: Add oxalic acid solution, dispersant MF, ammonium metavanadate and ammonium metatungstate to the regeneration liquid container 1 to configure the regeneration liquid, and use an electric stirrer to stir for more than 10 minutes to obtain the regeneration liquid, in which the dispersant MF accounts for the regeneration liquid The weight percent of liquid is 1wt%, and the weight percentage that ammonium metavanadate accounts for regeneration liquid is 5wt%, and ammonium paratungstate concentration accounts for the weight percent of regeneration liquid is 15wt%, and the pH value of regeneration liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com