Application of polyacid intercalated hydrotalcite catalyst in preparing glyceryl triacetate

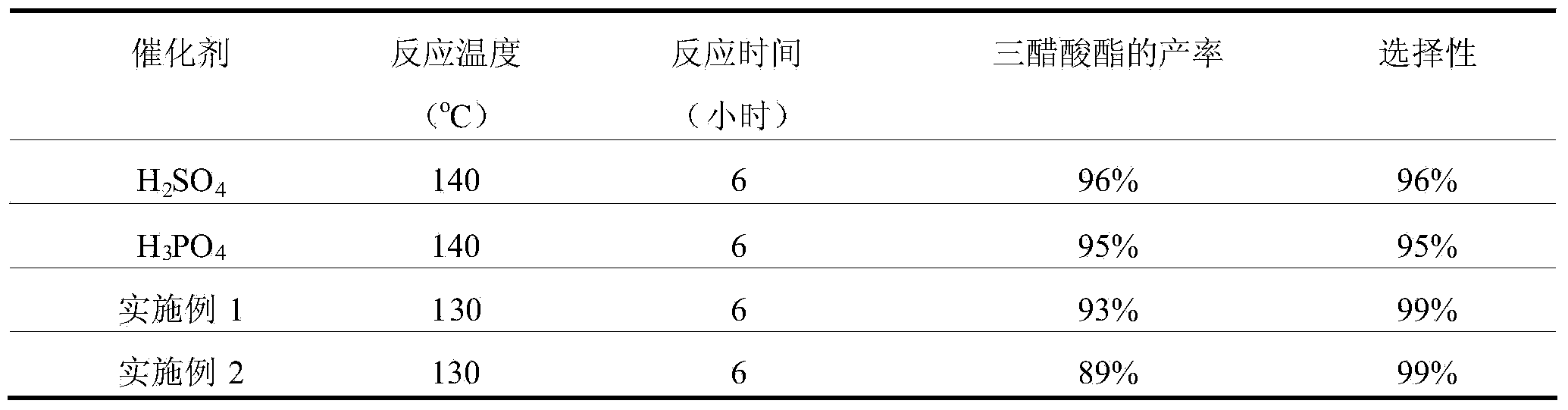

A technology of glycerol triacetate and hydrotalcite, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, and catalysts for physical/chemical processes, etc., to achieve the effects of high catalytic selectivity, guaranteed dispersion, and easy recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

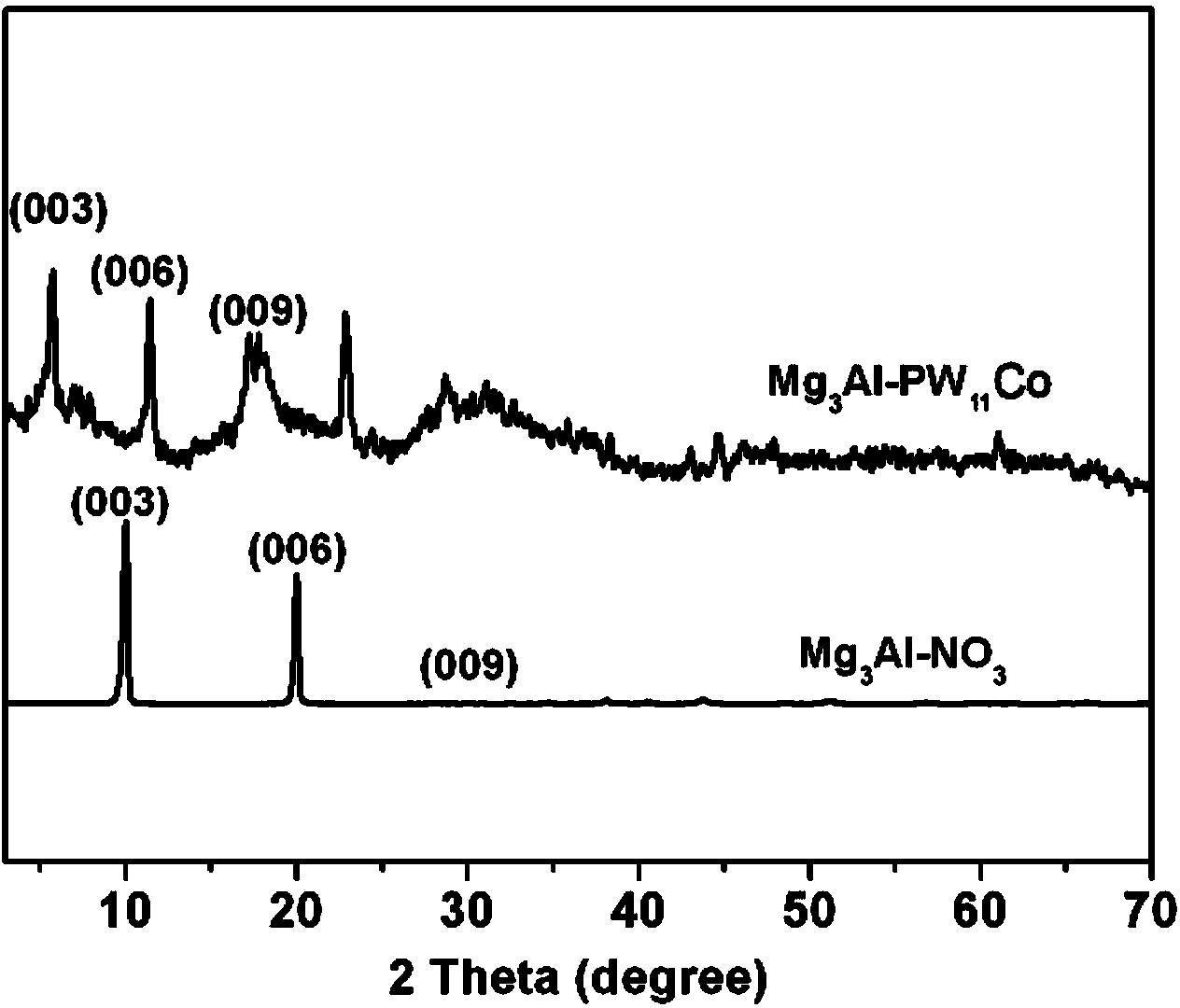

Embodiment 1

[0031] a) Take 15.4g (0.06mol) Mg(NO 3 ) 2 ·6H 2 O, 7.5g (0.02mol) Al(NO 3 ) 3 9H 2 O, 4.53g (0.053mol) NaNO 3 Mix, dissolve in 80ml to remove CO 2 A mixed salt solution was obtained in deionized water; 5.60g (0.133mol) NaOH was dissolved in 50ml to remove CO 2 Alkaline solution was obtained in deionized water; in N 2 Slowly drop the alkali solution into the mixed salt solution under protection, stir vigorously, and stop the drop when the pH is 6.0; then pour it into a high-pressure reaction kettle, age at 100°C for 18 hours, and then centrifugally wash to obtain a layer of hydrotalcite The divalent metal cation in is Mg 2+ , the trivalent metal cation is Al 3+ , the interlayer anion is NO 3 - , that is, magnesium aluminum hydrotalcite intercalated with nitrate, and the molar ratio of magnesium to aluminum is 3:1; the obtained undried 1g hydrotalcite is added to 65ml to remove CO 2 The hydrotalcite suspension was obtained in deionized water, and the hydrotalcite wa...

Embodiment 2

[0036] a) Take 15.4g (0.06mol) Mg(NO 3 ) 2 ·6H 2 O, 7.5g (0.02mol) Al(NO 3 ) 3 9H 2 O, 4.53g (0.053mol) NaNO 3 Mix, dissolve in 80ml to remove CO 2 A mixed salt solution was obtained in deionized water; 5.60g (0.133mol) NaOH was dissolved in 50ml to remove CO 2 Alkaline solution was obtained in deionized water; in N 2 Slowly drip the alkali solution into the mixed salt solution under protection, stir vigorously, and stop the dripping when the pH is 6.0; then pour it into a high-pressure reactor, age at 100°C for 18 hours, and then centrifuge and wash; the obtained 1g of hydrotalcite Add to 65ml to remove CO 2 The hydrotalcite suspension was obtained in deionized water, and the hydrotalcite was swelled for 5h; then 0.3M HNO 3 Adjust the pH to 6.0;

[0037] b) take 10gK 6 [SiW 11 CoO 39 ]·10H 2 O, dissolved in 50ml to remove CO 2 In deionized water, heat it to dissolve completely to obtain polyacid solution;

[0038] c) Drop the polyacid solution prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com