Technological method for color-coating line waste gas treatment

A technology of waste gas treatment and process method, which is applied in the direction of combustion method, surface pretreatment, and device for coating liquid on the surface, etc., which can solve problems such as unreasonable economic efficiency, and achieve the goals of reducing natural gas consumption, stabilizing heat energy, and saving energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

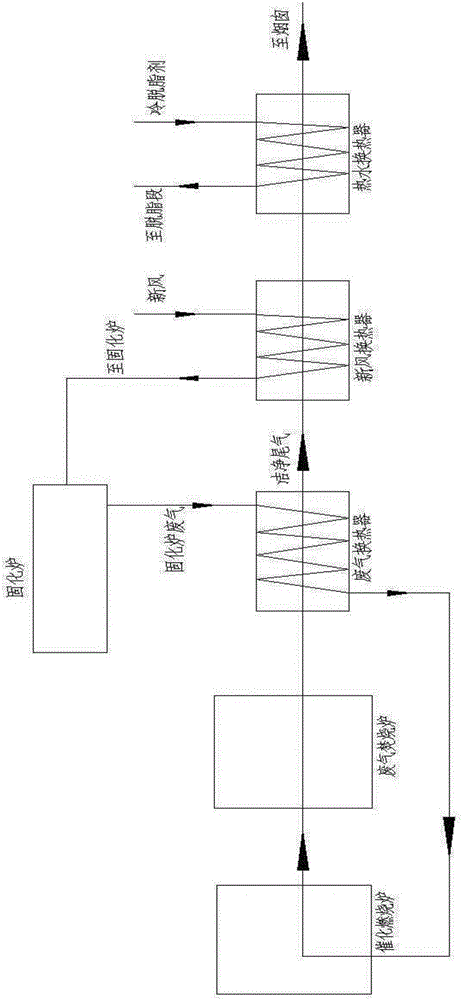

[0024] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

[0025] A kind of process method for the waste gas treatment of color coating line of the present invention can be described by the following steps:

[0026] 1) Pass the waste gas containing organic matter generated by the curing furnace into the waste gas heat exchanger, and preheat the waste gas in the waste gas heat exchanger to above 325°C, which is the ignition temperature of the organic waste gas, to about 400-450°C.

[0027] The initial heat of the exhaust gas heat exchanger comes from the heat obtained by burning natural gas in the catalytic combustion furnace and high-temperature incinerator. Burners are arranged in the high-temperature incinera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com