Method for continuous production of dimethyl succinylo succinate

A technology of dimethyl succinyl succinate and dimethyl succinate, which is applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc., can solve the problem of long time, high energy consumption, and production capacity Low-level problems, to achieve the effects of low cost, reduced energy consumption, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

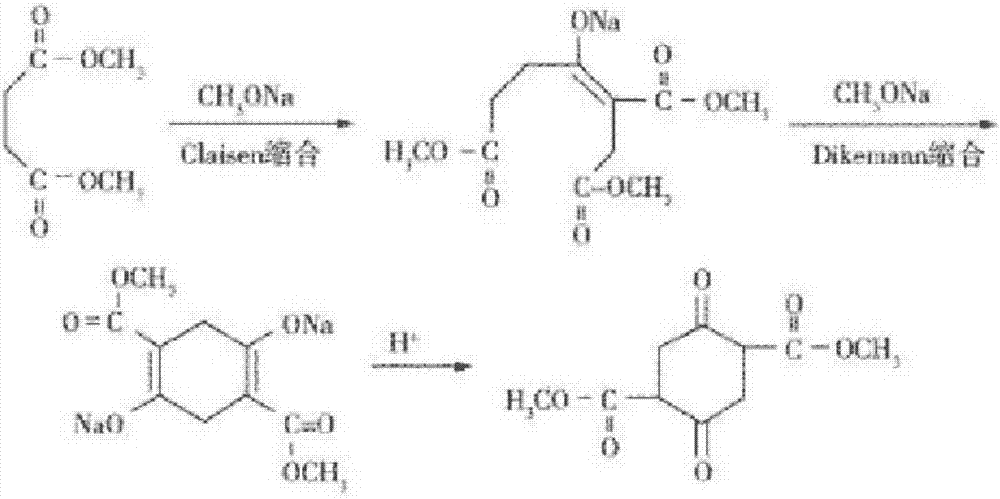

Image

Examples

Embodiment 1

[0019] A method for continuous production of dimethyl succinyl succinate, characterized in that it may further comprise the steps:

[0020] 1) Take dimethyl succinate, heat it to 105°C under the condition of nitrogen protection and stirring, keep it for 20min, and then use the ratio of dimethyl succinate to sodium methoxide as 16:5 (mL:g ) to the methanol solution of dimethyl succinate and sodium methoxide dropwise, continuously dropwise at 110°C;

[0021] 2) After the reactant is added dropwise to a certain liquid level, the material is continuously transferred to another reactor and kept warm to obtain a filter cake of dimethyl succinate sodium salt;

[0022] 3) adjust the pH to 2 with 17% mass fraction of dilute sulfuric acid solution, acidify, then filter the reactant, then wash the filter cake with water and dry to obtain dimethyl succinate.

[0023] On the basis of the above technical solutions, the following conditions are met:

[0024] The reaction site of step 1) is...

Embodiment 2

[0028] A method for continuous production of dimethyl succinyl succinate, characterized in that it may further comprise the steps:

[0029] 1) Take dimethyl succinate, heat it to 100°C under the condition of nitrogen protection and stirring, keep it for 20min, then use the ratio of dimethyl succinate to sodium methoxide as 16:5 (mL:g ) to the methanol solution of dimethyl succinate and sodium methoxide dropwise, continuously dropwise at 100°C;

[0030] 2) After the reactant is added dropwise to a certain liquid level, the material is continuously transferred to another reactor and kept warm to obtain a filter cake of dimethyl succinate sodium salt;

[0031] 3) adjust the pH to 2 with 15% by mass fraction of dilute sulfuric acid solution, acidify, then filter the reactant, then wash the filter cake with water and dry to obtain dimethyl succinate.

Embodiment 3

[0033] A method for continuous production of dimethyl succinyl succinate, characterized in that it may further comprise the steps:

[0034] 1) Take dimethyl succinate, heat it to 110°C under the condition of nitrogen protection and stirring, keep it for 20min, and then use the ratio of dimethyl succinate and sodium methoxide as 16:5 (mL:g ) to the methanol solution of dimethyl succinate and sodium methoxide dropwise, continuously dropwise at 120°C.

[0035] 2) After the reactant is added dropwise to a certain liquid level, the material is continuously transferred to another reactor and kept warm to obtain a filter cake of dimethyl succinate sodium salt;

[0036] 3) adjust the pH to 2 with 20% mass fraction of dilute sulfuric acid solution, acidify, then filter the reactant, then wash the filter cake with water and dry to obtain dimethyl succinate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com