Special cleaning agent for airplane enclosure and preparation method thereof

A cleaning agent and shell technology, applied in the directions of detergent compounding agents, detergent compositions, chemical instruments and methods, etc., can solve problems such as reducing work efficiency, operator health problems, etc., achieving simple proportioning and good rust prevention effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

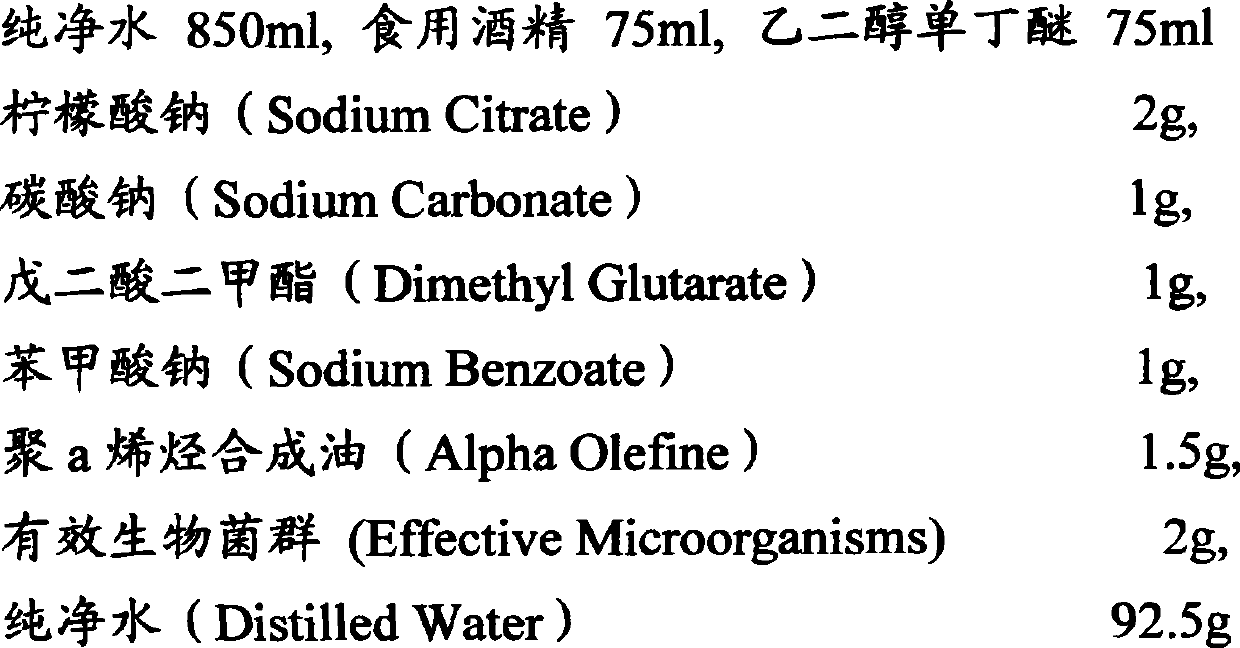

[0052] Mix organic acid salts, edible alcohol, benzoate, glycol ethers, polyethylene glycol, sodium carbonate, sodium metasilicate at a certain temperature silicate), sodium phosphate (sodium phosphate), dimethyl succinate (dimethyl succinate), benzotriazole (Benzotriazole) and other raw materials are mixed in a certain proportion and stabilized to produce the cleaning agent of the present invention.

[0053] The specific ratio is:

[0054] Configure the following raw materials according to mass percentage:

[0055] Sodium Benzoate 0.2-0.5%

[0056] Sodium metasilicate 0.2-0.5%

[0057] Sodium carbonate 0.2-0.5%

[0058] Sodium citrate 0.2-0.5%

[0059] Sodium Phosphate 0.2-0.5%

[0060] Dimethyl succinate 0.2-0.5%

[0061] Benzotriazole 0.2-0.5%

[0062] Ethylene glycol monobutyl ether 7.5-15%

[0063] Polyethylene glycol 5-10%.

[0064] Or, configure the following raw materials according to mass percentage:

[0065] Sodium Benzoate 0.2-0.4%

[0066] Sodium metasil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com