Method for preparing diester succinate by esterifying diammonium succinate

A technology of diammonium succinate and succinate diester, which is applied in the field of preparing dimethyl succinate, can solve the problems of difficult acquisition of main raw materials, long product separation process, unfavorable industrial production, etc., and achieve good product quality , less corrosion, and the effect of inhibiting by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

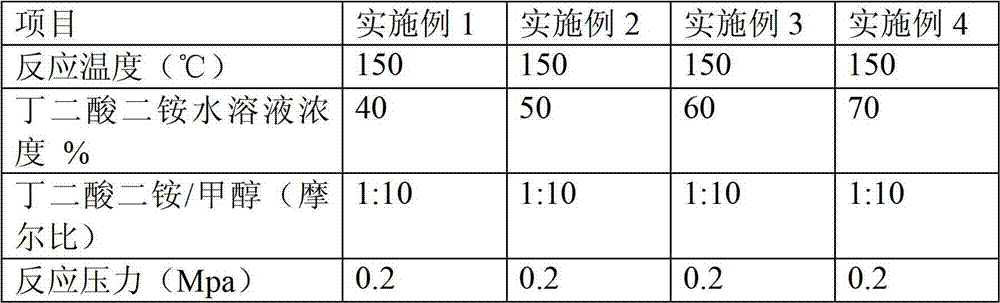

[0029] 7.6g diammonium succinate is added to 11.4% water, and the solution that obtains 19g diammonium succinate mass concentration is 40%, this solution and 20ml methyl alcohol co-flow join in the reactor, add catalyzer simultaneously (SiO 2 -Al 2 o 3 ) 0.6g, feed nitrogen into the reactor to increase the pressure inside the reactor to 0.2Mpa. The reaction temperature is 120° C., and the reaction time is 10 h.

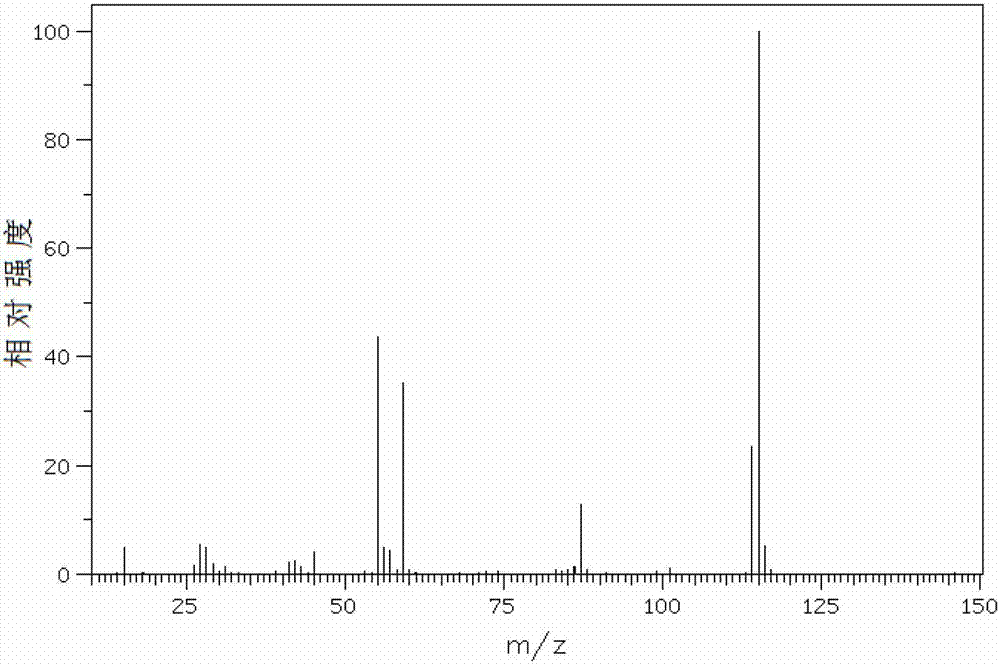

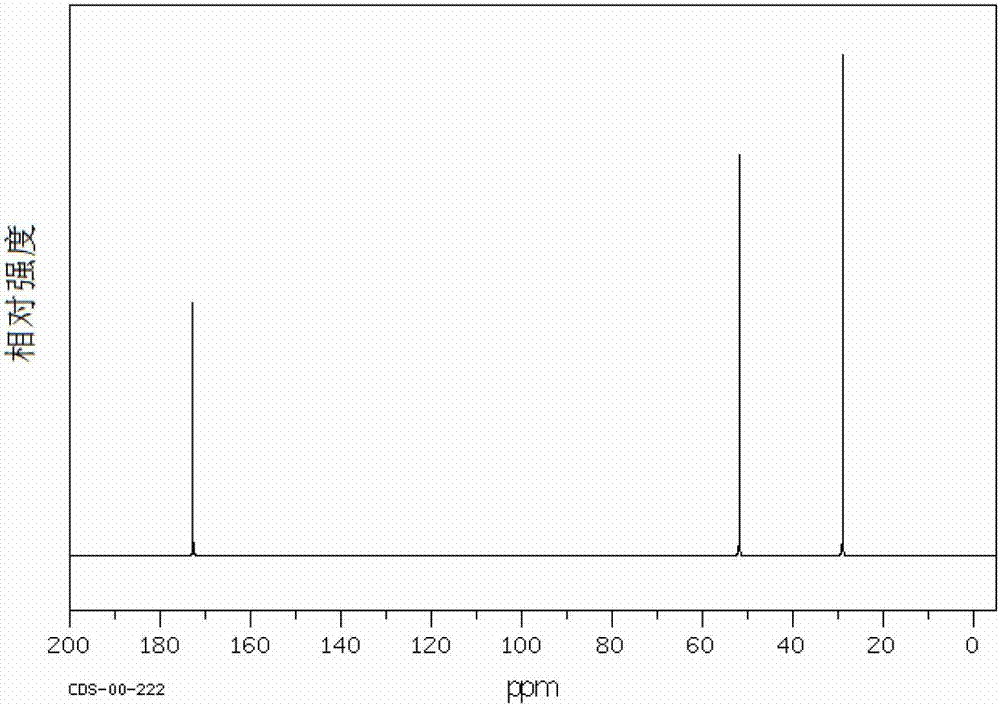

[0030] The number of plates in the succinic acid diester azeotropic distillation tower is 15, 16g of ethyl acetate is added as an entrainer, the reflux ratio is 1, the temperature at the top of the tower is 62-65°C, and the temperature at the bottom of the tower is 90-100°C . The mass spectrogram of the obtained succinic acid diester is as follows figure 1 As shown, the NMR spectrum is shown as figure 2 shown.

[0031] See Table 1 for the experimental results.

Embodiment 2

[0033] 7.6g diammonium succinate is added to 7.6 g of water to obtain 15.2g diammonium succinate mass concentration is a solution of 50%, the solution and 20ml methyl alcohol are added to the reaction kettle concurrently, while adding catalyst (SiO 2 -Al 2 o 3 ) 0.6g, feed nitrogen into the reactor to increase the pressure inside the reactor to 0.2Mpa. The reaction temperature is 150° C., and the reaction time is 10 h.

[0034] The number of plates in the succinic acid diester azeotropic distillation column is 15, 16g of ethyl acetate is added as an entrainer, the reflux ratio is 1, the temperature at the top of the tower is 60-65°C, and the temperature at the bottom of the tower is 90-100°C . The mass spectrogram of the obtained succinic acid diester is as follows figure 1 As shown, the NMR spectrum is shown as figure 2 shown.

[0035] See Table 1 for the experimental results.

Embodiment 3

[0037] 7.6g diammonium succinate is added to 5.07 g of water to obtain 12.67g diammonium succinate mass concentration is a solution of 60%, the solution and 20ml methyl alcohol are added to the reaction kettle in parallel, while adding catalyst (SiO 2 -Al 2 o 3 ) 0.6g, feed nitrogen into the reactor to increase the pressure inside the reactor to 0.2Mpa. The reaction temperature is 150° C., and the reaction time is 10 h.

[0038] The number of plates of the succinate azeotropic distillation column is 15, 16g of ethyl acetate is added as an entrainer, the reflux ratio is 1, the temperature at the top of the tower is 60-65°C, and the temperature at the bottom of the tower is 90-100°C. The mass spectrogram of the obtained succinic acid diester is as follows figure 1 As shown, the NMR spectrum is shown as figure 2 shown.

[0039] See Table 1 for the experimental results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com