Process for preparation of quinacridone series pigments

A technology of quinacridone and dihydroquinacridone, which is applied in quinacridone, chemical instruments and methods, azo dyes, etc., can solve the problems of many by-products, complex process, and large influence of pigment color light, etc., to achieve The effect of product quality assurance, simplification of process and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

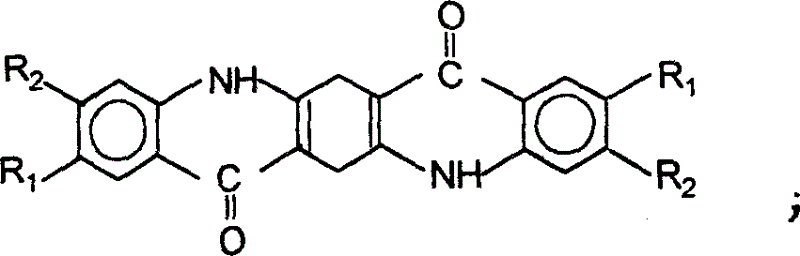

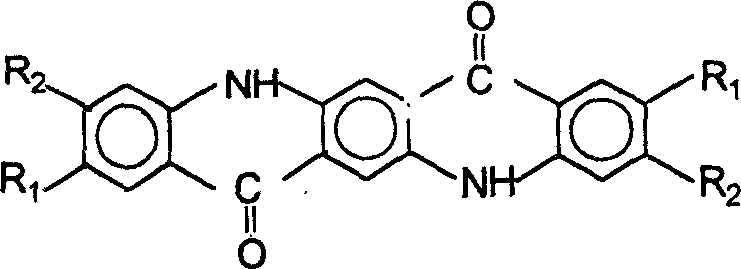

[0025] Preparation of Quinacridone

[0026] Step 1, condensation

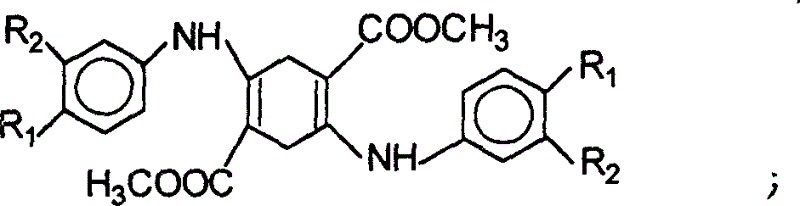

[0027] Method 1: Dissolve 30 g of dimethyl succinyl succinate in 150 ml of ethanol, add 3 ml of concentrated hydrochloric acid and 26 g of aniline, and heat and reflux for 5 hours under nitrogen protection. Precipitate a large amount of orange-yellow solid, filter after cooling, wash the excess aniline with 0.5% dilute hydrochloric acid, wash with water until neutral, dry to obtain 1,4-(N-phenyl)-2,5-dicarboxylic acid dimethyl ester , the yield is 92%, and the content is 96-97%.

[0028] Method 2: Dissolve 30 g of dimethyl diacylsuccinate in 150 ml of ethanol, add 3 ml of concentrated hydrochloric acid and 30 g of p-methylaniline, and heat up and reflux for 5 hours under nitrogen protection. Precipitate a large amount of yellow-green solid, filter after cooling, wash the excess methylaniline with 0.5% dilute hydrochloric acid, wash with water until neutral, and dry to obtain 1,4-(N-p-tolylamino)-2,5-dicarboxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com