Low-temperature non-glue packaging process for FBG (fiber brag grating) high-temperature sensor

A high-temperature sensor and packaging technology, applied to instruments, thermometers, measuring devices, etc., to achieve the effects of good linearity, low cost of heating equipment, and low operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

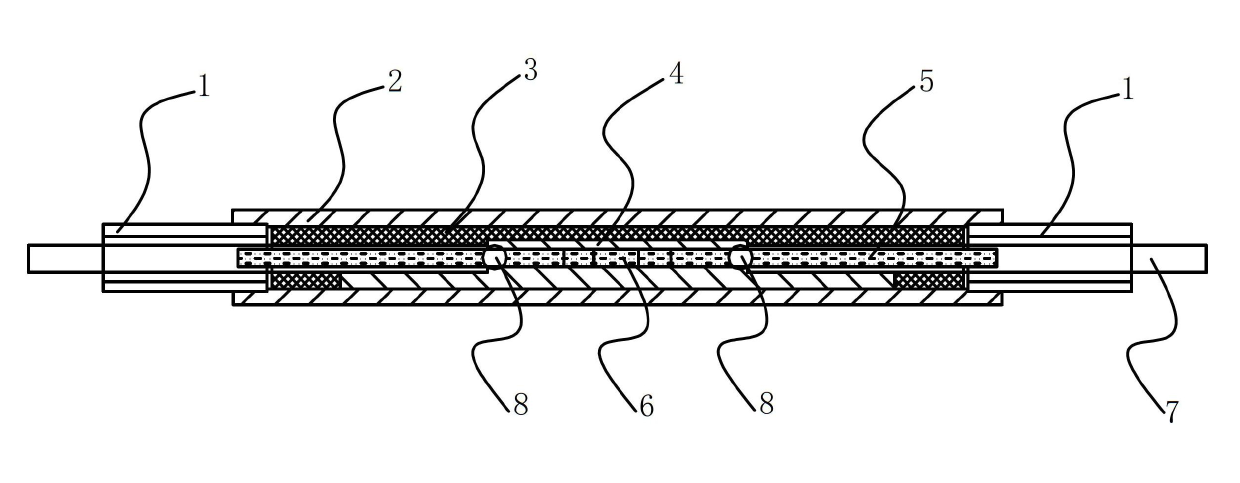

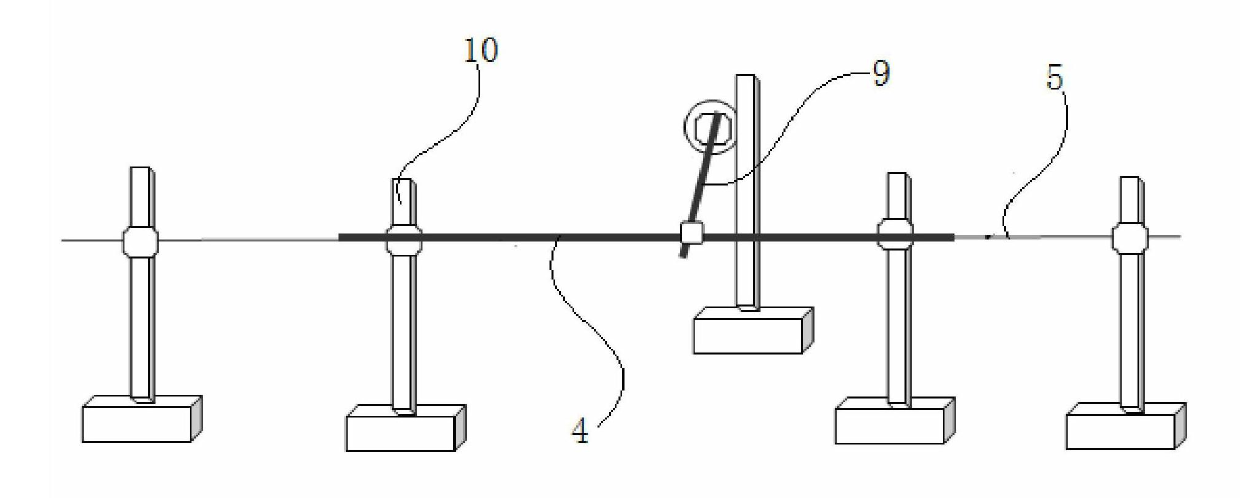

[0041] see figure 1 and figure 2 As shown, in this embodiment, a low-temperature gel-free packaging process for FBG high-temperature sensors comprises the following steps:

[0042] a. Heat the electric soldering iron 9 to adjust its temperature to between 350°C and 400°C, and install the electric soldering iron 9 on the support 10 of the welding console;

[0043] b. Put the grating 6 into the semi-cylindrical stainless steel pipe 4. The grating 6 is a high-temperature-resistant fiber Bragg grating with a polyimide coating layer. Cylindrical stainless steel pipe 4 has a complete cylindrical part in the middle, and semi-cylindrical parts at both ends; its specifications are: inner diameter 1mm, outer diameter 2.2mm, length 70mm, the middle complete cylindrical part is 30mm, and the cutting depth of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com