Automatic tin supplying electric iron

An electric soldering iron and tin supply technology, applied in soldering irons, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult control of solder flow, complicated structure, inconvenient operation, etc., to facilitate mass production, improve production efficiency, and facilitate operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

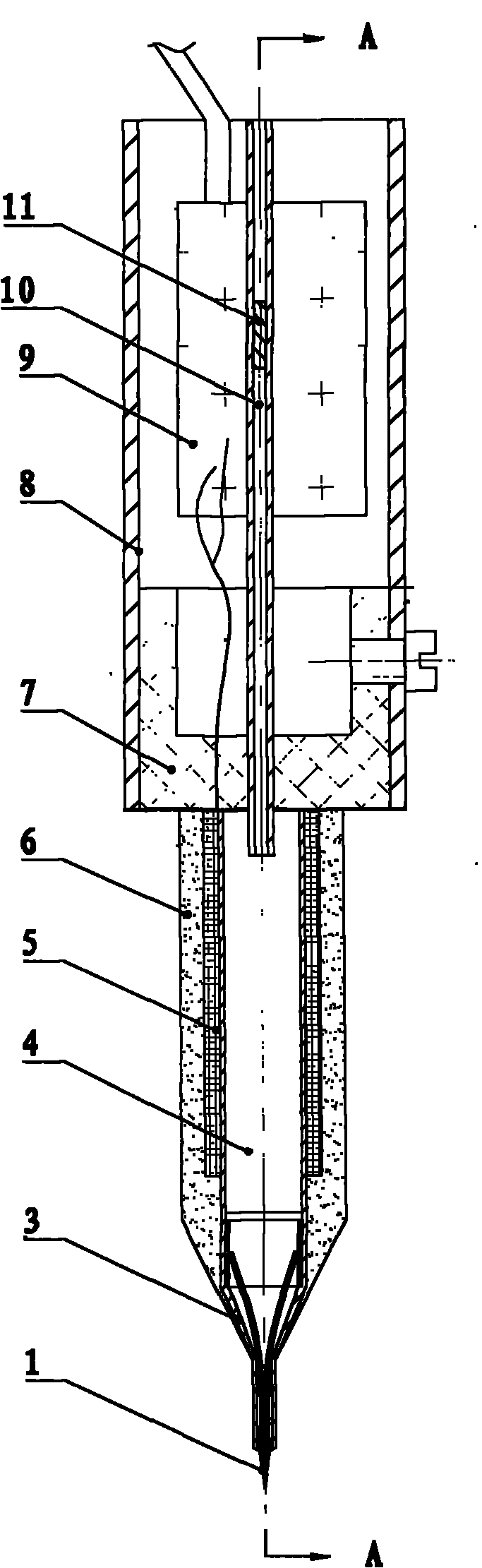

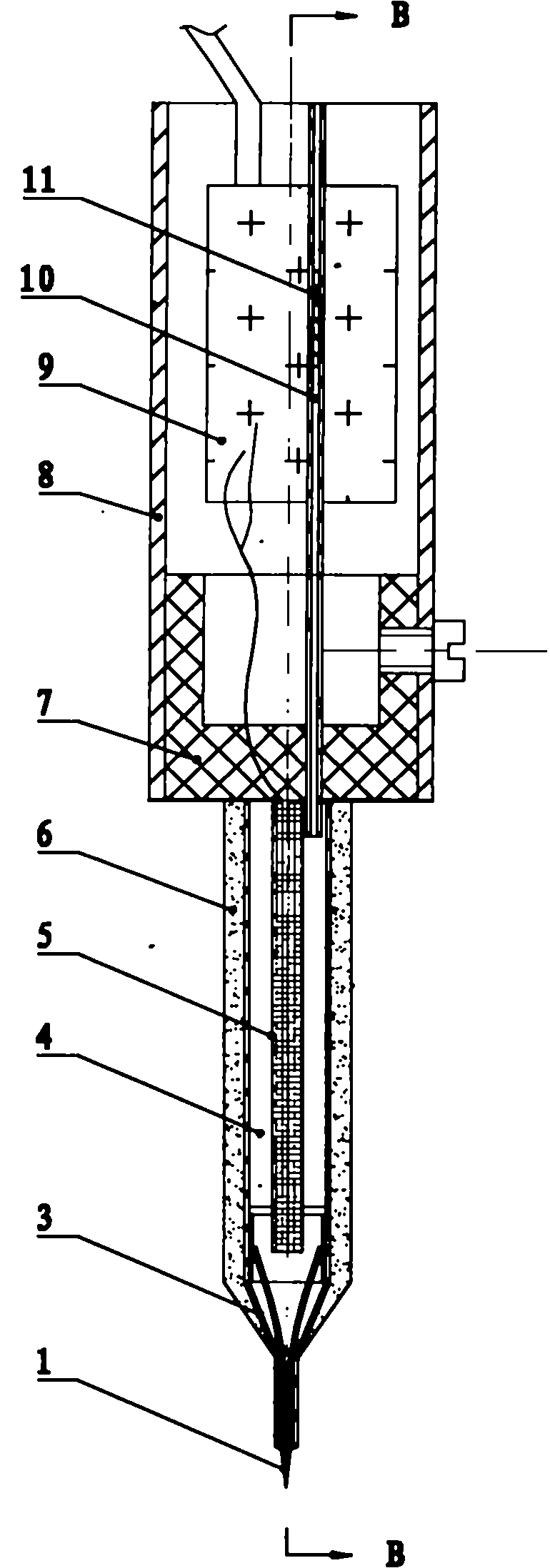

[0018] Embodiment 1: The automatic tin-supply electric soldering iron described in this embodiment includes a wire feeding device, a heating device, a handle 8 and a soldering iron tip, and also includes a tin melting cavity 4, which is located between the handle 8 and the soldering iron tip , the heating device is located inside or outside the tin melting chamber 4, the heating device is used to heat the tin melting chamber 4, and then melts the solder in the cavity; the wire feeding device is used to send the solder wire into the tin melting chamber 4 , the outlet of the melting tin cavity 4 communicates with the inlet of the soldering iron tip; the molten solder enters through the inlet of the soldering iron tip and flows out from the outlet.

[0019] When the automatic tin-supply electric soldering iron described in this embodiment is actually produced, a heat insulating device 7 should be fixed between the handle 8 and the tin melting chamber 4, so as to prevent the heat g...

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and the automatic tin-supply electric soldering iron described in Embodiment 1 is that the wire feeding device is located in the handle 8 .

specific Embodiment approach 3

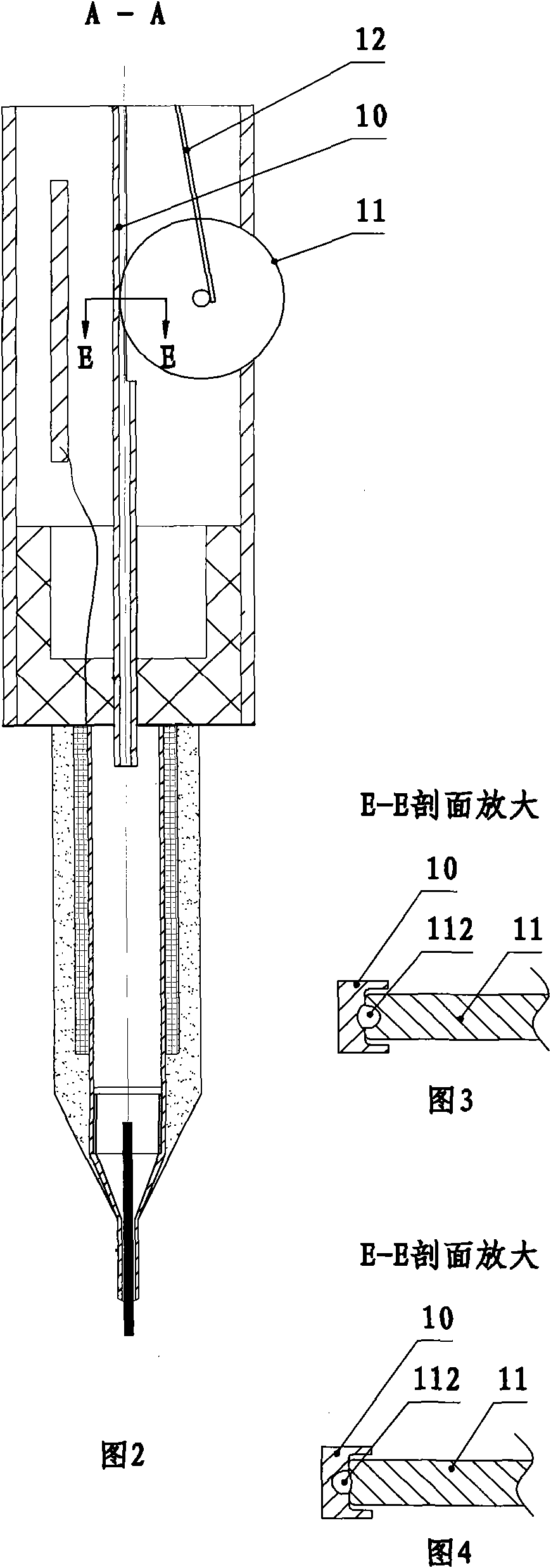

[0021] Specific embodiment three: the difference between this embodiment and the automatic tin-supply electric soldering iron described in specific embodiment two is that the wire feeding device is composed of a wire feeding wheel 11, an elastic device and a wire feeding guide rail, and the axle of the wire feeding wheel 11 It is fixedly connected with one end of the elastic device, and the elastic device presses the edge of the wire feed wheel 11 on the wire feed guide rail, and there is a wire feed channel between the wire feed wheel 11 and the wire feed guide rail, and the wire feed channel can be connected with Solder wire interference fit, part of the edge of the wire feed roller 11 is exposed outside the handle 8, one end of the wire feed guide is located at the edge of the handle, the hard guide is connected to the outside, and the other end of the wire feed guide is located in the melting chamber 4 entrances.

[0022] see figure 2 , is a specific embodiment of the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com