Multihead temperature control electric soldering iron

An electric soldering iron and multi-head technology, applied in the direction of soldering iron, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency, shortened service life, power consumption, etc., and achieve the goal of shortening working time, prolonging service life and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

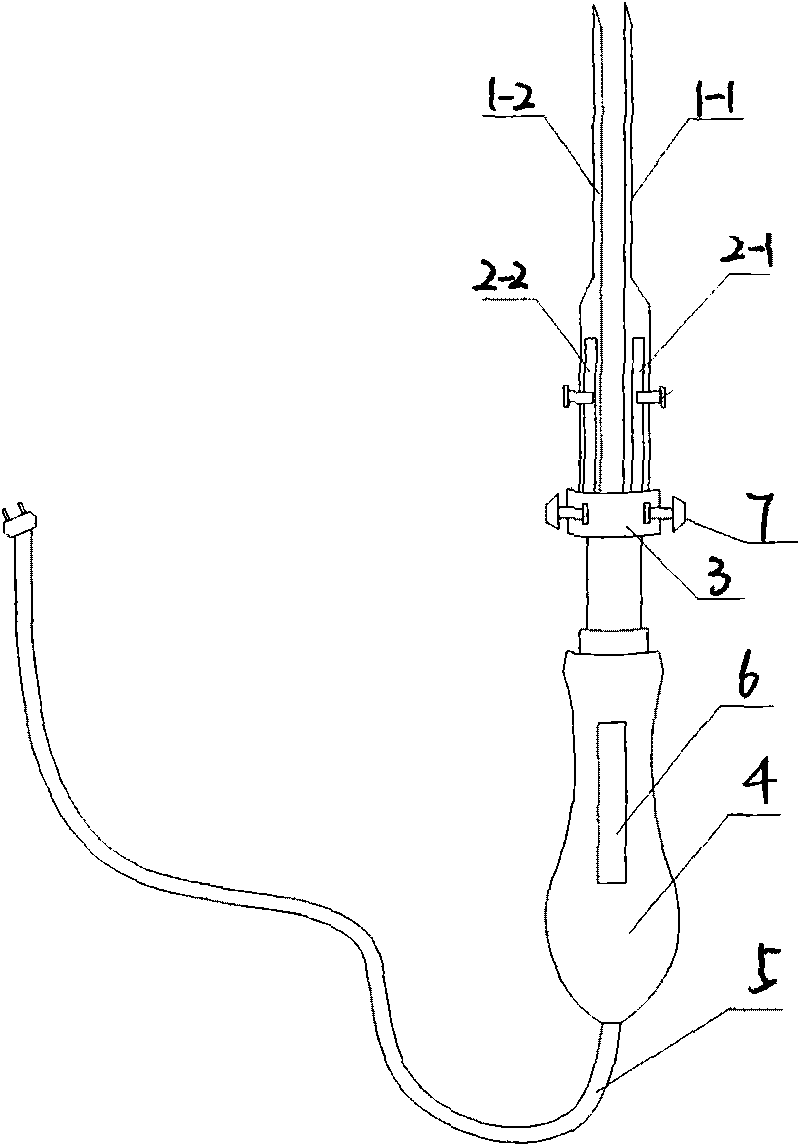

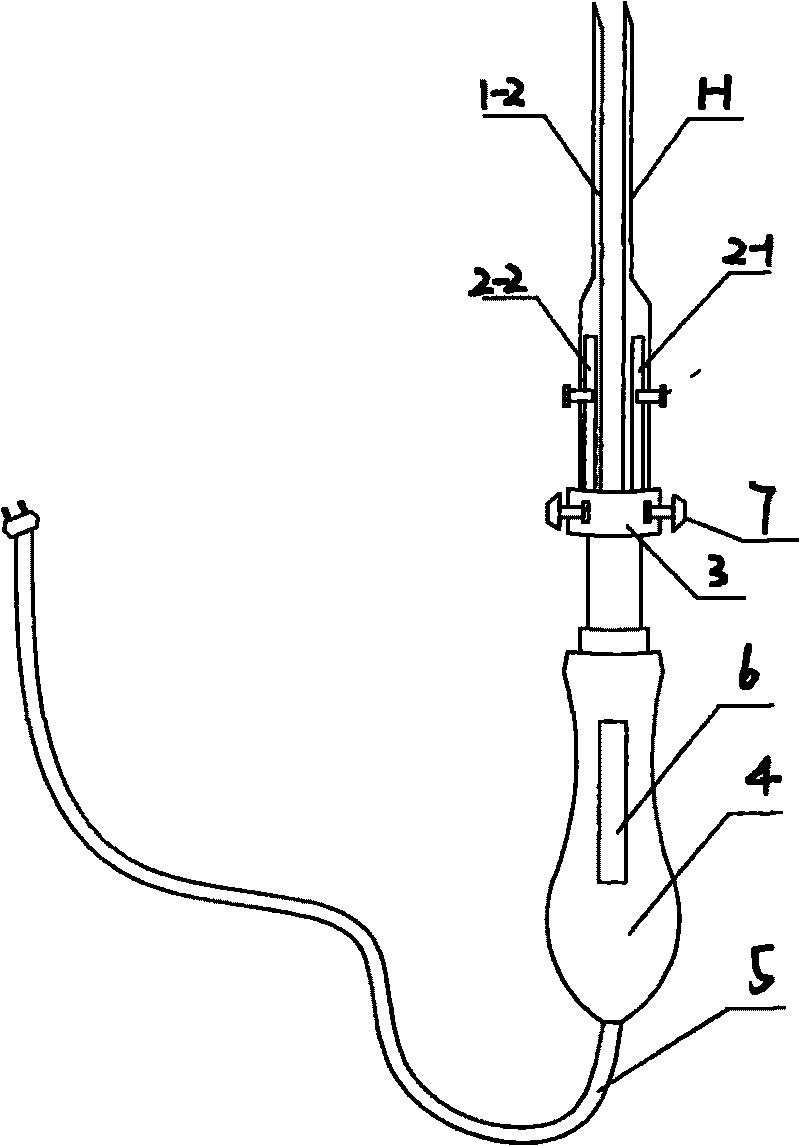

[0015] Such as figure 1 As shown, the multi-head temperature-controlled electric soldering iron in this embodiment includes two soldering iron heads 1-1, 1-2, two heating cores 2-1, 2-2, connecting rod 3, handle 4 and power cord 5, wherein The heating core 2 is located inside the cavity of the soldering iron tip 1. There are fixing screws on the soldering iron tip 1-1 and 1-2, which are used to fix the heating core 2 and the soldering iron tip 1 into one body. Both the heating core 2 and the soldering iron tip 1 are fixed on the On the connecting rod 3, the connecting rod 3 is fixed on the handle 4, a temperature control button is provided on the surface of the handle 4, and a temperature control circuit 6 is arranged inside it, and an adjustment is provided between the soldering iron tip 1-1, 1-2 and the connecting rod 3 Knob 7 is used to adjust the distance between the soldering iron tips.

Embodiment 2

[0017] The multi-head temperature-controlled electric soldering iron in this embodiment has the same structure as that in Embodiment 1, except that the number of soldering iron heads is four.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com