Pen type automatic soldering tin electric soldering iron

An automatic soldering and electric soldering iron technology, applied in soldering irons, tin feeding devices, welding equipment, etc., can solve the problems of waste of electric energy, the supply of liquid solder cannot be strictly controlled, etc., and achieve simple and convenient operation, reduce welding labor intensity, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

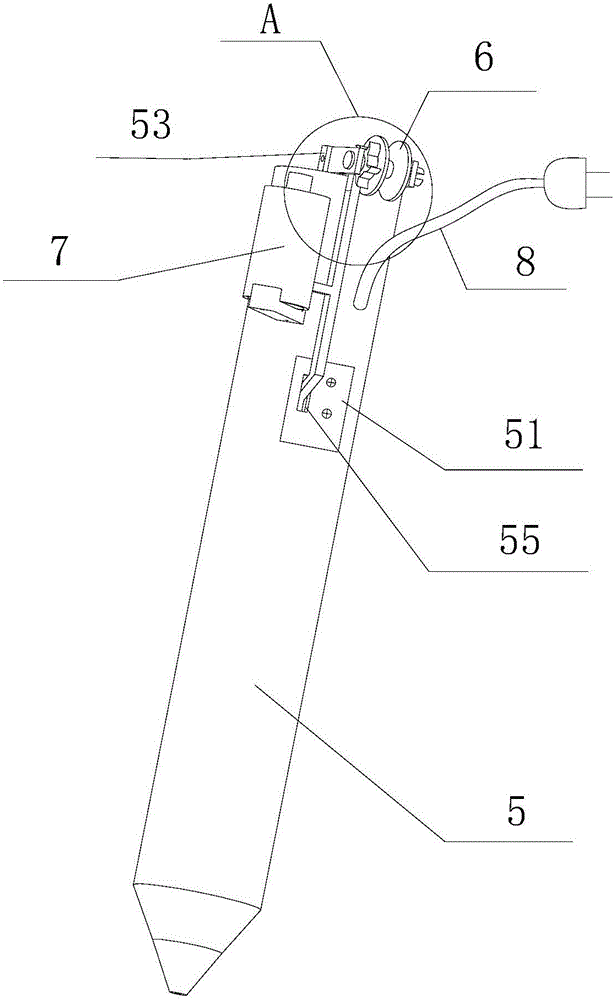

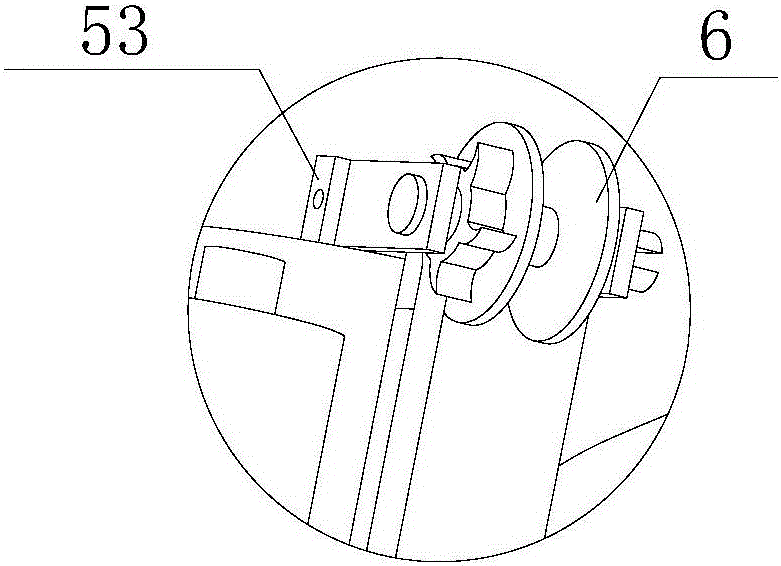

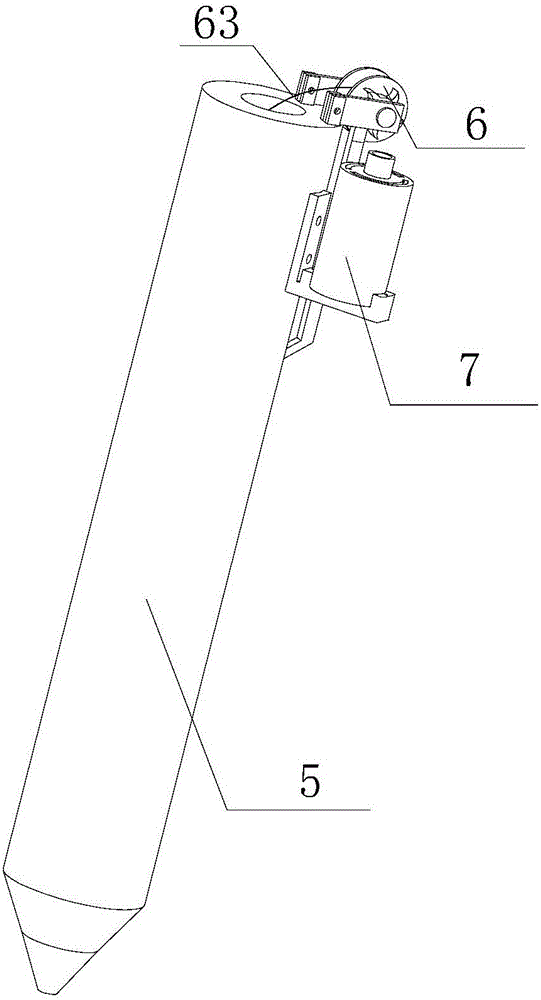

[0041] Combine below Figure 1-Figure 15 Specific embodiments of the present invention are described in further detail:

[0042] The pen-type automatic soldering iron includes a cylinder, a heating device, a control switch device 7 and an automatic wire feeding device 6 (such as figure 1shown). The cylinder body includes a sleeve 5, a hollow porcelain tube 2 inside the sleeve 5, and an insulation layer 4 between the hollow porcelain tube 2 and the sleeve 5, and a control switch device 7 and an automatic wire feeding device 6 are located in the sleeve 5. above. The insulation layer 4 has the function of thermal insulation, and the sleeve 5 protects the insulation layer 4 and the hollow porcelain tube 2 to prevent the electric soldering iron from being damaged. We use the rubber sleeve as the most preferred solution for the sleeve 5. The heating device includes a power cord 8, an annular insulating plate 3, a resistance wire 1 and a heating switch 9. The resistance wire 1 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com