Water leaving grid and mounting structure thereof

A technology for installing structures and lattices, applied in transportation and packaging, trucks, railway car bodies, etc., can solve the problems of small ventilation area, low service life, insufficient ventilation, etc., to achieve high structural strength, improve service life, reduce The effect of welding workload and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

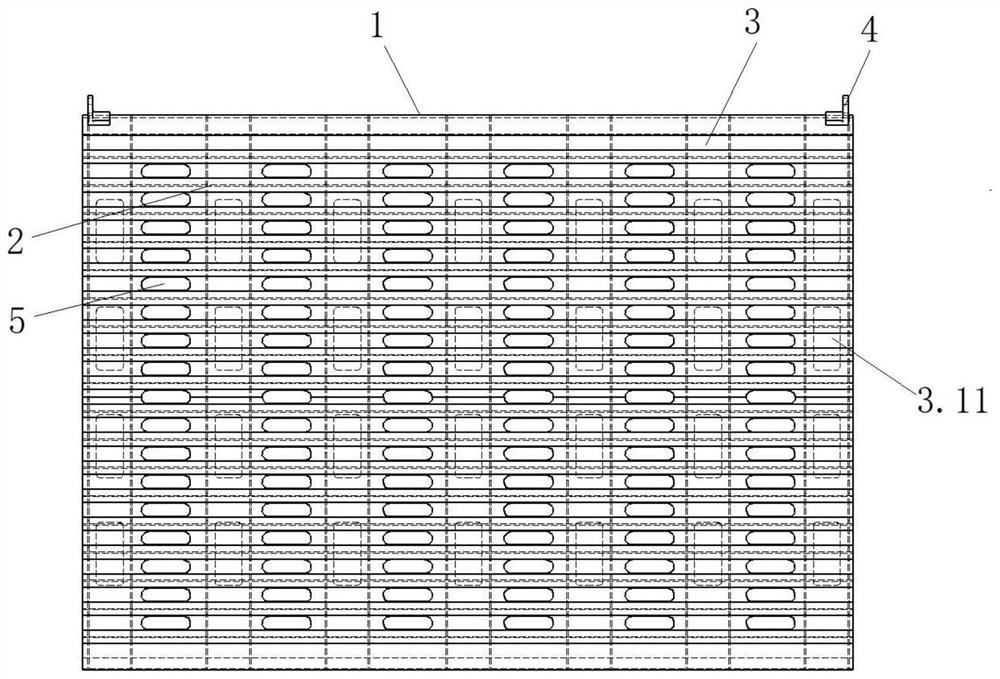

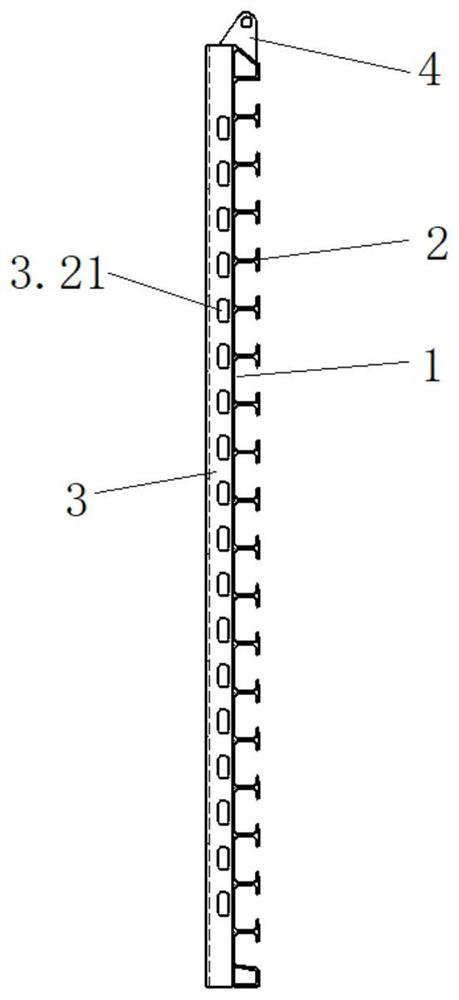

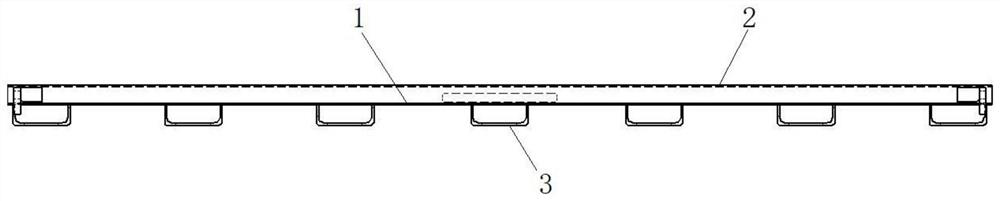

[0031] Such as Figure 1 ~ Figure 3 The water-free grid shown includes a floor 1, and a plurality of T-shaped rails 2 are integrally formed on the top of the floor 1. The floor 1 and the T-shaped rails 2 are integrally formed by extrusion of aluminum alloy. The T-shaped overall extruded structure simplifies the manufacturing process, reduces the welding workload and labor intensity, significantly improves the structural strength, and greatly improves the service life.

[0032] In the above technical solution, several supporting beams 3 are arranged under the floor 1 ; and a support 4 for hinged connection with the vehicle body is also arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com